Sheet Metal Fabrication & Industrial Design

Sheet Metal Fabrication & Industrial Design

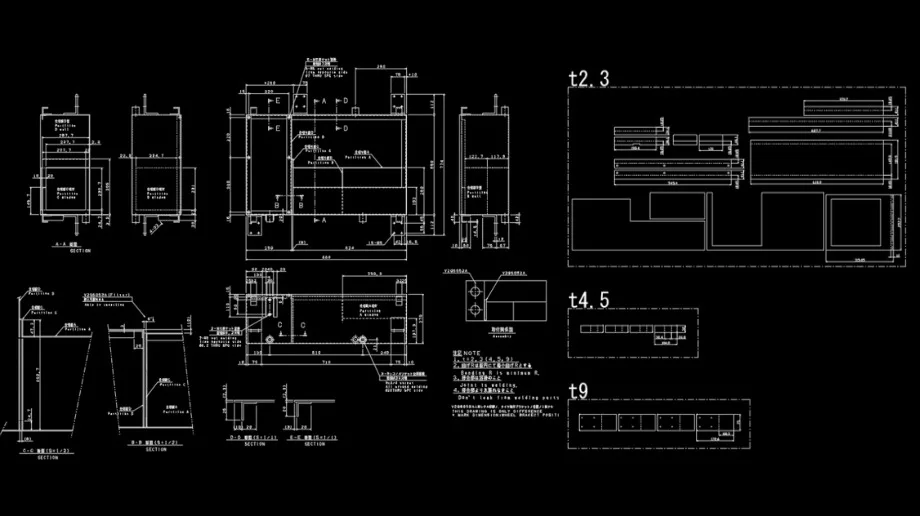

IDEA provided expert engineers and standardized workflows using Topsolid to deliver fast, accurate sheet metal drawings aligned with Japanese standards.

The client reported a 30% boost in productivity and 35% cost savings, praising IDEA’s quality, speed, and reliability.

The client, a leading company in Japan specializing in sheet metal fabrication and high-quality industrial products, was seeking a solution to improve drawing execution efficiency while reducing time pressure and costs. To meet this need, they partnered with IDEA to implement Sheet Metal Design Services using Topsolid software for accurate and efficient drawing development.

IDEA’s Sheet Metal Design Services helped the client optimize their production workflow and achieve business goals. With a highly skilled team, professional processes, and a strong commitment to quality, IDEA continues to be a trusted partner for Japanese companies in the sheet metal fabrication industry.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.