In today’s rapidly evolving manufacturing environment, smart machine design and industrial automation are redefining how industries operate, compete, and grow. As companies embrace Industry 4.0, integrating intelligent machines with autonomous systems and digital networks has become essential for optimizing efficiency, precision, and sustainability in production processes.

What is Smart Machine Design?

Smart machine design involves the creation of machines embedded with sensors, control systems, and intelligent technologies that allow real-time data collection, analysis, and autonomous decision-making. These machines are engineered for adaptability and scalability, ensuring that businesses remain agile in the face of shifting market demands.

Key components of smart machine design include:

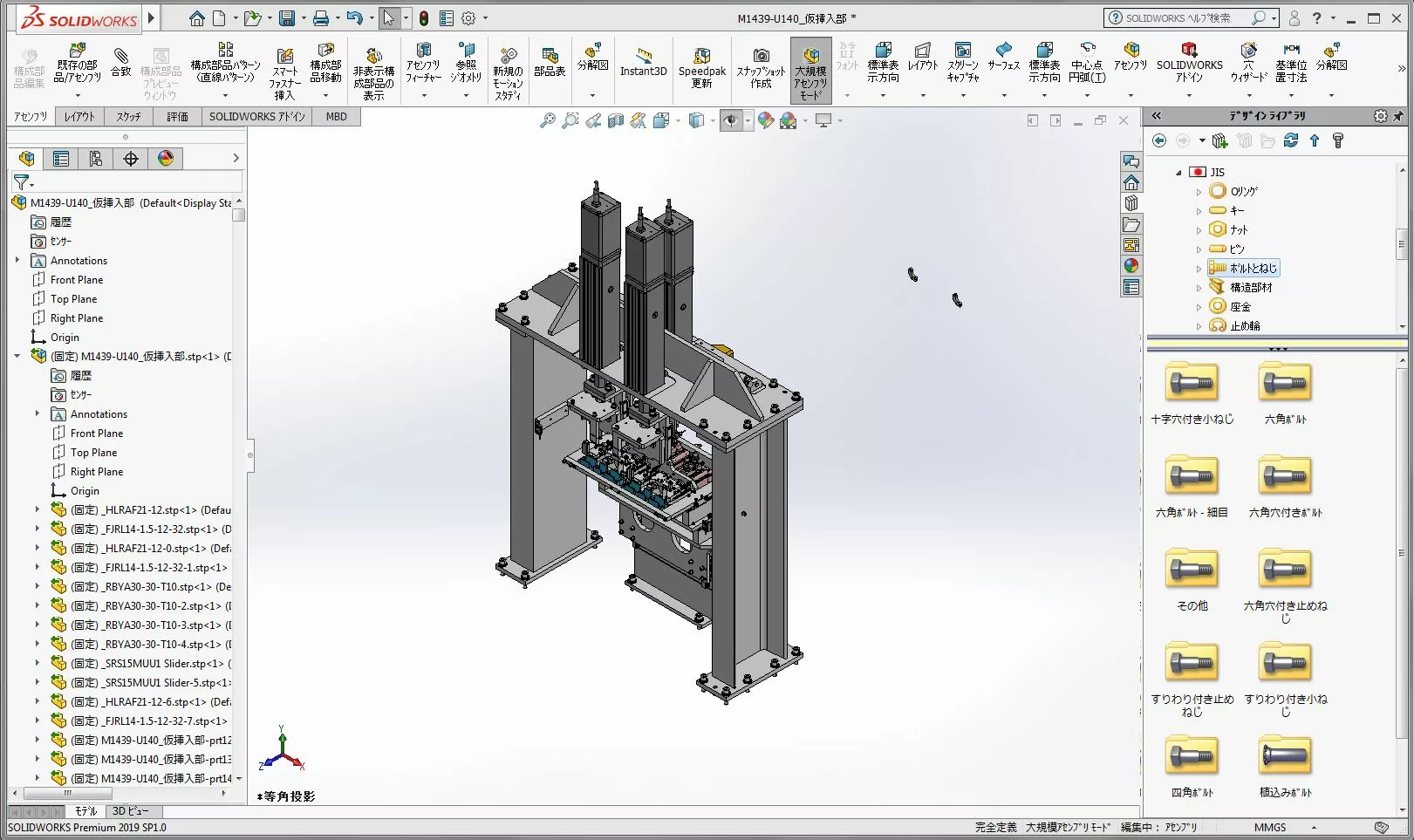

- Advanced CAD modeling and simulation for optimized functionality

- Integration of IoT and sensor technologies for real-time monitoring

- Programmable logic controllers (PLCs) for automated operations

- Artificial intelligence (AI) and machine learning algorithms for predictive maintenance and performance optimization

The Role of Industrial Automation in Modern Manufacturing

Industrial automation uses control systems—like robots, software, and electronics—to perform processes with minimal human intervention. When combined with smart machine design, automation not only increases productivity but also ensures higher quality, enhanced safety, and lower operational costs.

Some benefits of industrial automation include:

- Enhanced production speed with reduced downtime

- Repeatable precision and product consistency

- Improved safety by minimizing human exposure to hazardous environments

- Streamlined data handling leading to more informed decision-making

With cutting-edge projects in automation and machine design, modern manufacturers are pushing the boundaries of what’s possible in industrial performance.

Industry 4.0: The Future of Smart Manufacturing

Industry 4.0 represents the digital transformation of manufacturing through interconnected systems and intelligent automation. It seamlessly connects machines, processes, and people through cyber-physical systems that communicate and operate autonomously across a digital ecosystem.

Core technologies driving Industry 4.0 include:

- Industrial Internet of Things (IIoT)

- Big Data and real-time analytics

- Cloud computing

- Digital twins and virtual commissioning

- Cybersecurity for industrial networks

By integrating these technologies, companies can achieve a smart factory environment capable of self-optimizing production, reducing waste, and responding virtually in real-time to changes in customer demand or supply chain variables.

How IDEA Group Leads in Smart Machine Design

IDEA Group is at the forefront of delivering smart machine design and automation solutions tailored to the industrial sector. Leveraging advanced design tools, a team of skilled engineers, and extensive industry experience, IDEA specializes in customized, efficient automation systems that align with Industry 4.0 standards.

Our machine design and drafting services offer end-to-end support—from concept development to 3D modeling to final implementation. This ensures quality, cost-effectiveness, and shorter time-to-market for our industrial clients.

In addition, IDEA partners with leading platforms like IDEA Techmart to continuously innovate and deliver new automation technologies relevant to Vietnam’s growing industrial base.

The Power of Integration: Smart Machines, Automation & Industry 4.0

The synergy between smart machine design, industrial automation, and Industry 4.0 creates a powerful manufacturing ecosystem that improves operational agility and enables predictive and adaptive capabilities. With smart machines seamlessly integrated into automated networks, businesses gain a significant edge in global competitiveness.

IDEA empowers manufacturers to embrace this transformation with robust, reliable, and intelligent machines designed for long-term success.

Ready to revolutionize your production process with smart machine design and industrial automation aligned with Industry 4.0? Contact IDEA—Vietnam’s trusted partner in industrial innovation—to begin your journey toward smarter, more efficient manufacturing systems.