Precision Machining of Runner Components for Small-Scale Turbine Simulation Systems

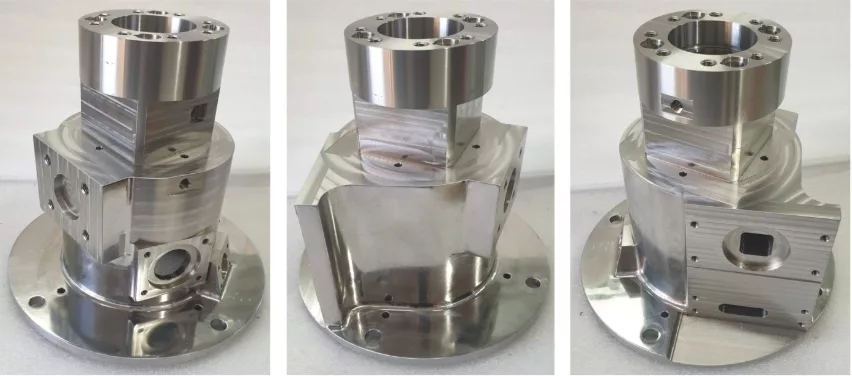

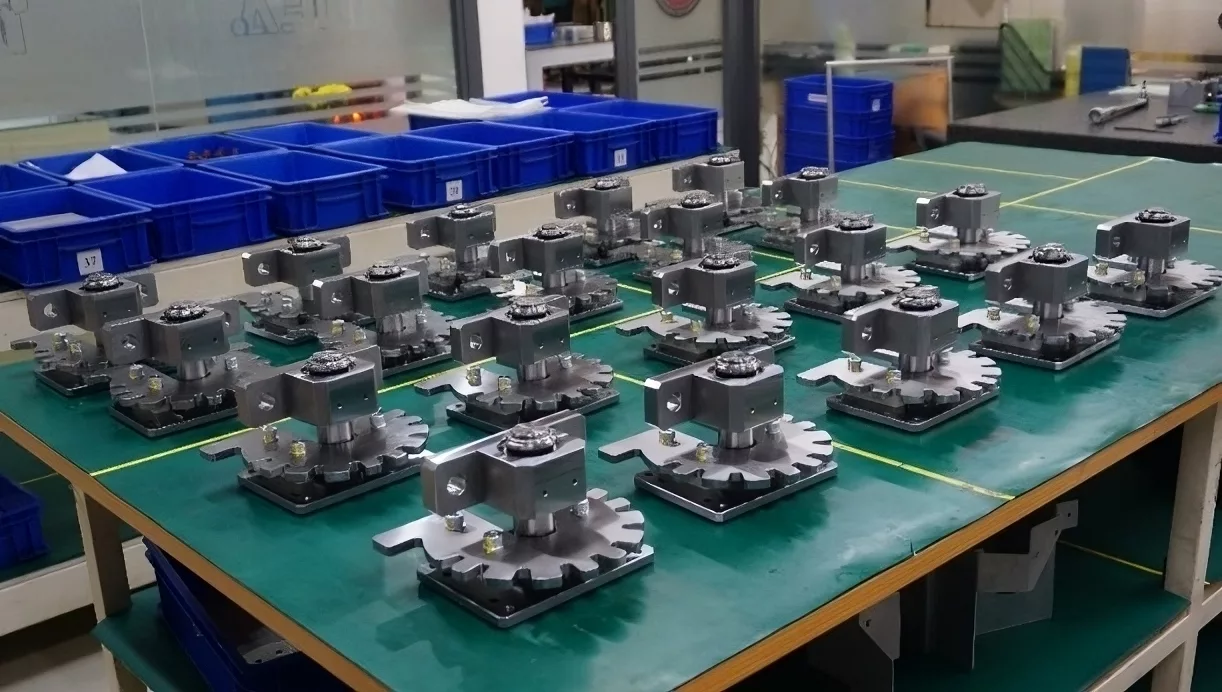

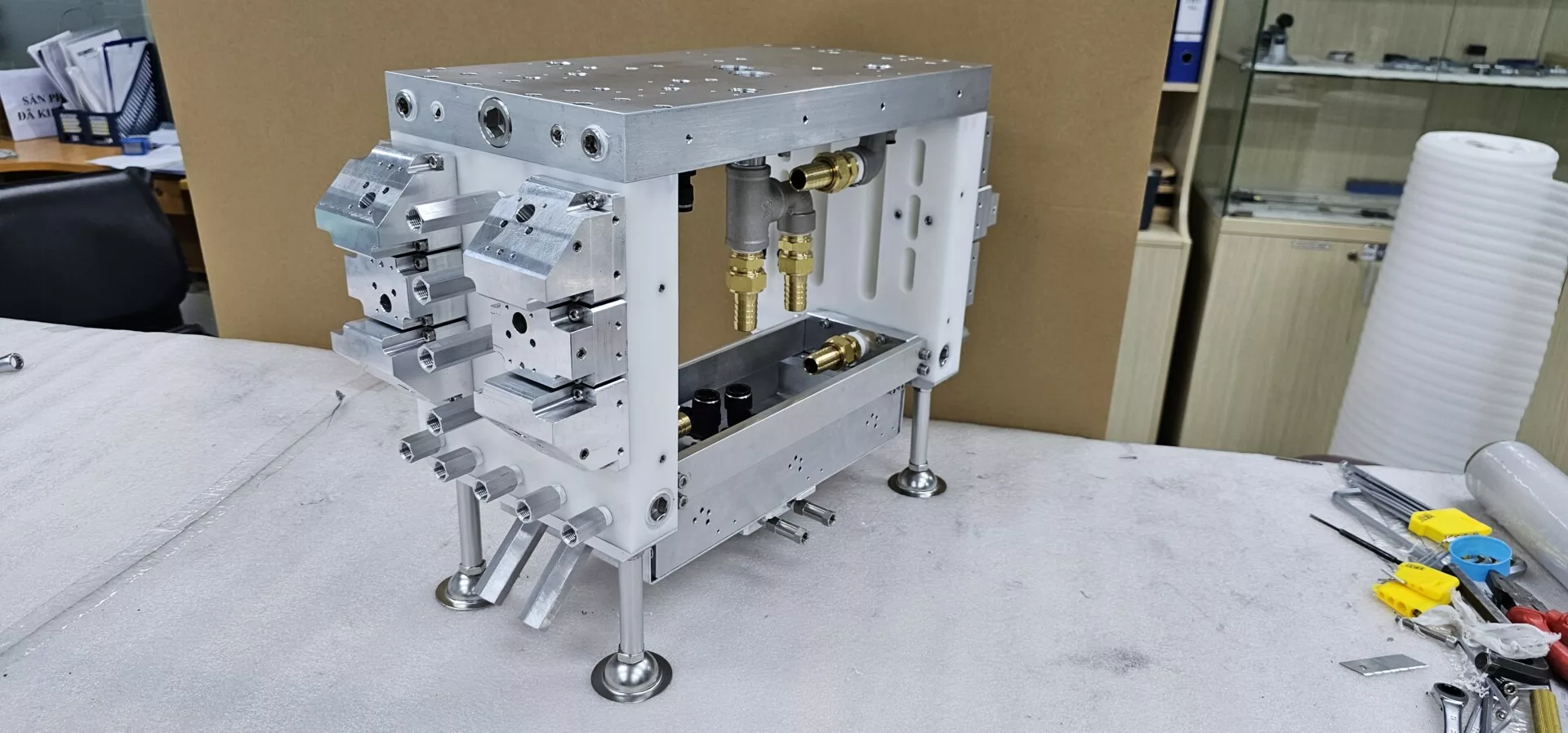

