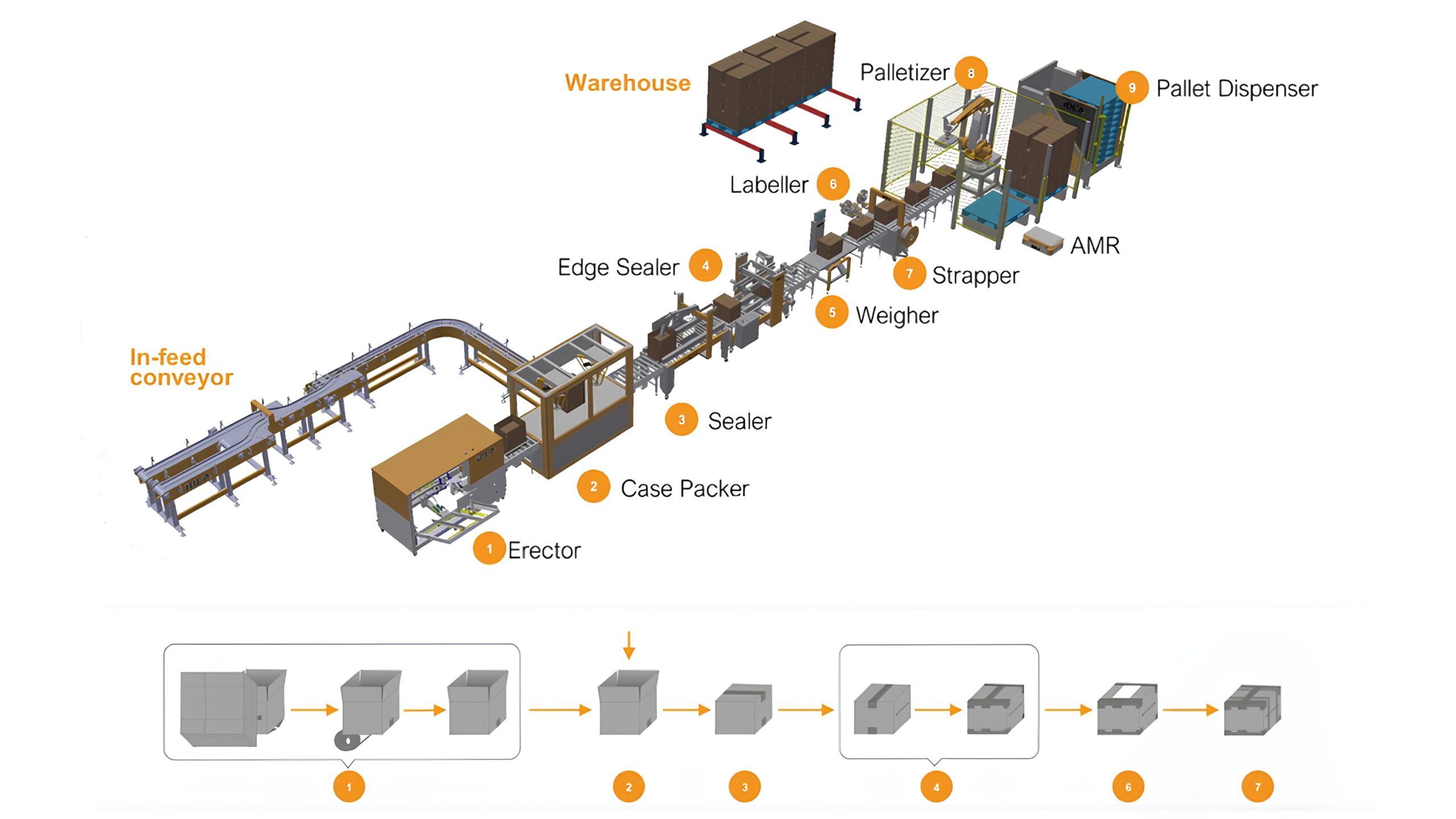

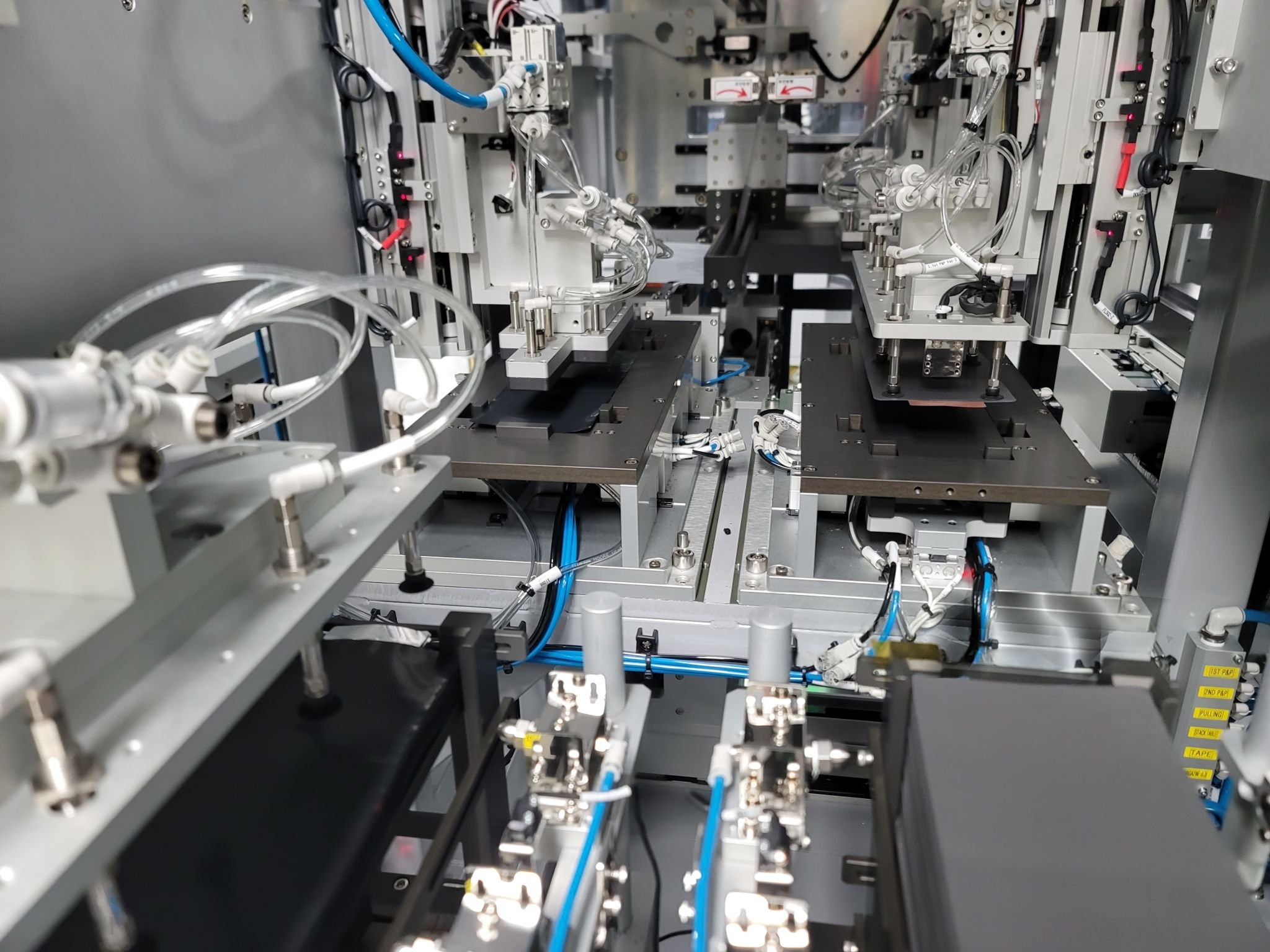

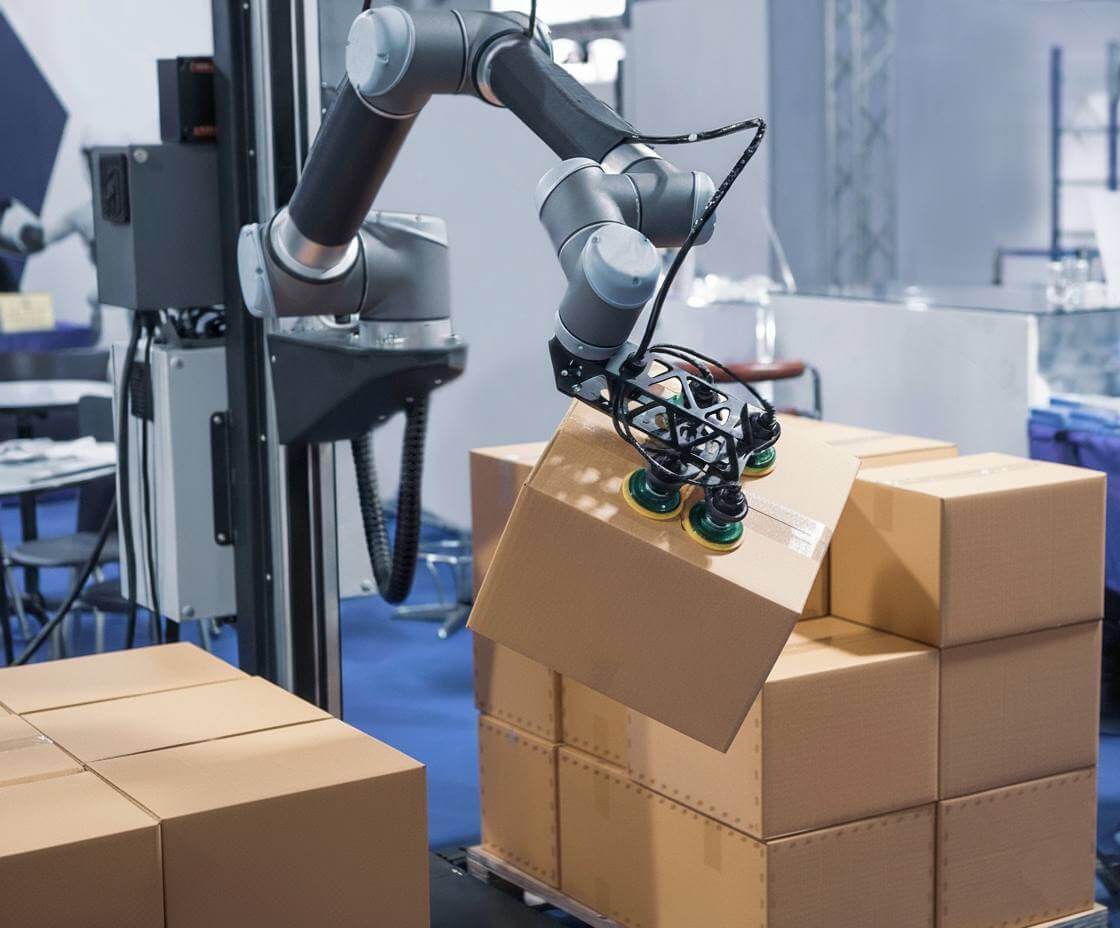

IDEA’s automated packaging solutions help manufacturers boost efficiency, cut labor costs, ensure consistent packaging quality, and enable full traceability. Our packaging line automation integrates every stage—from carton erector machine, case packer system, sealing, labeling, to palletizing solutions—into a closed-loop process, adaptable to multiple industries.