Challenges and Transformation Trends in the Food and Beverage Industry

The food and beverage industry is undergoing rapid transformation as regulations and market demands become increasingly stringent. However, many manufacturers still face critical challenges:

- Pressure on safety and quality: Strict regulations require tight control from raw materials to finished products.

- Low efficiency and high costs: Manual or semi-automated processes cause waste, inconsistent quality, and rising labor expenses.

- Traceability requirements: Transparent systems are needed to track products across the entire supply chain.

- Lack of flexibility: Difficulty adapting packaging formats and product variations to changing consumer demands.

As a result, transitioning to an automated production line has become essential to ensure precision, speed, and sustainable growth in the industry.

IDEA – Comprehensive Solutions for the Food and Beverage Industry

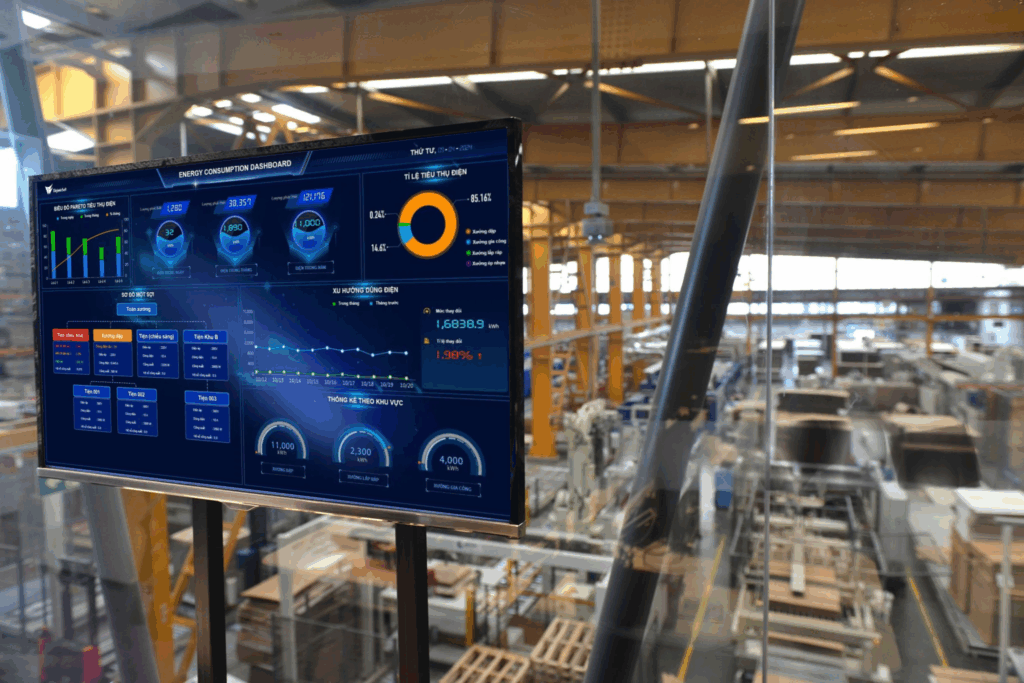

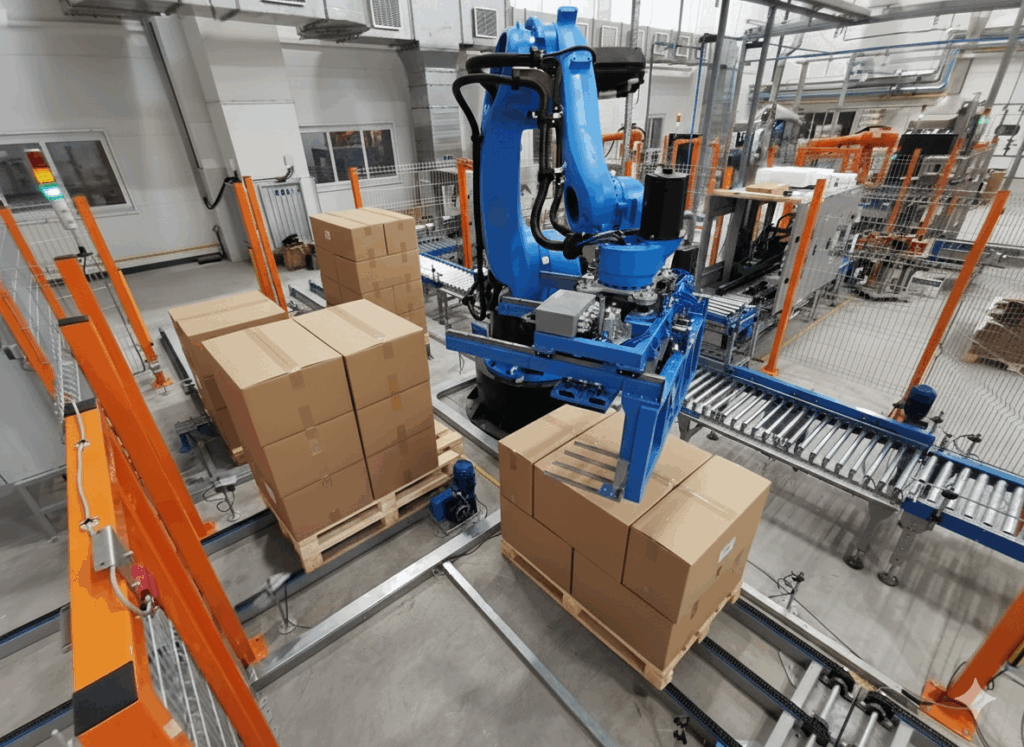

IDEA provides end-to-end automation solutions for the food and beverage industry, including custom food machinery design and fabrication, advanced inspection systems (weight checking, defect detection, label verification), and integrated automated packaging and palletizing. Our solutions are built around the automated production line, seamlessly connected with MES to manage and optimize the entire manufacturing process.

Benefits of partnering with IDEA

When working with IDEA, F&B businesses gain:

- Guaranteed Hygiene Standards: Equipment is designed and fabricated using stainless and food-safe materials, minimizing contamination risks.

- Improved Production Efficiency: Automated, synchronized systems enhance throughput and reduce operational costs with high accuracy.

- Optimized Investment Costs: IDEA adheres to the philosophy of “Quick Response – High Quality – Low Cost,” ensuring practical efficiency for businesses of all sizes.