LACK OF REAL-TIME DATA FOR DECISION-MAKING

LIMITED PRODUCTION & QUALITY CONTROL

EXCEL IS NOT ENOUG FOR SHOP FLOOR MANAGEMENT

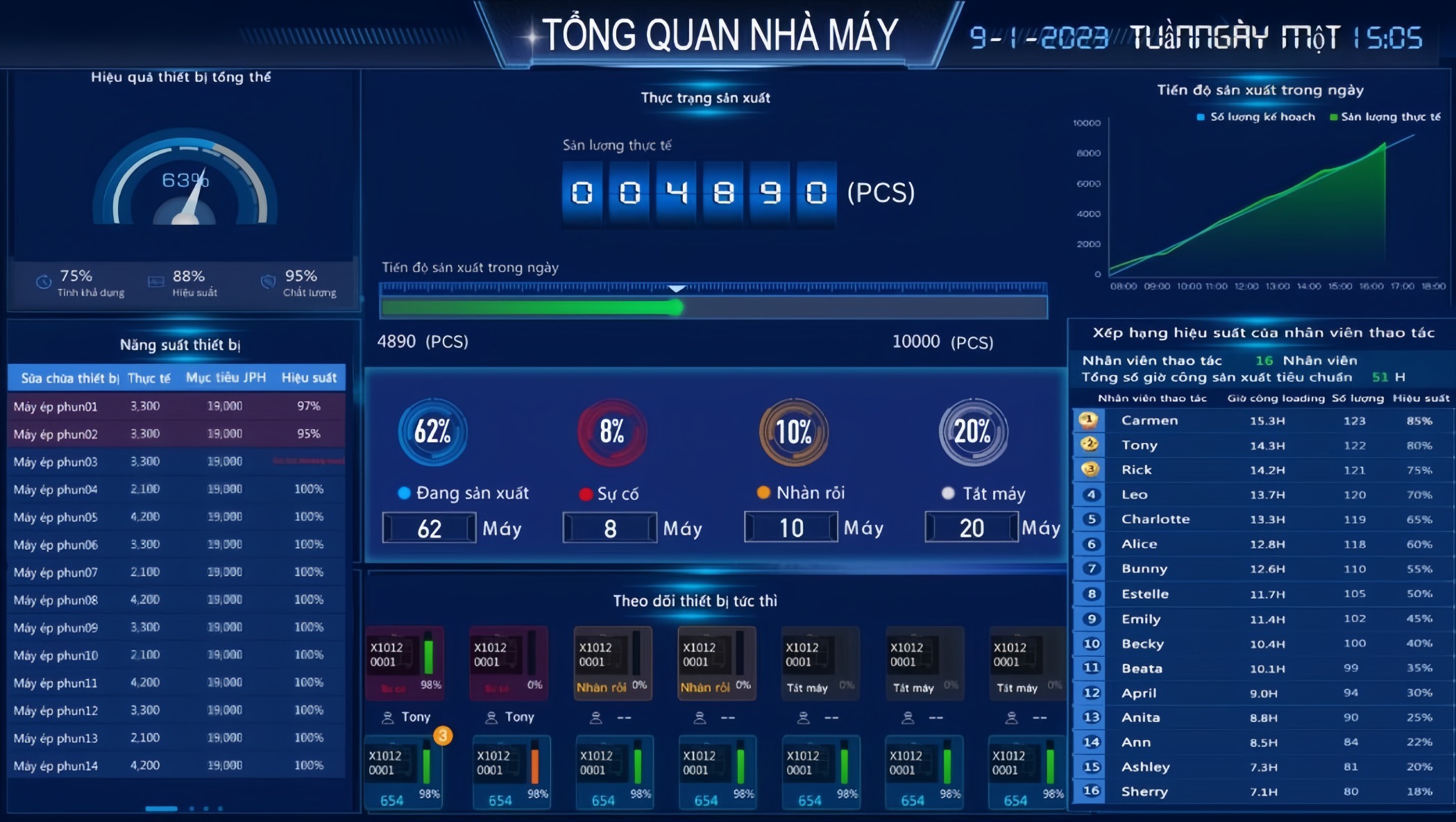

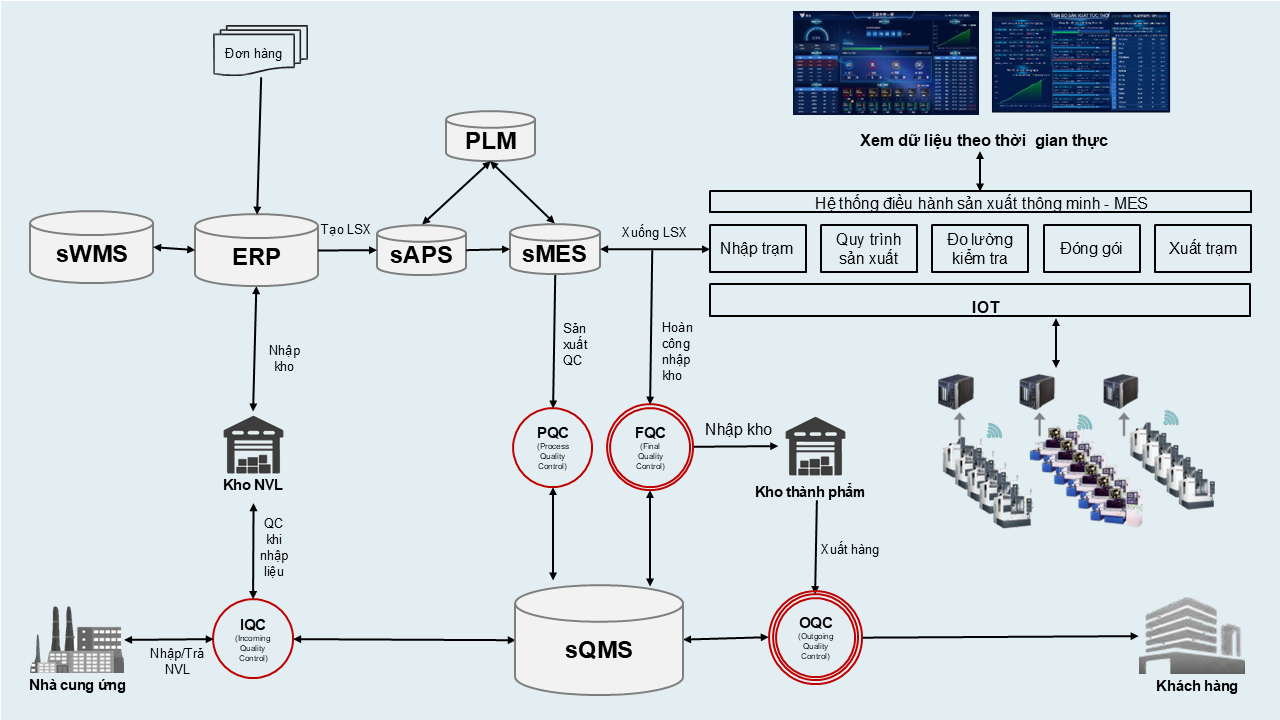

The system captures data directly from production equipment, manufacturing lines, and IoT sensors, ensuring up-to-date and accurate information at all times.

From raw materials to finished goods, the MES system manages the entire production lifecycle—from material input and process tracking to quality inspection and final product output. This enables manufacturers to optimize production planning, reduce material waste, ensure consistent product quality, and meet traceability requirements.

The system offers intuitive dashboards and comprehensive analytics that cover key areas such as equipment performance (OEE), labor productivity, product quality, and production costs. These actionable insights enable managers to make quick, strategic, and data-driven decisions, eliminating the need to rely on assumptions.

Our palletizing solutions integrate with:

Key MES tasks in equipment management include:

These tasks help manufacturers improve equipment efficiency, reduce downtime, and optimize production processes.

For legacy machines, MES solutions typically use:

This approach enables MES to monitor machine status, track output, and analyze performance without replacing the entire machine.

MES data accuracy is ensured through:

This ensures reliable data for monitoring, KPI calculation, and equipment performance optimization.