The rapid evolution of digital technologies is reshaping how factories operate, and by 2025, industry 4.0 and advanced automation trends are set to push the manufacturing sector into an unprecedented phase of intelligent innovation. As manufacturers continue to prioritize efficiency, customization, and data-driven operations, embracing these smart technologies becomes essential to remain competitive. This article explores the most transformative industry 4.0 automation trends that will impact manufacturing in 2025 and beyond.

Top Industry 4.0 Automation Trends to Watch in 2025

1. AI-Powered Predictive Maintenance

Artificial intelligence continues to play a pivotal role in industrial environments. In 2025, predictive maintenance—powered by AI and machine learning—will help companies minimize downtime and reduce repair costs. By analyzing historical and real-time data, systems can anticipate equipment failures before they happen, allowing for timely intervention.

2. Digital Twins Revolutionizing Manufacturing

Digital twin technology, a core aspect of industry 4.0, enables the creation of real-time virtual models of machinery, production lines, and even entire facilities. This allows manufacturers to simulate, predict, and optimize processes in a risk-free environment, leading to improved quality and reduced costs.

3. Industrial IoT (IIoT) and Smart Connectivity

The Industrial Internet of Things (IIoT) is becoming the backbone of smart factories, connecting machines, sensors, and control systems. In 2025, expect to see more widespread adoption of IIoT solutions that offer real-time insights, enhance productivity, and empower data-driven decision-making across the supply chain.

4. Human-Robot Collaboration (Cobots)

Collaborative robots—or cobots—are transforming shop floor dynamics. Unlike traditional robots that operate in isolation, cobots work safely alongside human workers, enhancing flexibility and scalability. Smaller manufacturers, in particular, will benefit from cobots as an accessible automation solution.

5. Edge Computing Brings Data Closer

As data generation increases on the factory floor, edge computing offers a practical solution by processing data closer to its source. This minimizes latency, increases responsiveness, and supports real-time decision-making—important attributes for any high-performance manufacturing environment in 2025.

Benefits of Embracing Industry 4.0 in Manufacturing

Leveraging industry 4.0 and automation trends drives key operational benefits that position manufacturers for long-term growth:

- Enhanced productivity through automated workflows

- Improved quality control with real-time monitoring

- Faster time-to-market via agile and smart production lines

- Reduced operational costs through predictive analytics

- Greater sustainability with optimized resource usage

Future Outlook: Industry 4.0 Beyond 2025

The future of manufacturing lies in continuous innovation, fueled by industry 4.0 advancements. Beyond 2025, expect greater integration of blockchain for supply chain transparency, quantum computing for rapid data analysis, and enhanced cybersecurity protocols to safeguard industrial networks. Businesses that adopt a digital-first mindset will be best positioned to thrive in this smart manufacturing era.

