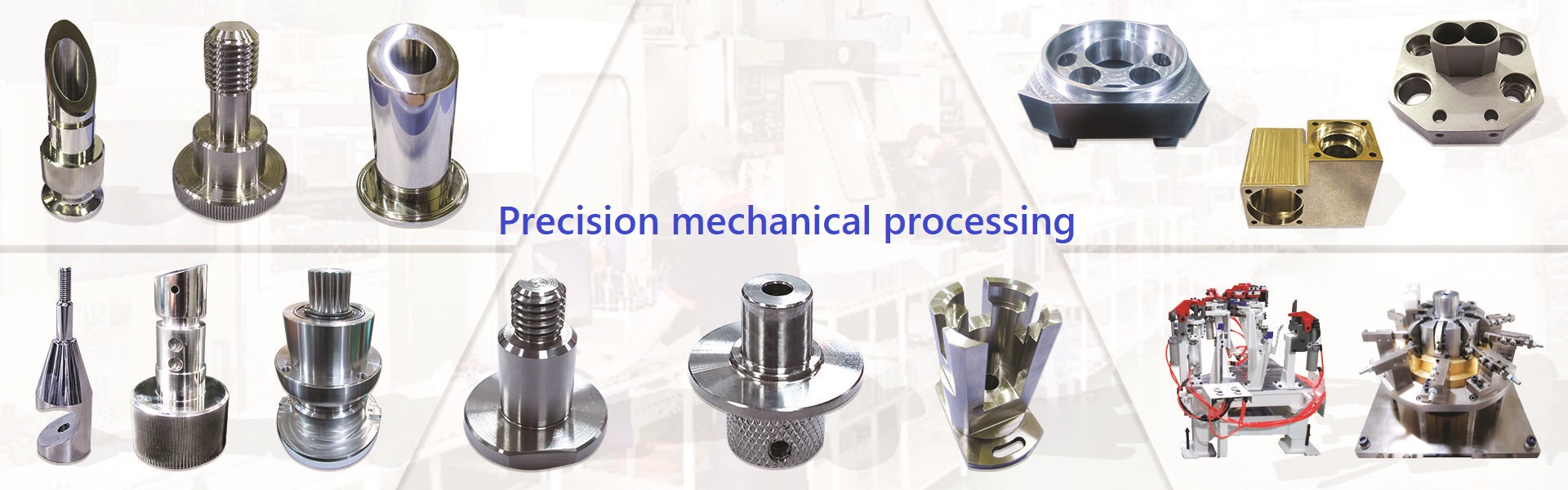

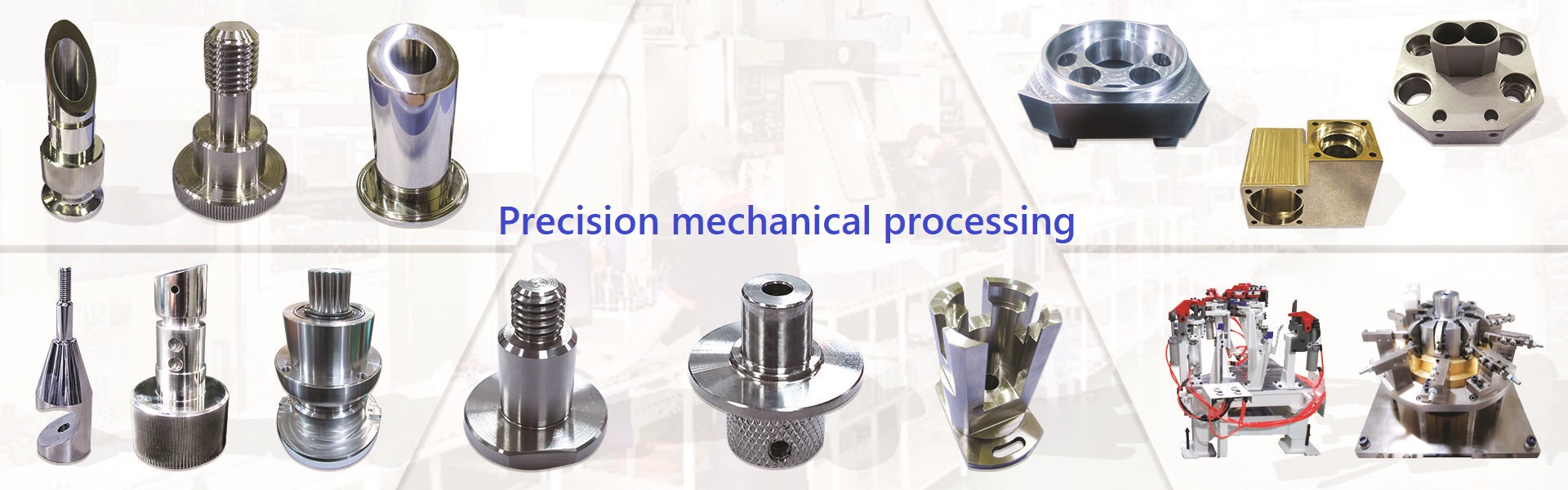

Precision mechanical processing has many outstanding advantages when using modern machines to create mechanical products that meet the requirements of high precision and increase productivity greatly.

In recent years, Vietnam has attracted attention from Japanese companies. Many foreign investors have been looking for supplies from Vietnam. However, the number of Vietnamese companies that can meet Japanese quality standards is very limited, despite a recent upward trend.

Therefore, we have acted as a bridge between Japanese and Vietnamese companies. In 2012, we formed the joint venture VIJA, which is a mechanical processing factory and built a network to satisfy our clients and partners with experienced management team, engineers and technicians.

Starting with a small factory of 500m2, however, with high efforts, the factory has been expanded to 3500m2 with more than 120 processing machines, the number of employees is increased to 162. We not only process cutting by milling machine (CNC, NC), lathe but also can weld large beam frame and have sheet metal processing workshop.

In order to better the requirements of the clients, in 2017, we established an additional 600m2 ITMC factory, a company specializing in manufacturing machines for Japan, the US and FDI companies.

Main business partners

55% machine parts produced are exported to the US and Japan.

The rest are for assembling automation machines and industrial production machines.

Our clients are in car, aerospace, semiconductor, electronics and other industrial fields.

There are 27 clients in total, including Japanese companies and American companies.

Prices

Prices are about 10 to 30% lower than those in Japan and the US.

Attractive prices in the US and Japan markets. However, they depend on the complexity of the product, quantity and delivery time.

