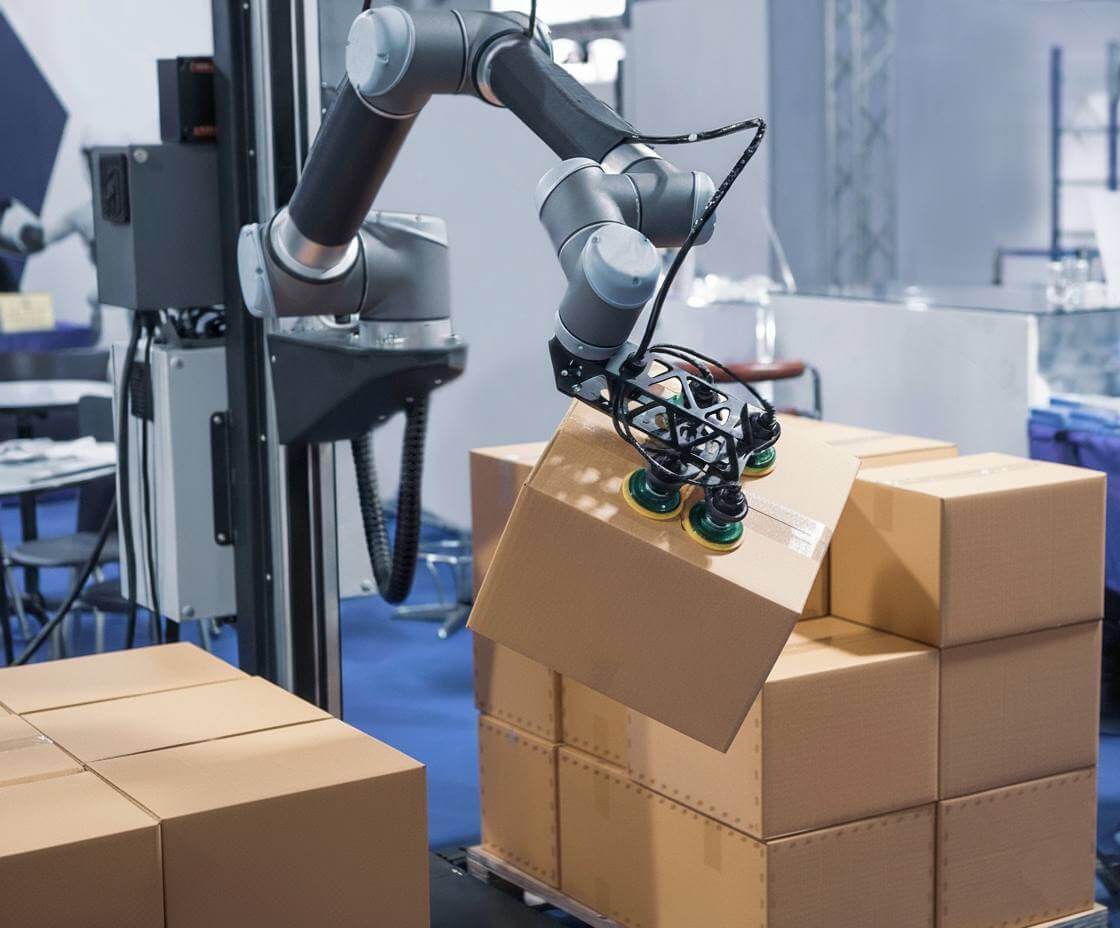

In modern factories and warehouses, smart material handling solutions play a crucial role in ensuring a continuous, accurate, and safe flow of materials. Manual or fragmented transportation not only reduces productivity but also makes control and operational optimization more challenging.

