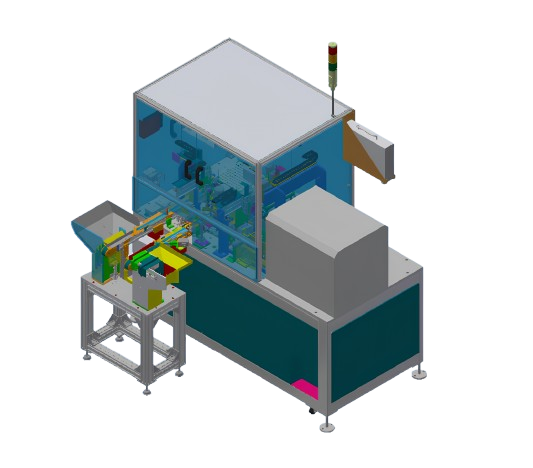

The NSVC2412-001 automated assembly and adhesive dispensing machine is designed to optimize the production process for motor components. Featuring high-quality components such as Keyence PLC, Misumi step motor, and Keyence IV2 camera, this system ensures stable and precise operation for demanding manufacturing environments. Its compact dimensions (1750 × 870 × 1400 mm) allow seamless integration into existing production lines, while its impressive capacity of 5,760 units per shift meets the needs of high-volume production. With a lead time of just three months after PO issuance, NSVC2412-001 is the ideal solution for electronics manufacturers and Japanese FDI enterprises seeking to enhance efficiency and accuracy in their assembly processes.

| Item | Details |

|---|---|

| Machine Code | NSVC2412-001 |

| Project Name | Automatic Assembly Machine for MSG-B Components |

| Function | Automated assembly of motor components and adhesive application |

| Cycle Time | 5 seconds per product |

| Product Dimensions | 1750 mm × 870 mm × 1400 mm |

| Production Capacity | 5,760 products per shift |

| Main Equipment (Makers) | PLC: Keyence Step Motor: Misumi Sensor & Camera: Keyence IV2 |

| Completion Time | 3 months (after PO issuance) |