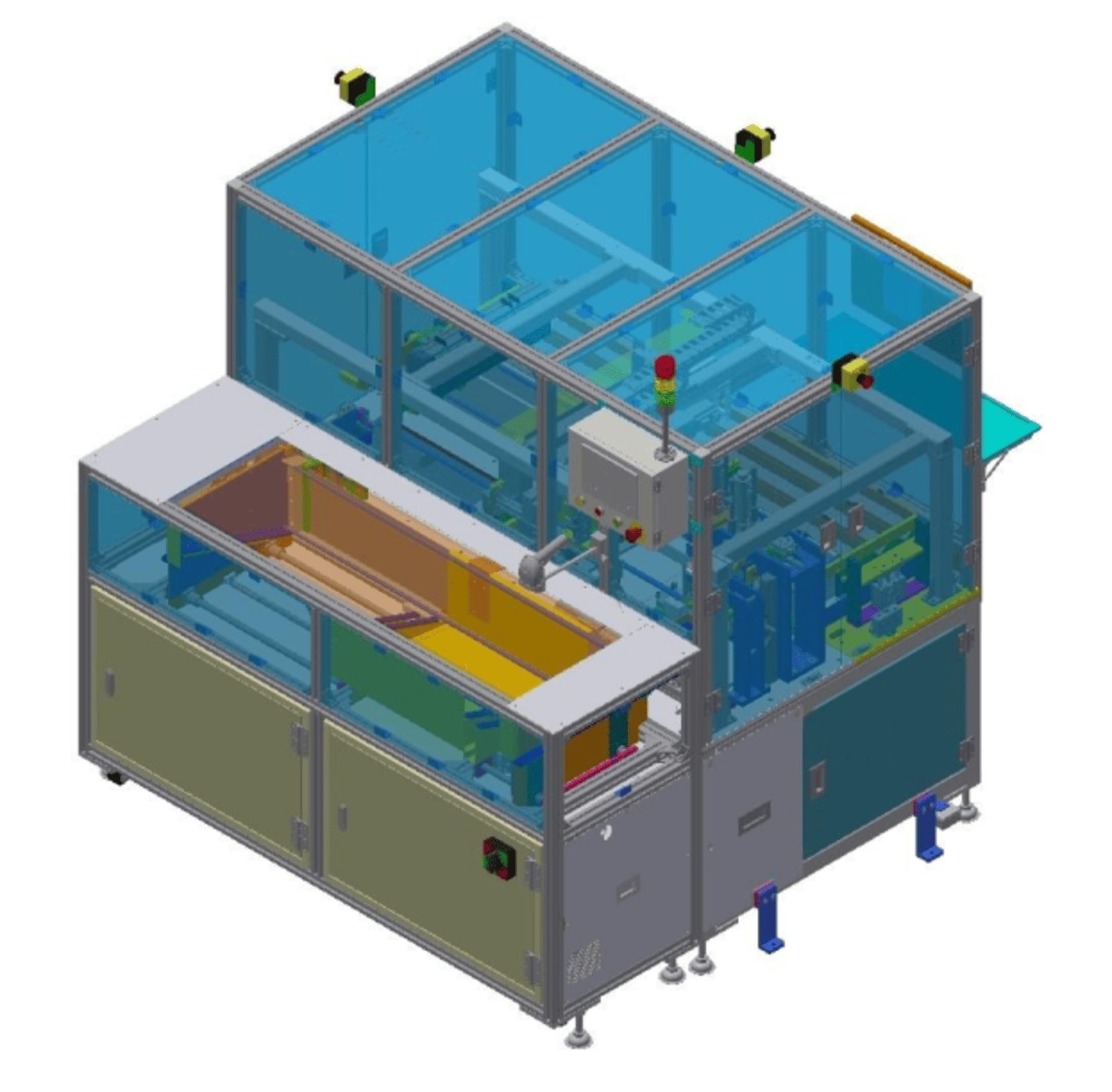

IGR-AIM-01 is an advanced automatic frequency inspection device designed for high-precision products. With a cycle time of only 10 seconds per item, this solution helps manufacturers reduce inspection time, increase productivity, and minimize labor costs and human errors compared to manual testing.

Perfect for industries requiring exceptional accuracy, such as golf club manufacturing and mechanical component production.

Upgrade your quality control process with IGR-AIM-01 – the smart choice for industrial automation and precision testing.

| Item | Details |

|---|---|

| Machine Code | ACP2309-001 |

| Project Name | Auto Frequency For QC |

| Function | Automatic inspection of product functionality by measuring run frequency |

| Cycle Time | 10 seconds per product |

| Product Dimensions | 1100 mm × 1200 mm × 1250 mm |

| Production Capacity | 2,520 products per shift |

| Main Equipment (Makers) | PLC (Mitsubishi), Servo (Delta), Inverter (Delta), Sensor (Keyence) |

| Completion Time | 3 months |