lectronic component manufacturing

lectronic component manufacturing

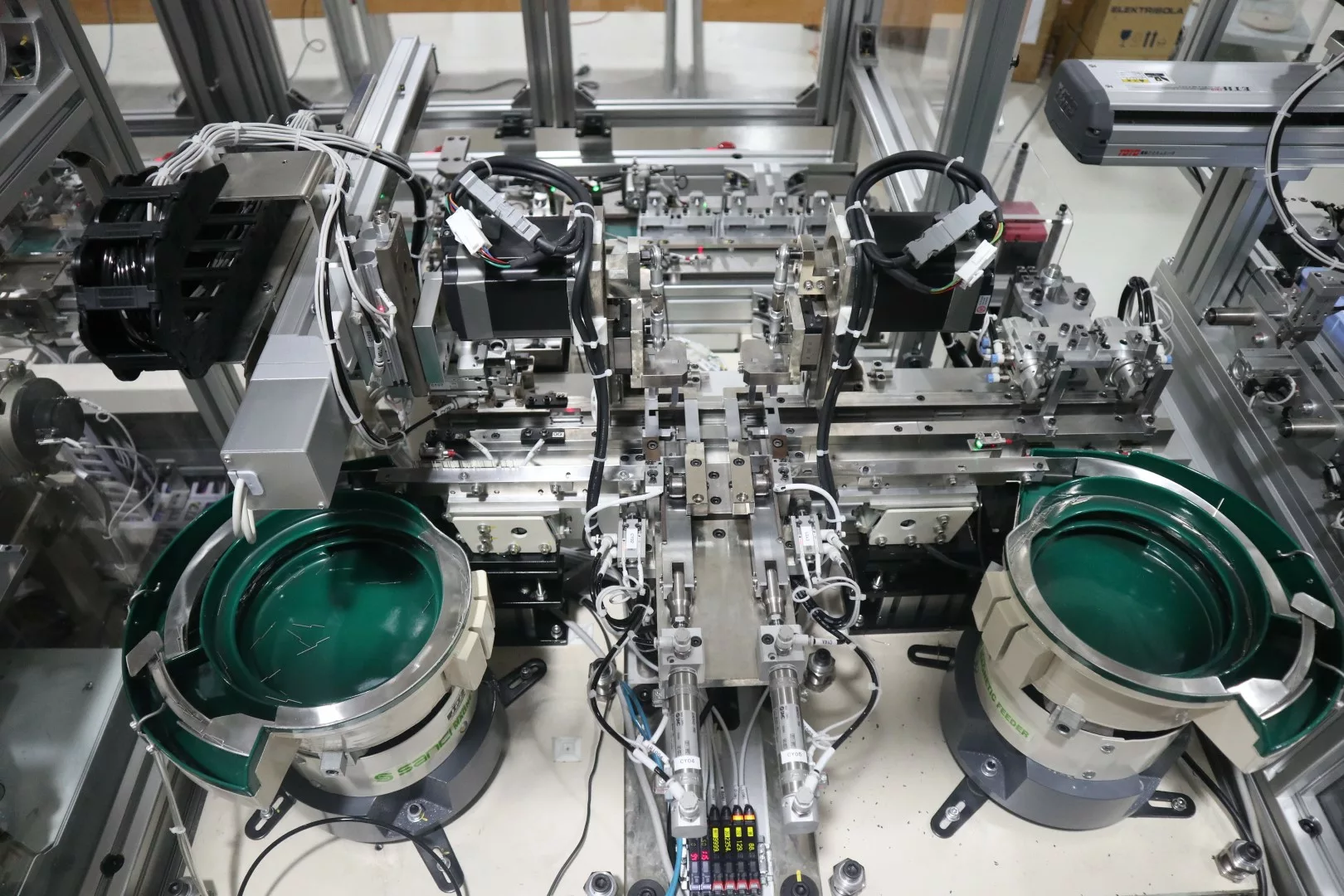

Design, manufacturing, and installation of an automated machine for feeding, assembling, and visual inspection of small electronic component modules such as connectors.

“IDEA Technology delivered a precise and stable system that helped us reduce labor needs while ensuring the highest product quality. The project was completed on schedule, and the team was highly professional.”

The client is FDI specializing in manufacturing electronic components for international brands. Previously, the processes of assembly and inspection were done manually, leading to time inefficiencies and a high error rate. The objective was to fully automate the processes of component feeding, assembly, and inspection in order to improve production speed and reduce dependence on manual labor.

Small components with varying geometries made manual feeding difficult and prone to misalignment.

Required high speed (≥ 25 products/min) and precision (±0.05 mm).

Needed integration of vision inspection to eliminate NG (non-conforming) products.

Limited factory floor space required a compact, layout-optimized design.

Deployed two vibrating bowl feeders to supply two types of components simultaneously, accurately oriented via mechanical guidance.

Designed an assembly mechanism using pneumatic cylinders combined with servo motors to perform inserting, pressing, and pushing operations.

Integrated an industrial camera system to inspect component shape, placement accuracy, and detect cosmetic defects.

HMI interface allowed operators to monitor system status and save inspection results by product code (with optional QR traceability).

Automatically sorted OK/NG products into separate trays.

Tripled productivity compared to the previous manual process (up to 30 products/min).

Reduced assembly errors by over 95%, significantly improving product reliability.

Saved 4 operator positions per machine, lowering long-term labor costs.

Inspection data is automatically stored, enabling traceability and enhanced quality control.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.