Industrial robots are transforming the landscape of machine design and automation by introducing unprecedented levels of precision, flexibility, and efficiency. As manufacturing operations evolve towards smart factories, the integration of advanced robotics has become a critical component in optimizing productivity and reducing operational costs. Companies that embrace this shift are gaining a strong competitive edge in today’s fast-paced industrial environment.

How Industrial Robots Are Reshaping Machine Design

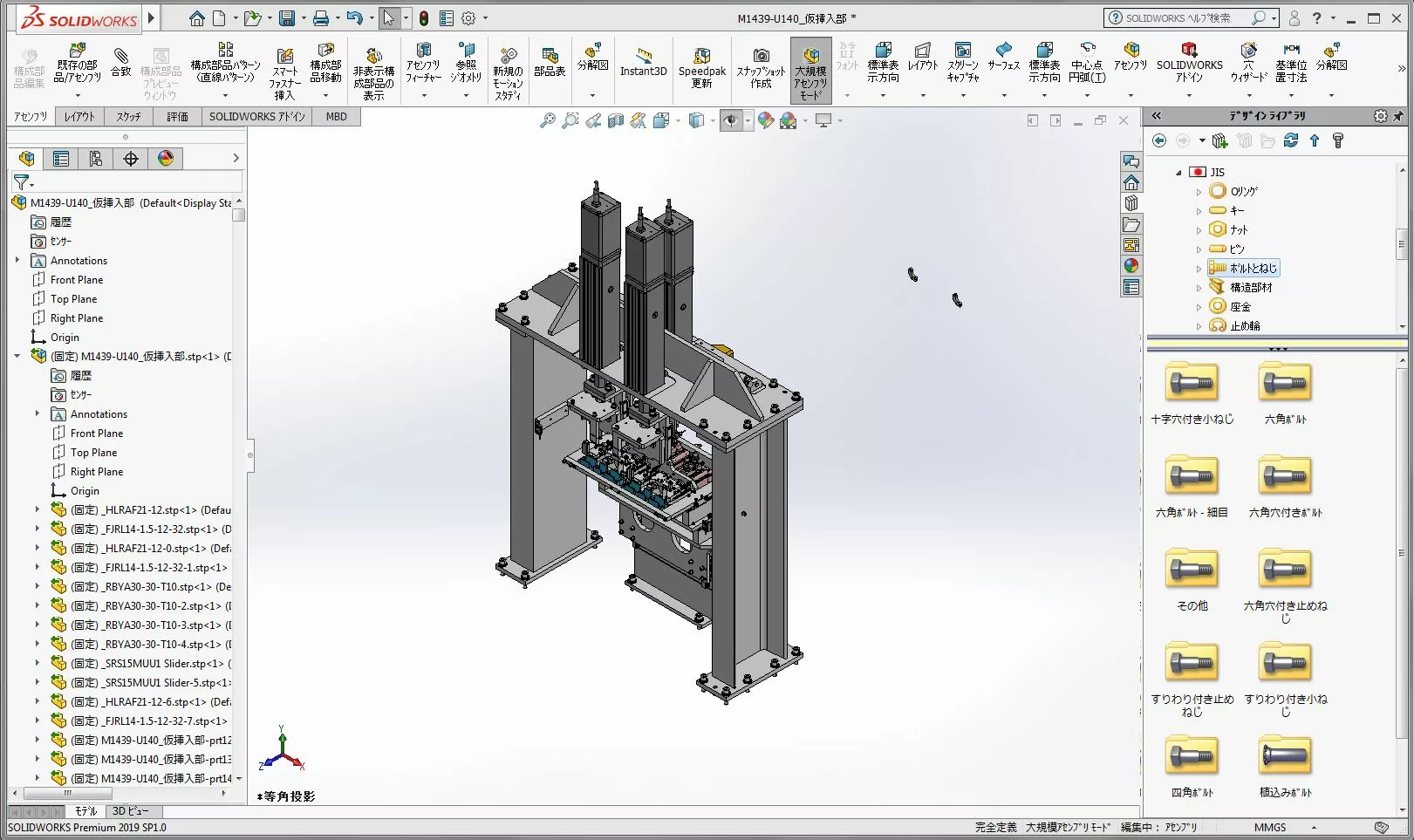

In modern machine design, industrial robots are not just auxiliary tools—they are fundamental elements of intelligent manufacturing systems. Their ability to handle repetitive, complex, or hazardous tasks allows engineers to innovate smarter and safer machines that deliver consistent performance.

Key improvements robots bring to machine design include:

- Enhanced Customization: Robotics systems can be adapted to suit specific workflows and product requirements.

- Greater Design Flexibility: Robots enable modular systems that can evolve with production needs.

- Integrated Smart Sensors: These allow machines to react in real-time to external conditions.

Critical Role of Automation in Advanced Manufacturing

Today’s factories rely heavily on smart automation to boost throughput while maintaining tight quality control. When combined with industrial robots, automation accelerates production cycles by streamlining material handling, quality inspection, assembly, and packaging.

Seamless robot integration enables:

- Reduced human error in critical processes

- 24/7 production capabilities with minimal downtime

- Data-driven insights for proactive maintenance and performance optimization

Smart Machine Design Principles Empowered by Robotics

The foundation of intelligent machine design hinges on precision engineering, digital modeling, and system integration. With the inclusion of industrial robots, these principles are elevated to a new level of agility and performance. Proper planning in the design phase ensures that automation components enhance total machine value, not just functionality.

Visit our Machine Design and Drafting Services page to learn how IDEA applies these principles in real projects across Vietnam.

Applications of Robots in Smart Factory Environments

Industrial robots are being deployed in diverse roles across industries such as automotive manufacturing, electronics, and food processing. They work alongside human operators in collaborative setups, handle high-precision tasks in cleanroom settings, and even assist in real-time product customization.

Our partner Che Tao May IDEA showcases real-world applications where robotics have significantly enhanced operational efficiency and output quality.

Benefits of Integrating Industrial Robots into Your Automation Strategy

Implementing robotics in machine design doesn’t just modernize production—it unlocks long-term benefits for scalability and innovation. Companies serious about growth are investing more in automation to meet the demands of a changing market.

Major advantages include:

- Improved Throughput: Faster production rates with less downtime

- Enhanced Safety: Robots take over risky tasks, reducing workplace incidents

- Cost Efficiency: Reduced labor costs and waste materials in the production process

Explore automation technologies available through IDEA Tech Mart—your one-stop shop for industrial automation components and solutions.

Partner with a Leader in Machine Design and Automation

As a trusted name in Vietnam’s industrial sector, IDEA Group brings advanced expertise in integrating industrial robots into custom machine designs. Our team takes a holistic approach, ensuring seamless automation that aligns with your production goals. Whether you’re upgrading an existing system or building a new smart factory from scratch, we have the tools and talent to deliver results.

The future of industrial automation is already here—connect with IDEA today to revolutionize your operations through intelligent machine design and cutting-edge robotics.