Products have unique dimensions, shapes, or technical requirements that standard machines cannot meet.

The production line needs to integrate multiple complex processes into a single piece of equipment.

LACK OF FLEXIBILITY

Existing machines cannot be adjusted for different product types.

Difficult to expand or upgrade when production demand increases.

REQUIREMENT FOR AUTOMATION AND DIGITALIZATION

Businesses want to implement industrial automation, but current equipment does not support or cannot connect existing machines to form an automated line.

Need to integrate IoT and MES for data monitoring and connectivity with production management systems.

IDEA is your strategic partner in designing and manufacturing custom machines, helping businesses overcome the limitations of standard equipment. We deliver optimized Custom Machine solutions for specialized production processes, ensuring high flexibility and scalability as your demands grow. With advanced industrial automation technology and MES integration, IDEA transforms your production line into a smart, connected, and efficient system — from concept to completion.

At IDEA, we follow a structured approach to deliver custom machine solutions that meet your exact needs. We begin with a thorough survey and requirement analysis, working closely with you to understand your production workflow, product specifications, and goals. Next, we develop a concept and preliminary design, proposing an overall solution and layout while defining the right technologies, automation level, and integration options such as robotics or IoT.

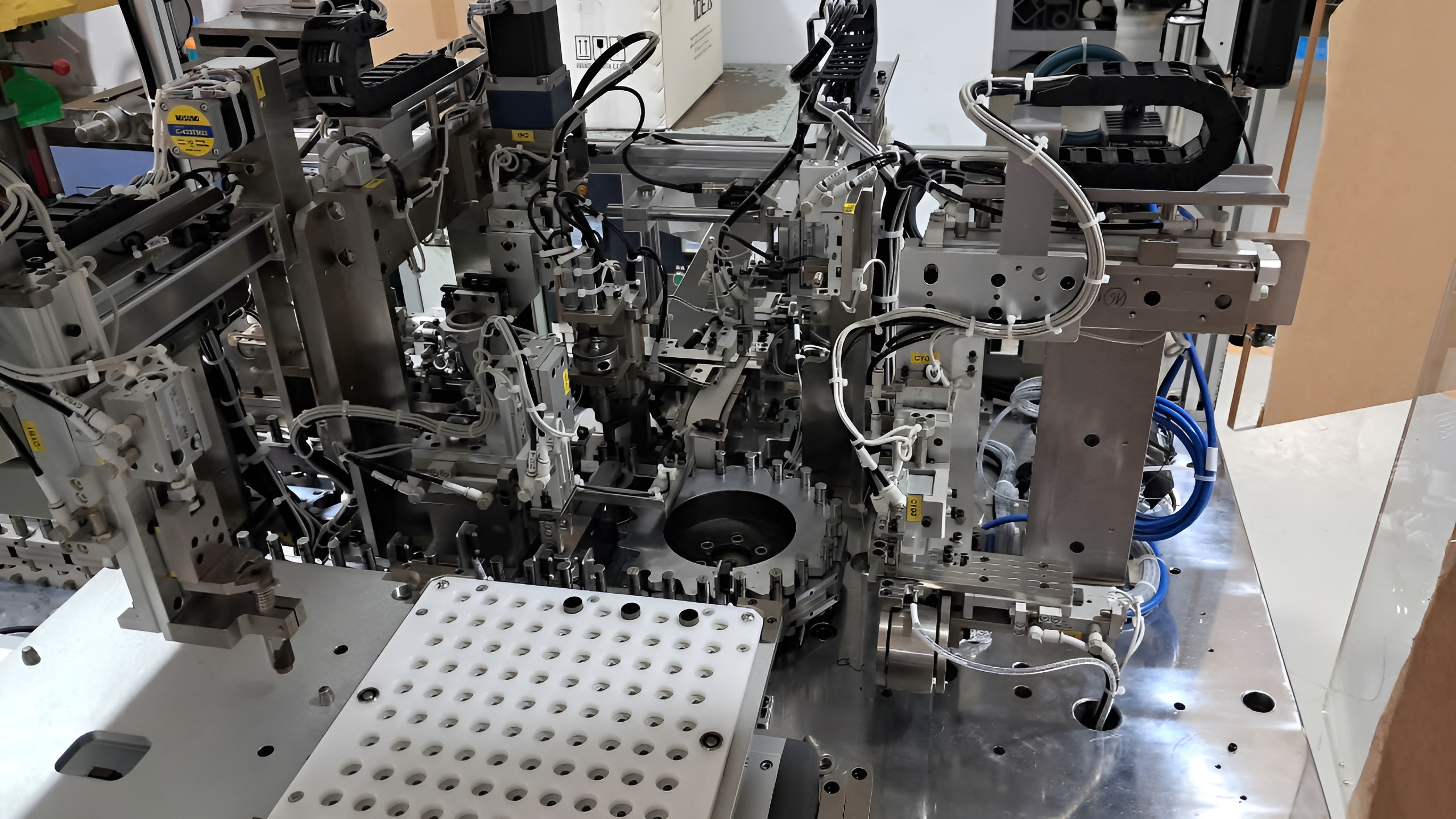

Once the concept is approved, we move to detailed design and validation, creating 3D CAD models and simulations for your review before manufacturing. Our team then handles precision machining and assembly, including mechanical fabrication, electrical setup, and PLC/HMI control integration. After assembly, we conduct rigorous testing and trial runs to ensure accuracy, speed, and compliance with safety standards.

Finally, we deliver and install the machine at your facility, providing comprehensive training for your team. Post-installation, we offer ongoing support, including scheduled maintenance, 24/7 technical assistance, and upgrade options to keep your production ahead of the curve.

Assembly Machines, Visual Inspection Machines, Functional Testing Machines, Sorting Machines, Labeling Machines, Carton Packing Machines, Extraction Machines, Feeding Machines, Pad Printing Machines

IDEA has a team of mechanical and automation engineers with over 15 years of experience in designing, manufacturing, and integrating smart production systems. We excel in CAD/CAM, PLC, HMI, IoT, and MES/SCADA integration, and have successfully delivered hundreds of projects across industries such as F&B, packaging, pharmaceuticals, electronics, and precision engineering. Every product meets ISO 9001:2015 standards and is CE and NR12 certified, ensuring safety, durability, and reliable performance. From concept and design to manufacturing and training, IDEA provides end-to-end support to help businesses maximize their investment.

Our palletizing solutions integrate with:

When manufacturing a custom machine, the following key factors should be considered:

A thorough analysis ensures stable operation, consistent quality, and future scalability of the machine.

A Custom Machine project typically includes the following phases:

Each phase follows strict engineering controls to minimize risk and ensure stable operation at production start-up.