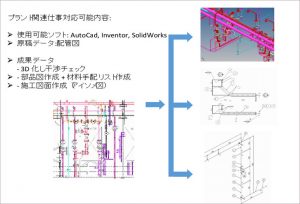

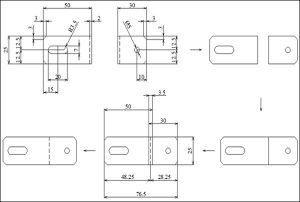

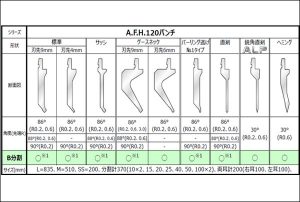

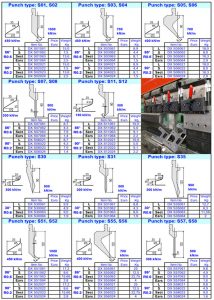

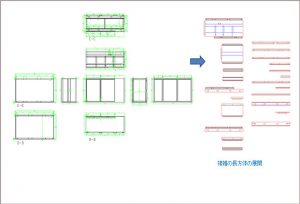

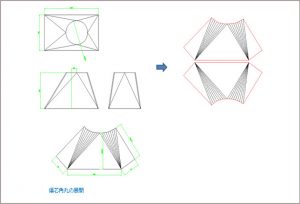

We are entrusted with creating CAD data, sheet metal data, transfering .dxf files to cilents for CNC sheet metal processing, laser cutting, plasma, bending and bending processing.

We can handle parts with complex shapes such as barrel, complex funnel, duct, chute, elbow, multi-branch, round corner, rectangular tube, pyramid, etc.

Our team has 15 technicians, supporting 12 Japanese clients.

They are young and enthusiastic. There are always a certain number of employees from other departments for backup. Such as the machine design department can assist when needed.

We can proficiently use Autocad, Solidworks, MetaCam…We can also learn and use other software provided by the clients.

Regarding the delivery term, we guarantee short-term delivery as your requirements. In particular, we are able to respond to same-day delivery and send data every hour to the clients.

Quality standards

We develop a high-standard training program to provide professional and quality products. Usually, sheet metal has a high NG rate, high risk because after we send the file, the clients can start mass production immediately. So we will put a lot of emphasis on size and implementation content checking before sending the final file. The difficult drawings will be checked 2 times or by 2 employees. So our NG rate is very low and we gained clients’ trust.

In addition, we can design many systems in the factory such as pipes, furnace systems, beam frames, working floors and other related systems.

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

| sheet metal data creation | |

|  |

|  |

|  |