Transportation

In case of using ship, the shipping rate is low but it may take about 2 weeks. In case of plane, it takes 3 days.

Also, the shipping rates vary depending on weight, so please contact us for details. Reference price is about 4.5 USD for 100kg package.

Materials

It is possible to purchase SS materials, SUS materials, AL materials, copper, brass and plastic materials manufactured in Japan, Taiwan, Korea or India. Unavailable materials will be imported from abroad.

Surface treatment

Chromate, blackening, anodize, zinc plate, silver plate, nickel, electrolytic nickel are used by Vietnamese, Korean, Taiwanese or Japanese companies. We are capable of spray coating, powder coating.

Heat treatment

Quenching, tempering, annealing, vacuum, carburizing, induction hardening, etc. are available.

Appropriate method will be discussed and advised.

QA Quality Control Department is focused on investing, carefully checking the quality of the drawings, the size and the appearance of the products, packages before shipment.

Production sample :

| CNC Lathe cutting product | |

|  |

| CNC Lathe cutting product | |

|  |

| CNC Lathe cutting product | |

|  |

| CNC Lathe cutting product | |

|  |

| CNC Lathe milling product | |

| CNC Milling products | |

|  |

| CNC Milling products | |

|  |

| CNC Milling products | |

|  |

| CNC Milling products | |

|  |

| CNC Lathe milling product | |

|  |

| CNC Lathe milling product | |

|  |

| CNC Lathe milling product | |

|  |

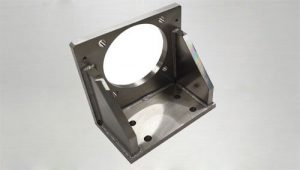

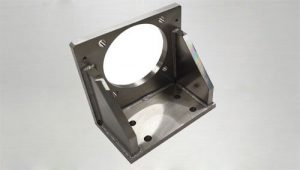

Welded parts | |

|  |

| Welded parts | |

|  |

| Welded parts | |

|  |

| Welded parts | |

|  |

| Welded parts | |

|  |

| Welded parts | |

|  |

Jigs production | |

|  |

| Jigs production | |

|  |

| Jigs production | |

|  |

|  |

| Factory photo | |

|  |

| Inspection equipment | |

|  |

| Joint venture factory | |