1. Rapidly scale engineering resources on demand

Easily add CAD engineers during peak workloads, short-term projects, or production expansions without the complexity of permanent hiring.

2. Cost- and time-efficient staffing solution

Contract-based engineering support helps optimize workforce budgets while reducing recruitment, training, and long-term employment costs.

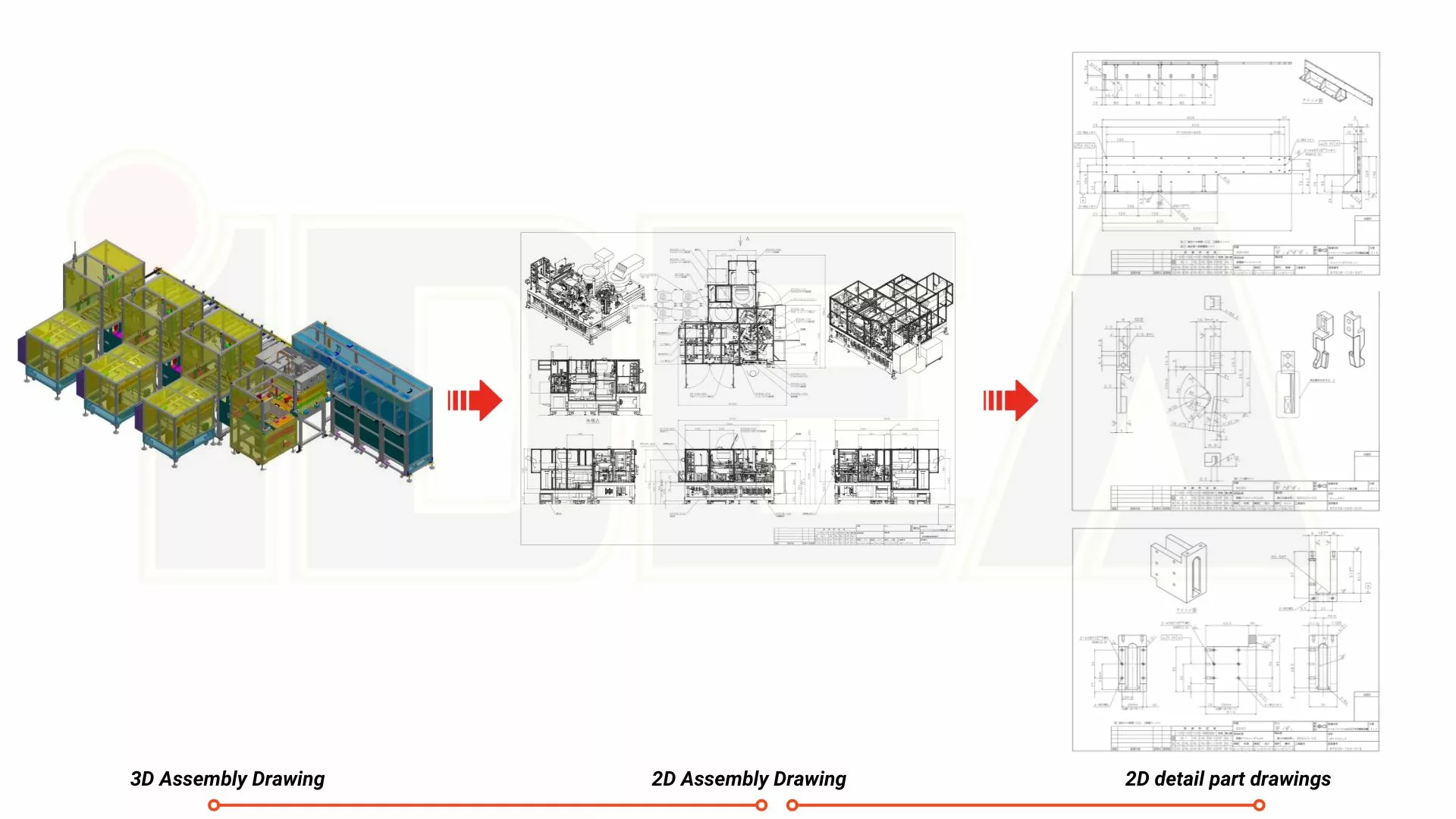

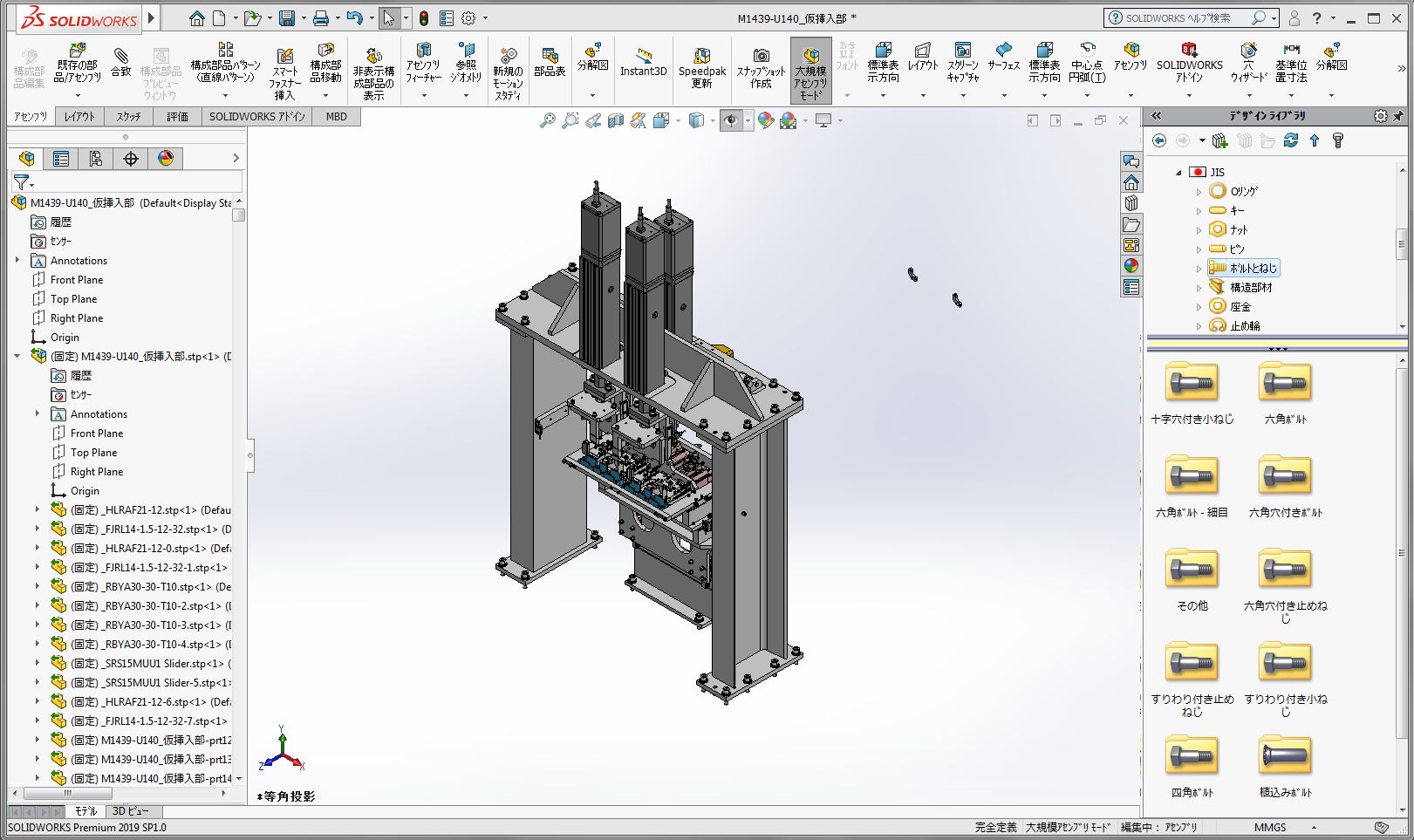

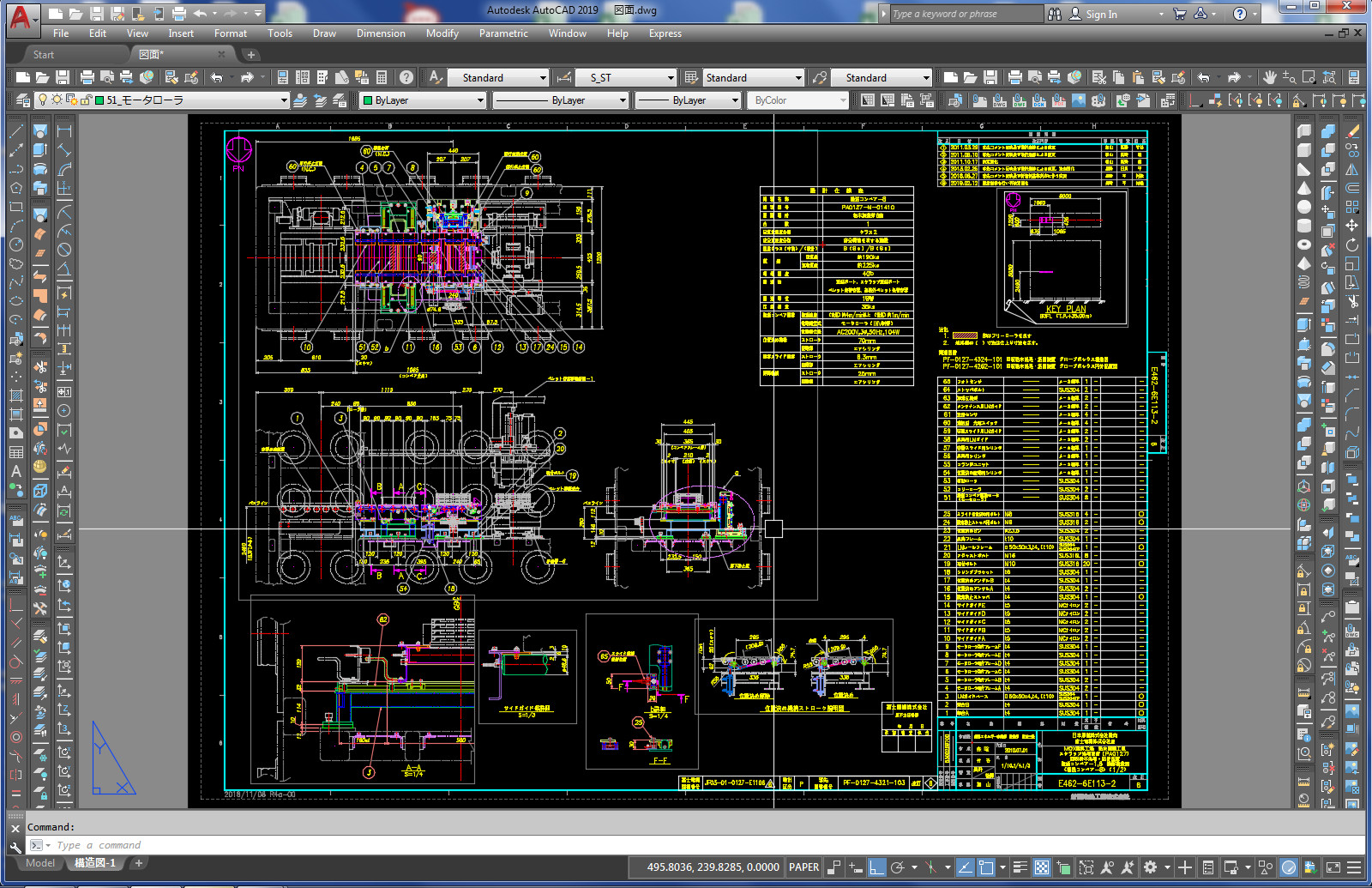

3. Professional CAD engineering services

IDEA Group delivers accurate, high-quality CAD design services that meet technical requirements, shorten product development cycles, and minimize errors.

4. Flexible mechanical design outsourcing

Our mechanical design outsourcing services adapt seamlessly to project scope, industry requirements, and different manufacturing models.

5. Engineers aligned with international standards

IDEA Group’s CAD engineers bring global project experience and strong knowledge of international engineering and manufacturing standards.

6. A reliable solution delivered by IDEA Group

We ensure quality, on-time delivery, and data security, partnering closely with clients throughout the entire engineering project lifecycle.

