Ren is a word with many meanings. Thread in mechanical processing is one of the basic concepts that learners and mechanics need to understand.

So what is ren?

Contents

1. Concept of thread in mechanics, metal

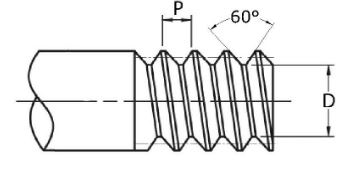

As you can see, on the cylindrical axis of the bolt, the nut (ecu) often has spirals that rotate. if there is a plane that belongs to the meridian plane of some rotating circle, this plane moving in the spiral direction will form a spiral surface and this is called a Thread.

So what is ren used for?

Threads are used to connect, transmit forces or be used to assemble mechanical machine parts together.

2. Thread classification

Threads are classified according to their construction. Common names for these types of laces include:

Cylindrical thread: Thread type formed on the surface of a rotating cylinder

Conical Thread (taper thread): The type of thread that is formed on the surface of a rotating circular cone

External Thread: Thread that is formed on the outer surface of the rotating face

Internal thread (thread hole): The type of thread that is formed on the inside of a rotating roller

For example: Ecu (nut) is a material with an internal thread, bulong is a material with an external thread.

3. Standard thread pitch lookup table

4. Standard thread types

In engineering, people don’t just use a certain type of lace. Some types of thread can be mentioned as metric thread, British thread, pipe thread… Here are some commonly used standard thread types:

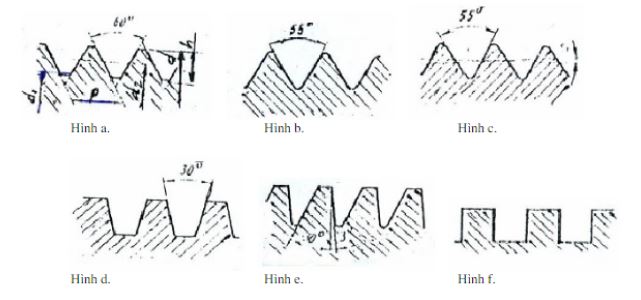

– Metric thread: Metric thread profile is an equilateral triangle whose unit of measurement is mm, symbol M. Metric thread includes 2 types: Large step metric thread and Small step metric thread. These two types of threads have the same fkihs but different pitches. (Picture A)

– Metric taper thread: The profile of a metric taper thread is a triangle with a vertex of 60 degrees, the unit of measure is mm and the symbol is MK (Figure a).

– Pipe thread: A thread used in pipe joints, whose profile is an isosceles triangle, the apex is an angle of 55 degrees, measured in inches (Figure b, c). Pipe thread includes 2 types:

- Cylindrical pipe thread: The symbol is G with the dimensions specified in TCVN 4681 – 89.

- Conical pipe thread: The symbol is R with the dimensions specified in TCVN 4681 – 88.

– Round thread: With the profile as circular arc, unit mm and symbol Rd. Used with shelled parts. The dimensions of round threads are specified in TCVN 2256 – 77.

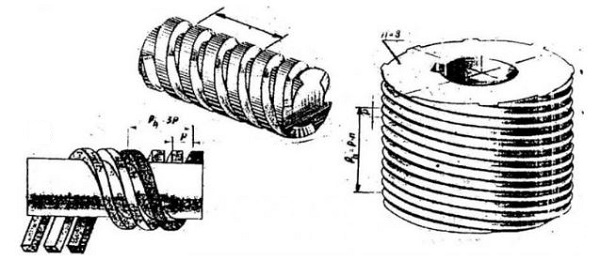

– Trapezoidal thread: The type of thread with the profile is isosceles trapezoid, apex angle of 30 degrees, unit of measurement mm, symbol Tr. Includes single-point trapezoidal lace and multi-point trapezoidal lace. The size of trapezoidal thread is specified in TCVN 2254 – 77 and TCVN 2255 – 77 (Figure d).

– Square lace: It is a type of thread that is created according to the requirements of use according to the figure f.

– Serrated thread: The profile is a regular trapezoid with a top angle of 30 degrees, the unit of measurement is mm and the symbol is S (Figure e).

4. Standard thread designation

In addition to the representation of the thread according to the figure, the thread symbols specified in TCVN 204-66 must be used.

Thread symbols must clearly state the thread profile (including outside diameter and pitch), twist direction and number of connections. Inside:

- Threaded profiles are denoted by an abbreviation specific to the thread name profile. (M for metric thread, Um for pipe thread and T for ladder thread).

- If the thread normally has a right helix direction and a single point, the standard permits this symbol to be omitted.

- The thread designation is written according to the dimensions and on the dimension line of the thread outside diameter and pitch, the two numbers are separated by an x. Example: M20 x 1: Is a metric thread with an outside diameter d = 20mm and a pitch p = 1mm.

Other example: M 12. Right means metric thread with outside diameter d = 16mm, standard pitch 1.75mm for unmarked joint, thread with right helix direction.

Box 2″ means pipe type thread with outside diameter d = 2″, with standard pitch (large pitch – see table). Right twist direction (no recording allowed).

For threads with many clues, the symbol can be as follows:

- 3 joints M 40 x 1 left.

- 4 T-joints 30 x 3.

Note: For threads with multiple joints, the size of the thread indicated on the symbol will be the size of the pitch.

- Closed threaded hole (shallow threaded hole, not through): It is allowed to write the word closed at the end of the thread symbol.

- Important threaded joints (must be tight without axial loose, self-braking, axial load, dynamic load…), threaded joints need to have their own tolerance regime and are marked with the number of steps exact, where necessary is indicated at the end of the thread designation.

Example: M 16 x 1 level 3

T 36 x 6 level 3

Above we have clarified what is lace? as well as what thread is used for in mechanical processing, standard thread steps. If you have any further questions, please leave a comment to be answered.