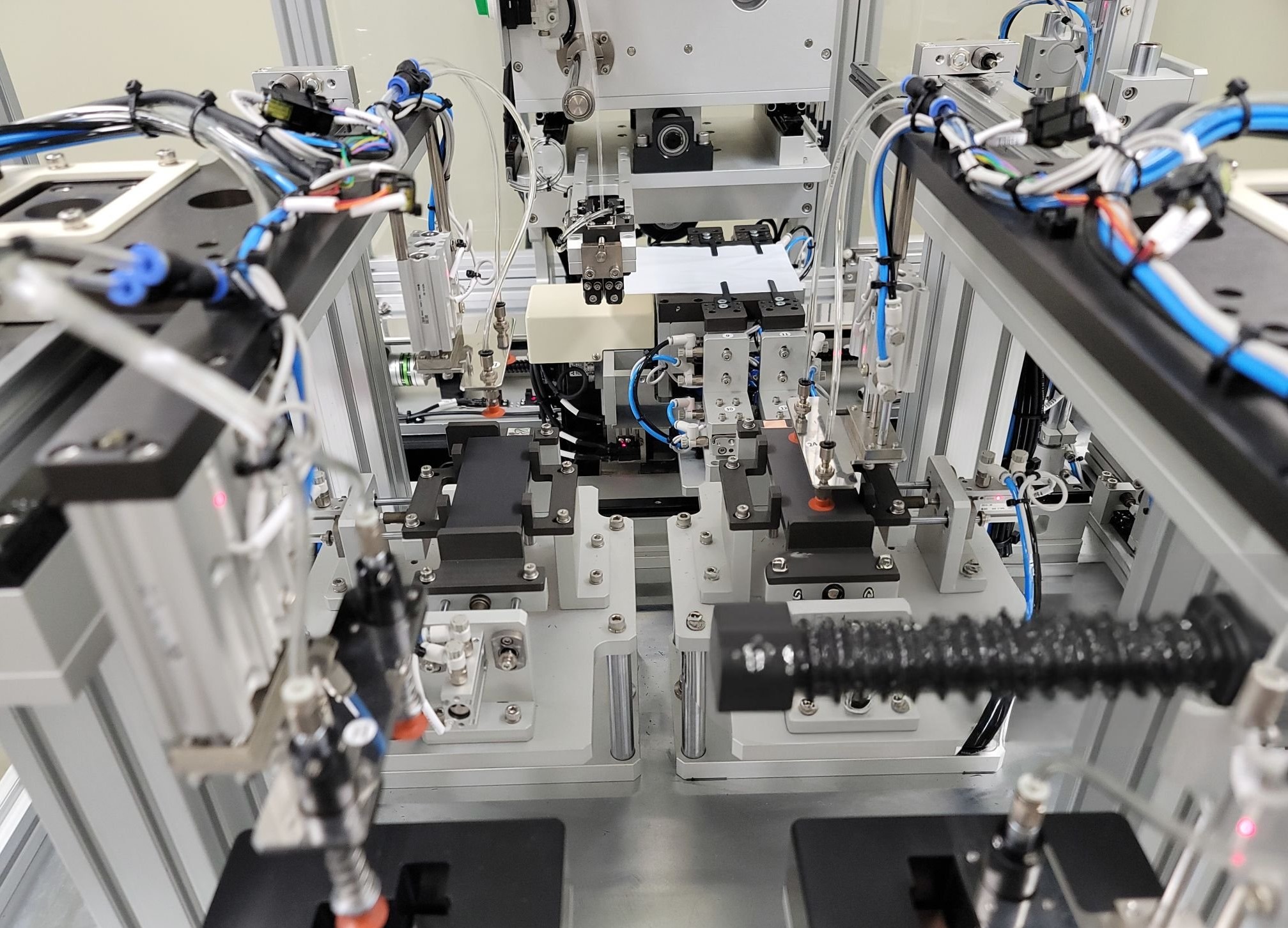

IDEA Group’s smart material handling solution is designed to fully automate internal transportation processes through the integration of conveyor systems, AGV/AMR autonomous vehicles, and a real-time MES monitoring system. This helps businesses improve operational efficiency and stay ready for future expansion.