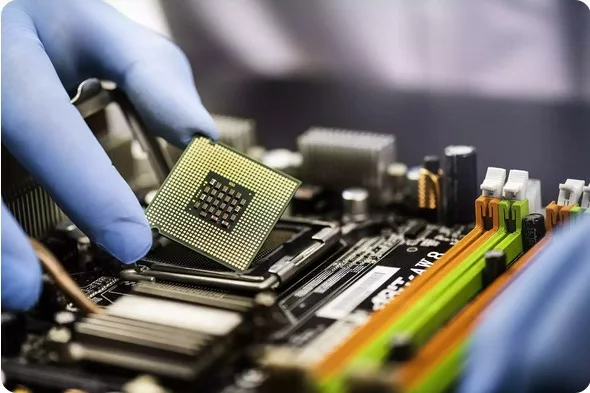

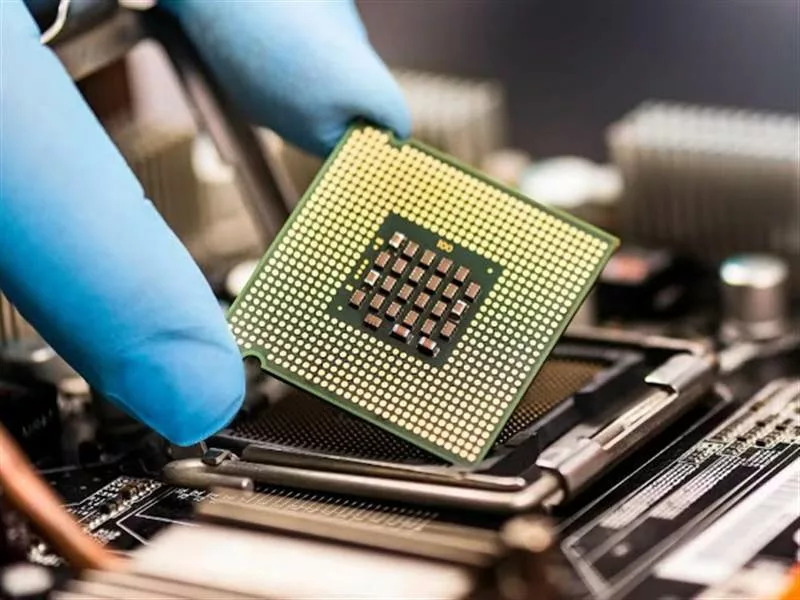

Semiconductor Design and Manufacturing

Semiconductor Design and Manufacturing

“We are very satisfied with the quality and efficiency brought by the IDEA team. They effectively helped us address the design personnel shortage, accelerate production progress, and reduce design and manufacturing costs. With their outstanding capabilities, we decided to expand long-term cooperation, including inviting them to participate in intensive training in Japan.”

A startup in the semiconductor design and manufacturing sector in Japan, with only 3 years of experience, consists of a small group of engineers capable of designing from concept, programming, and assembly. However, this company faces difficulties due to a shortage of design personnel to carry out detailed designs and produce manufacturing drawings, which are essential to complete the production process. This issue increases costs and prolongs product completion time.

Solution to the Design Personnel Shortage

IDEA Technology provided a team of 6 full-time engineers over 3 years to support the digitization of product designs. The initial team consisted of 3 members, gradually expanding to 6 to optimize the workflow.

IDEA’s team closely collaborated with the client through weekly meetings to ensure prompt feedback and design adjustments as required. The client also directly trained and guided the team, enhancing their understanding of design processes and standards, ensuring consensus and high efficiency in work. Semiconductor Design

Based on the concept received from the client, IDEA’s design engineers completed detailed drawings while optimizing the design to simplify the manufacturing and assembly process. Additionally, we supported the client in building assembly and inspection manuals, ensuring a smooth and quick production process.

Thanks to IDEA’s support, the client was able to accelerate production progress and significantly reduce costs related to detailed design personnel. Our optimized and simplified designs not only met technical requirements but also helped reduce machining and installation costs. Furthermore, the rapid development of manuals helped the client quickly bring products to market.

The client expressed high satisfaction with the quality of work and efficiency brought by IDEA’s team. Consequently, they decided to expand long-term cooperation with IDEA.

In the next step, the client invited IDEA’s employees to Japan for an intensive 6-month training course. During this time, IDEA’s employees will directly participate in the assembly and completion of the client’s machine manufacturing projects. This helps enhance design capabilities while preparing IDEA’s personnel to take over the entire design process from concept to finished product.

After completing the training in Japan, IDEA’s employees will return to Vietnam and continue working exclusively for the client. As a “strong arm” from Vietnam, they will help the client solve the urgent issue of design personnel shortage, a pressing problem in Japan today. Semiconductor Design

Conclusion

IDEA Technology not only helps the client solve detailed design issues but also builds a long-term strategic partnership. With improved capabilities and intensive training, IDEA’s team will continue to support the client as an important part of the design supply chain, helping the client reduce costs and maintain competitiveness amid the shortage of design personnel in Japan.

Semiconductor Design

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.