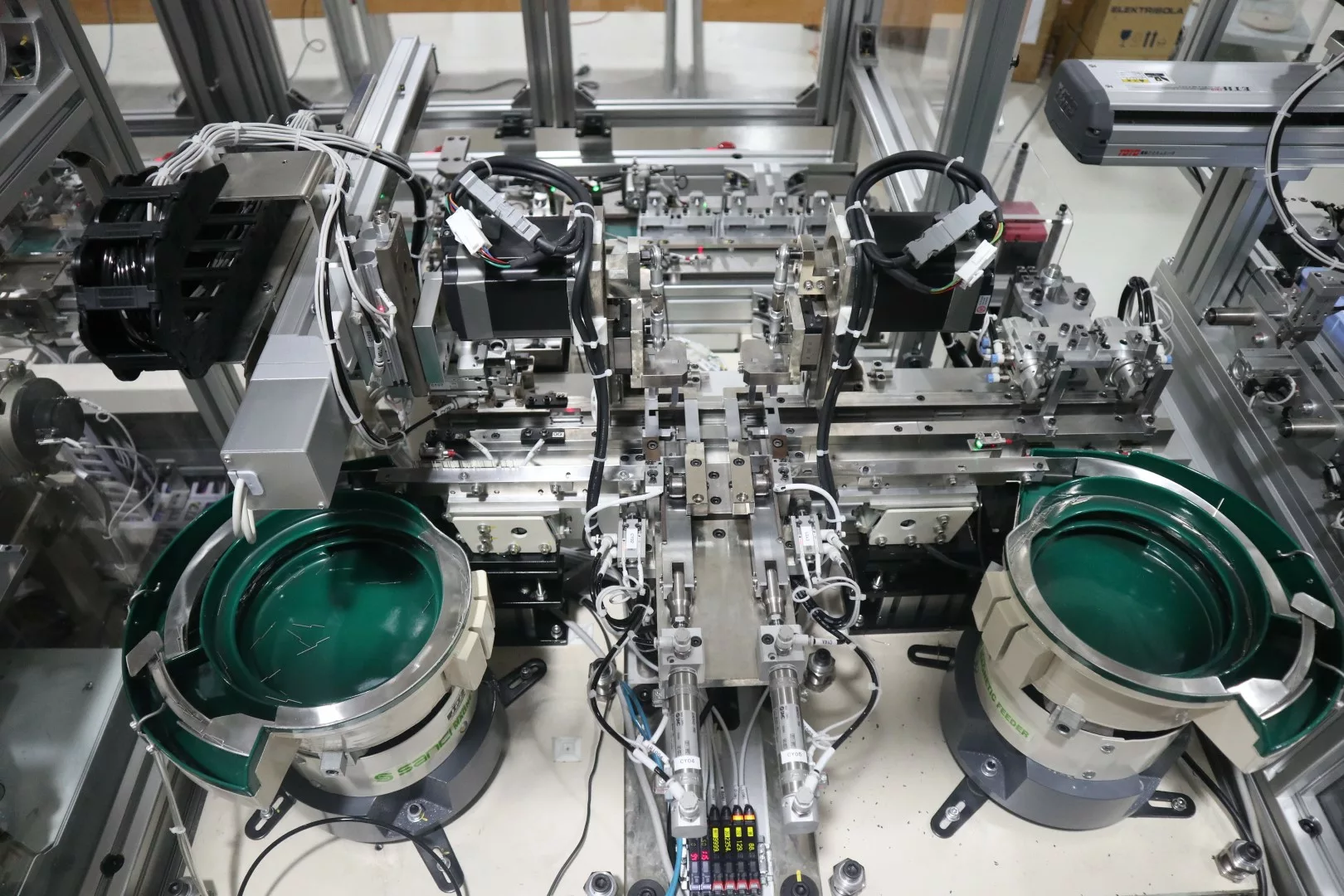

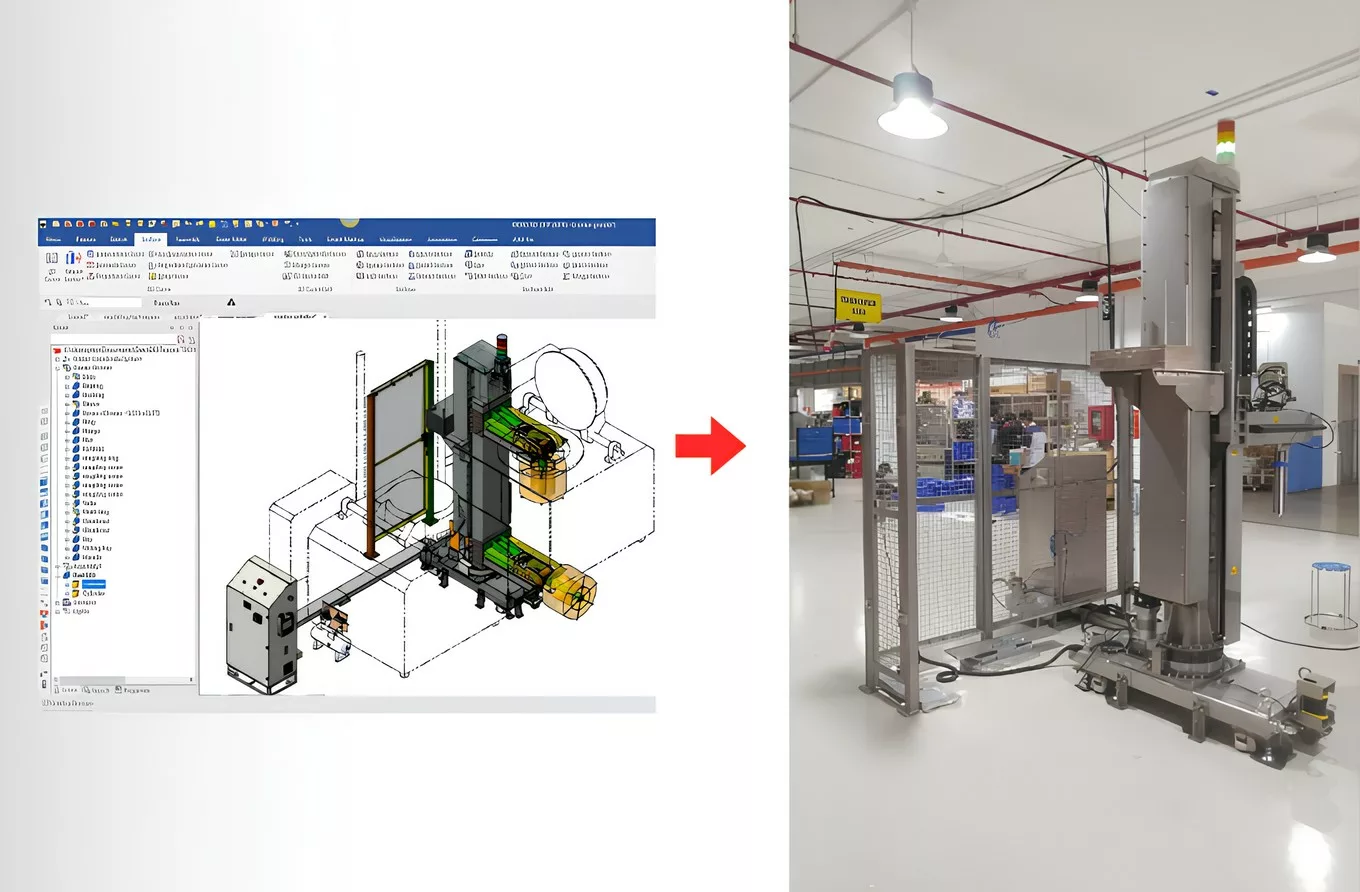

Automated Bottle Filling Solution Increases Productivity to 6000 Bottles/Hour and Ensures Quality in the Pharmaceutical Industry

The automated bottle filling solution in the pharmaceutical industry boosts productivity, ensures quality, and complies with industry safety standards. The system is designed to achieve a filling rate of 6000 bottles per hour, strictly adhering to JIS standards, and integrates seamlessly into the existing production line. As a result, productivity increased significantly without compromising product quality, further strengthening the company’s reputation for performance and reliability.