Mechanical design optimization is a critical aspect in the development of automated machines. As automation takes center stage across manufacturing sectors, ensuring that machines are not only functional but also efficient and reliable is essential. Optimizing the mechanical design process improves operational performance, enhances durability, and reduces production costs, offering manufacturers a competitive advantage in today’s fast-paced industrial landscape.

What Is Mechanical Design Optimization?

Mechanical design optimization involves enhancing various aspects of mechanical components and systems to achieve better performance, efficiency, and cost-effectiveness. In automated machines, this process is essential for reducing downtime, increasing machine lifespan, and improving output quality.

Successful optimization incorporates engineering analysis, simulation tools, and practical experience to identify weaknesses, reduce excess material, and streamline complicated mechanical assemblies. The outcome is a robust design tailored for efficient automation.

Key Goals of Optimization in Automated Machines

- Performance Enhancement: Improve precision, speed, and consistency of machine operations.

- Reliability: Reduce wear and tear, leading to longer maintenance cycles.

- Energy Efficiency: Minimize excessive power consumption.

- Cost Reduction: Cut down on material usage without compromising strength or stability.

Core Principles of Mechanical Design for Automation

Designing for automation introduces unique challenges compared to general machine design. It requires consideration of dynamic forces, actuator selection, tolerances, and control integration. At IDEA Group, experts utilize advanced CAD modeling and FEA simulation to ensure accuracy across the mechanical design cycle.

Important design elements include:

- Precision alignment of components

- Ergonomic access for maintenance and operation

- Integration with control systems and feedback loops

- Ease of manufacturability and assembly

Tools and Technologies Used

Mechanical design optimization for automated machines relies on a suite of digital tools:

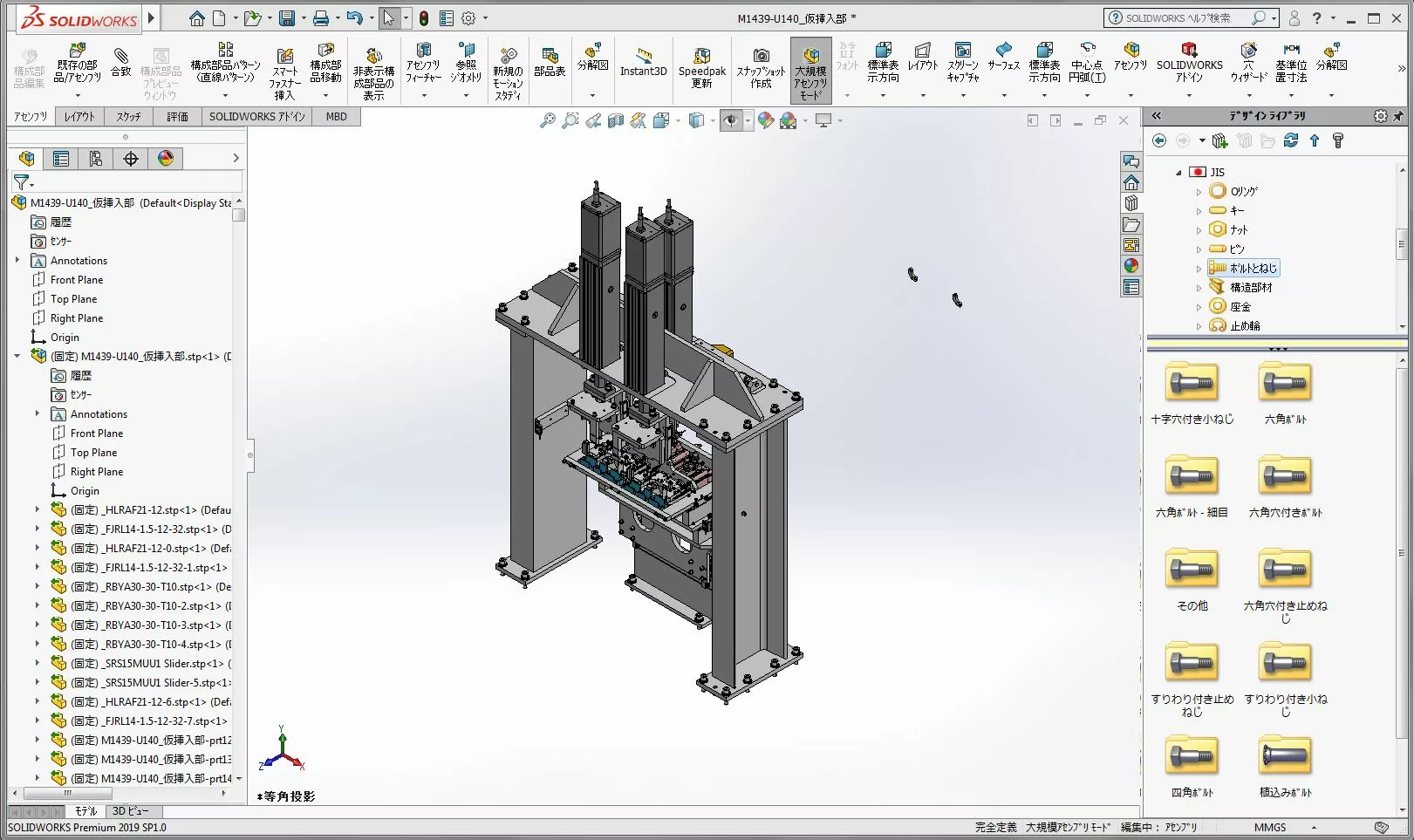

- CAD Software: 3D modeling tools to visualize and refine machinery layouts

- Finite Element Analysis (FEA): Analyze structural integrity under simulated conditions

- Motion Simulation: Evaluate dynamic movement and potential mechanical clashes

- Generative Design: AI-powered tools to propose optimal configurations

Using technologies featured on platforms like Che Tao May IDEA helps accelerate design iterations while maintaining high mechanical performance standards.

Real-World Benefits of Design Optimization

Proper optimization delivers measurable improvements in automated systems. Manufacturers can benefit from:

- Shorter production cycles

- Increased machine throughput

- Stronger design resilience to environmental factors

- Reduced machine footprint and streamlined layout

The team at IDEA’s Machine Design and Drafting Services has successfully implemented such optimized mechanical designs across multiple industrial sectors, from packaging automation to precision robotics.

Overcoming Challenges in Optimization

Despite its advantages, mechanical design optimization involves challenges like balancing performance with cost, adhering to tight timelines, and integrating new tech within legacy systems. Leveraging expert support and proven methodologies can significantly ease this transition.

Collaborating with advanced engineering providers, such as those featured on IDEA TechMart, ensures access to the latest components, design technologies, and industry standards.

Partner with Vietnam’s Leading Experts in Mechanical Design

Mechanical design optimization for automated machines plays a pivotal role in enhancing industrial efficiency, productivity, and innovation. A well-optimized system not only meets production demands but consistently exceeds expectations in real operating conditions.

Ready to bring your automation vision to life? Collaborate with IDEA — Vietnam’s trusted partner in industrial machine design and manufacturing. Our team of engineers is here to tailor scalable, cost-effective solutions that power your success in the Industry 4.0 era.