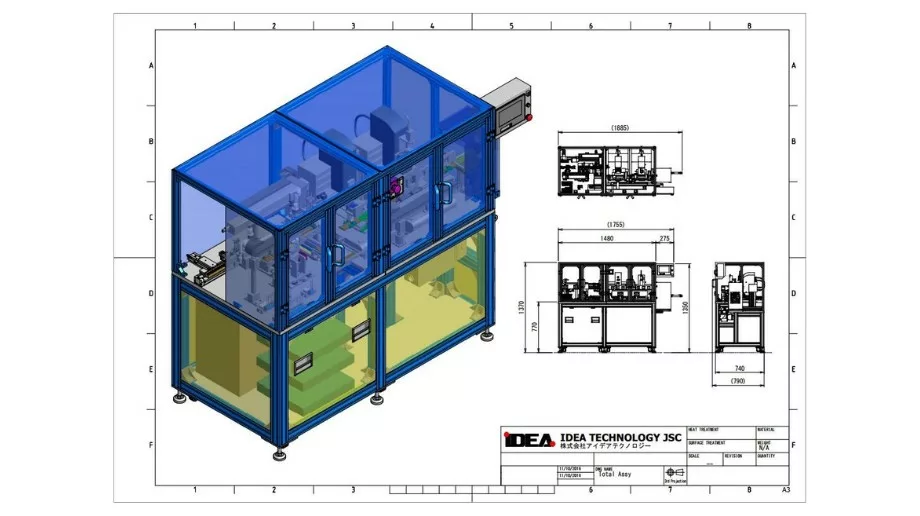

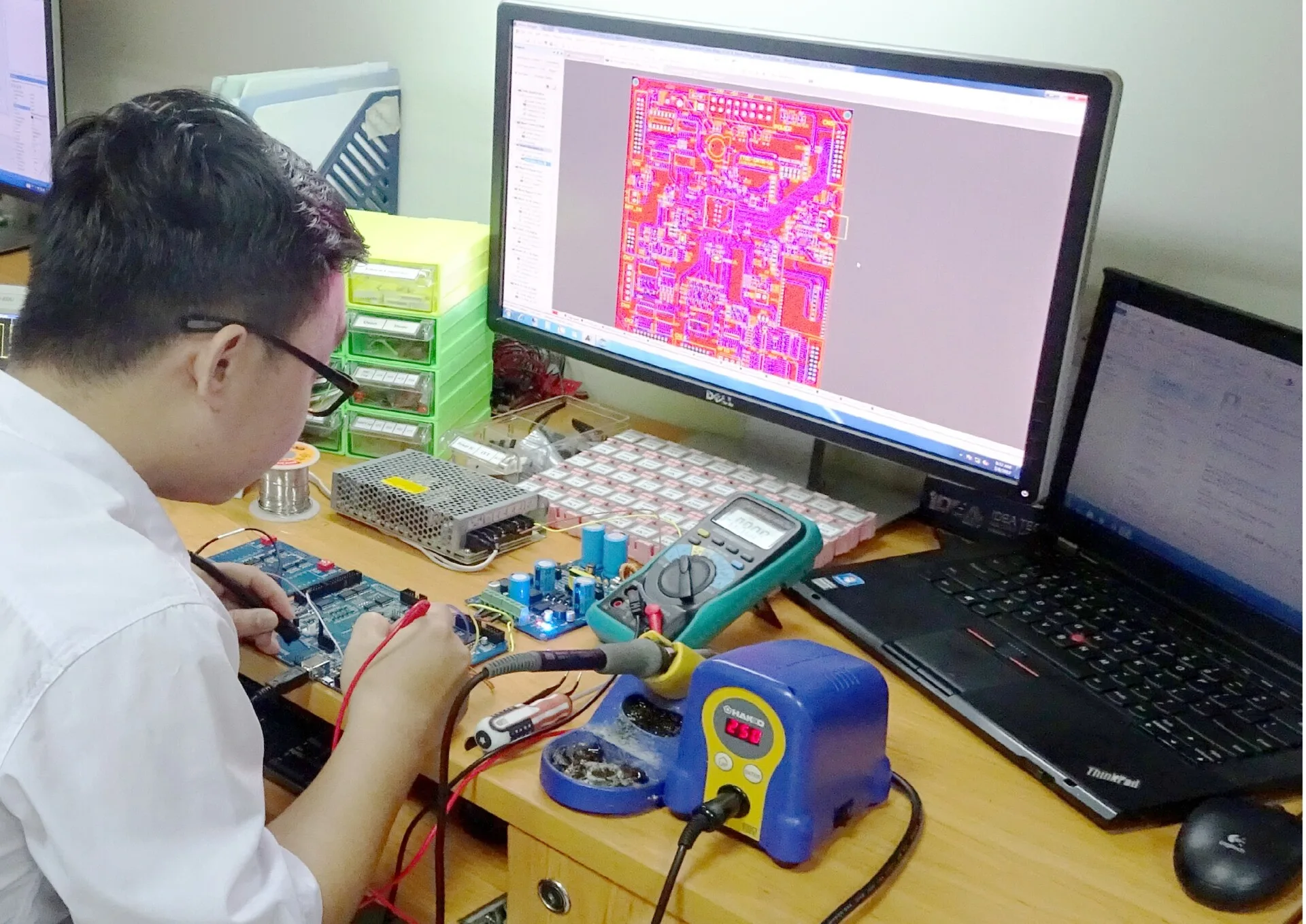

Partner with IDEA for Smart Manufacturing Excellence

Staying ahead of the curve requires strategic partnerships with experts who understand the intricacies of industrial innovation. IDEA is a trusted leader in Vietnam, delivering cutting-edge solutions in automated machine design and industrial process optimization. Whether you’re seeking improved efficiency or complete digital transformation, our team can help you unlock the full potential of industry 4.0.

Explore our end-to-end services at IDEA Techmart and learn how we can drive the future of your manufacturing operations.

Ready to elevate your automation journey? Connect with IDEA today to discover smart, scalable, and sustainable solutions that align with the automation trends defining the future.