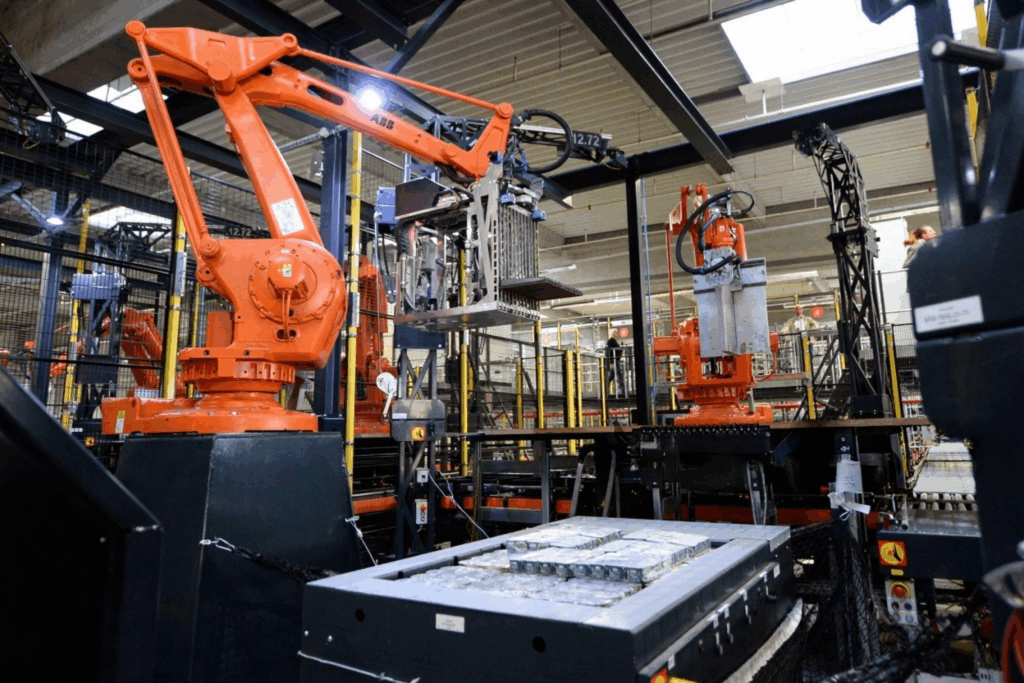

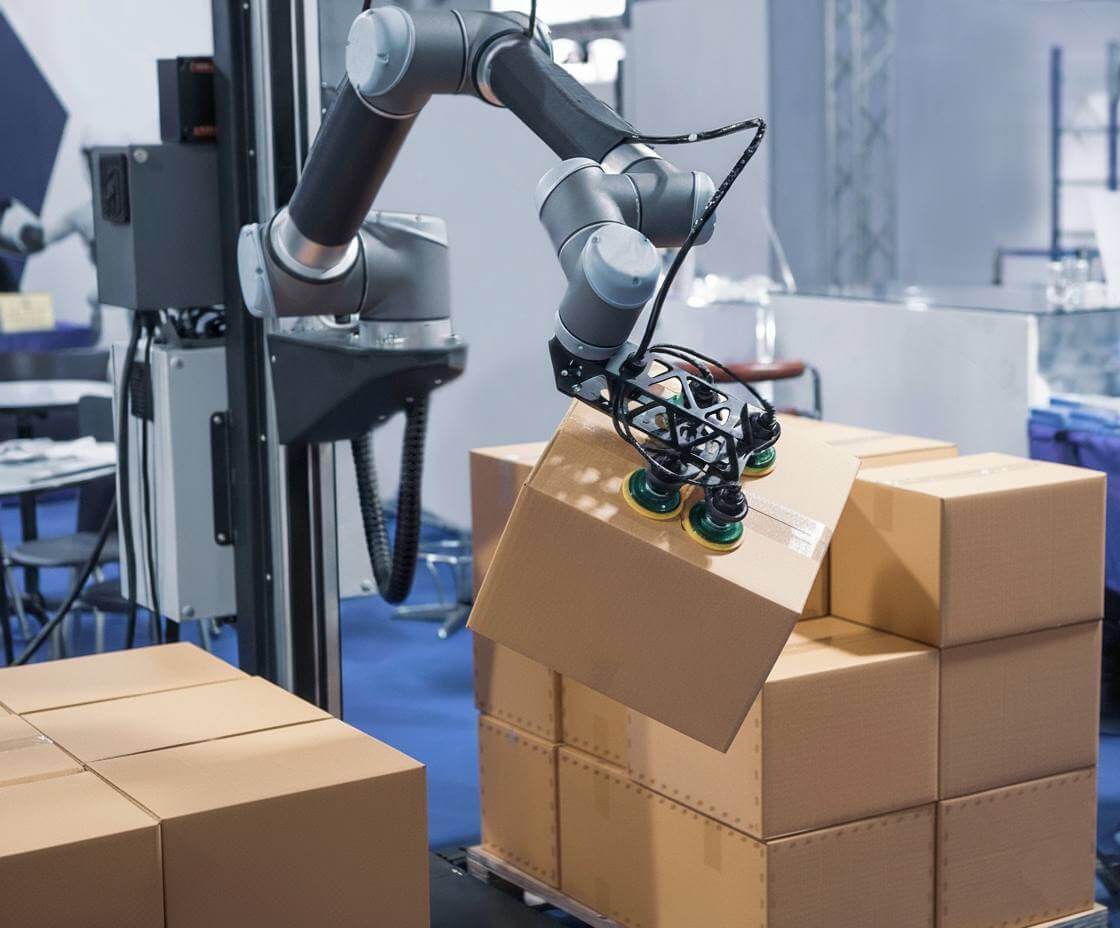

In today’s fast-growing manufacturing environment, IDEA delivers comprehensive automated palletizing solutions to help businesses maximize productivity, reduce labor costs, and ensure consistency in packaging and shipping. Our systems are designed to integrate seamlessly into existing packaging lines and adapt to multiple industries.

With over 15 years of experience in industrial automation, IDEA provides flexible robotic palletizing solutions for bags, cartons, trays, bottles, and other packaged products. Our systems ensure accurate, stable stacking while increasing throughput, reducing labor dependency, and minimizing product damage. Designed for easy integration and long-term reliability, IDEA’s palletizing solutions help manufacturers improve efficiency and delivery quality.