Development and manufacturing of mechanical components for gaming machines

Development and manufacturing of mechanical components for gaming machines

“Optimized designs, more durable products with fewer defects, and significant savings in both time and development costs. IDEA is our trusted engineering partner.”

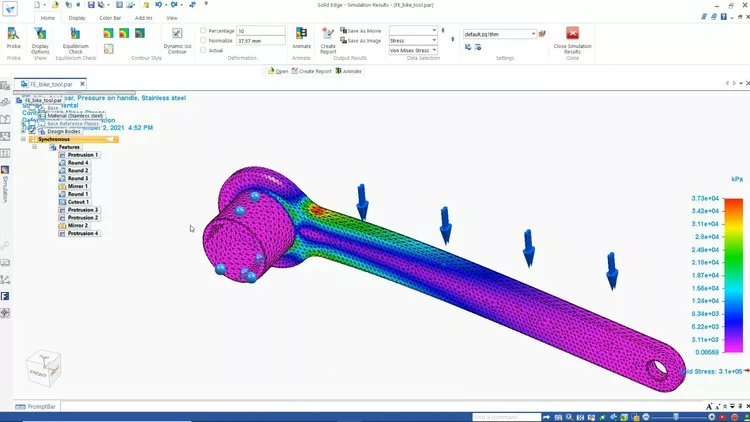

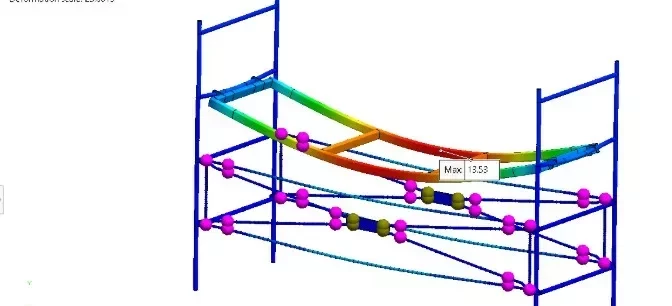

Our client, a Japanese company renowned for developing high-precision mechanical components used in gaming machines, faced increasing demands for accuracy, durability, and time-to-market. To address these challenges, they partnered with IDEA to leverage our force analysis simulation services, ensuring enhanced product reliability and cost-effective development.

IDEA’s force analysis simulation services played a pivotal role in optimizing our client’s mechanical design process. By integrating cutting-edge technology with deep knowledge of Japanese engineering standards, IDEA not only improved product quality but also reduced lead times and development costs. This project reinforces IDEA’s position as a trusted partner for high-precision mechanical design solutions.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.