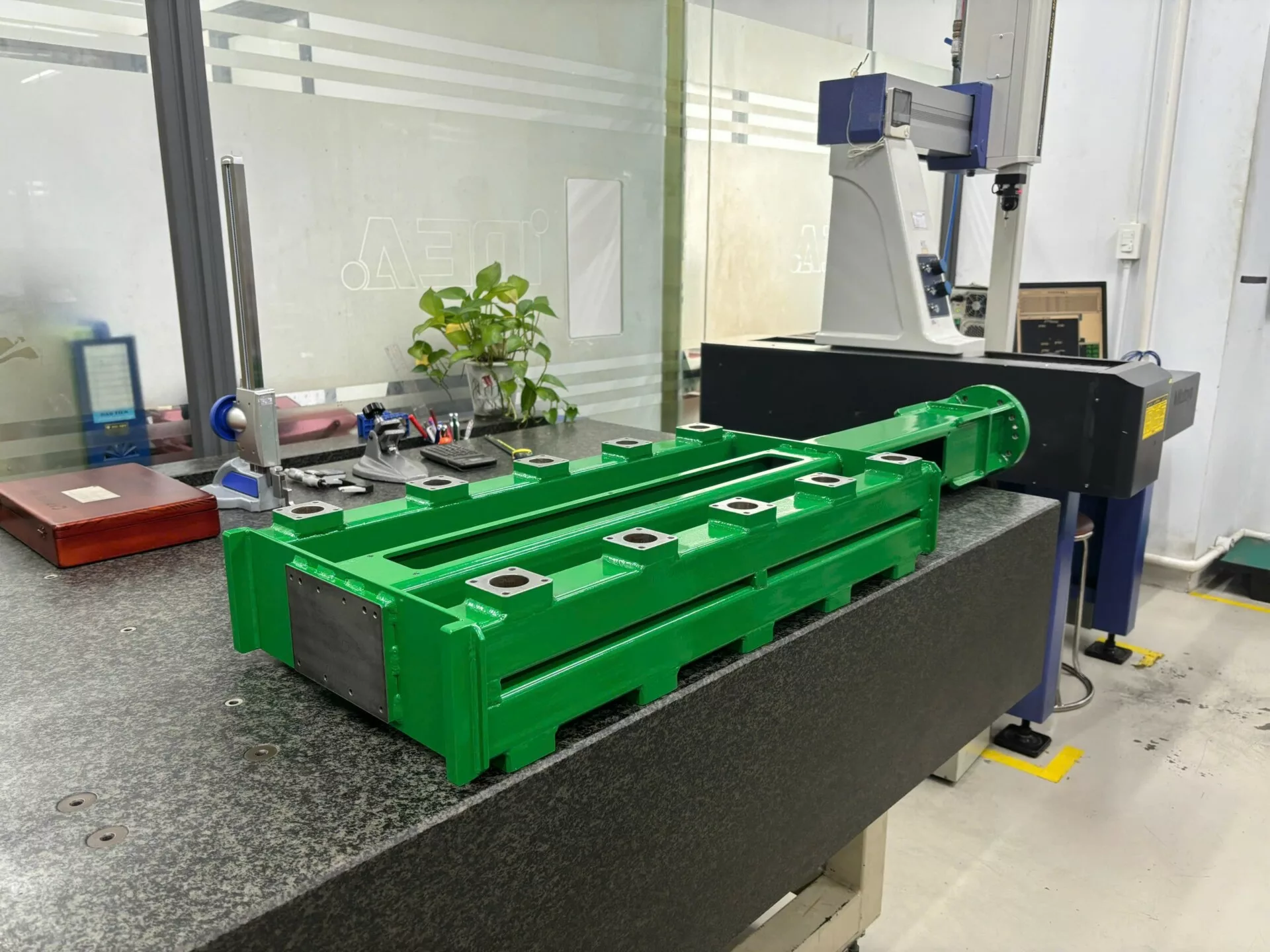

Project Overview The machined part in this project was a Runner component with 15 twisted blades, developed for a client specializing in R&D of compact turbines used in educational, experimental, and technology demonstration applications. This Runner is part of a turbine flow simulation device, requiring excellent blade uniformity, precise theoretical twist angles, and smooth surfaces […]