To meet diverse project requirements and operational structures, IDEA Group offers multiple design and drafting support service models. Each model is designed to provide the right balance of flexibility, cost efficiency, management control, and long-term scalability. This comparison outlines the key differences between Spot Contracts, Dedicated Contracts, and Offshore Models, helping clients select the most suitable engagement approach based on project scope, resource needs, and internal management capabilities.

| Item | Spot Contract

(Hourly-based pricing) |

Contract CAD Engineer

(Fixed team – No client management) |

Offshore Design

(Fixed team – Client-managed) |

|---|---|---|---|

| Description | Services are provided based on specific requirements for each project, with pricing defined per case. | A fixed team is provided on a long-term basis. The client does not directly manage the team; IDEA guarantees talent supply and quality. | A fixed team is provided, while the client directly manages daily tasks and project progress. |

| Management Scope | IDEA manages the project scope, resources, and execution, ensuring delivery. | IDEA manages personnel and ensures consistent quality. | The client directly manages personnel, work quality, and progress. |

| Flexibility | High flexibility, easily adjustable to specific project needs. | Adjustable to client requirements, but based on a fixed team structure. | High flexibility in team management, allowing the client to scale resources as needed. |

| Cost Structure | Quote-based pricing according to project requirements. | Primarily fixed costs, usually under a minimum one-year contract. Additional costs are quoted separately. | Pricing is tailored to client needs and includes recruitment, training, and system setup costs. |

| Commitment Level | Short-term commitment on a per-project basis. | Mid-term commitment (minimum one year). | Long-term commitment, with full responsibility for team and work management by the client. |

| Project Type | Short-term projects, specialized tasks, or one-off assignments. | Long-term projects requiring stable and continuous engineering resources. | Long-term projects requiring advanced security and strict management control. |

| Advantages | High flexibility and fast response to short-term needs. | Stable resource allocation and reduced training time. | Direct control over operations, recruitment, and training.High security and fully dedicated teams. |

| Disadvantages | May be costlier for long-term, high-volume projects compared to other models. Commitment to resource availability is not guaranteed. | Although staff are dedicated, the engagement is limited to talent provision. Clients are not deeply involved in hiring or people management and cannot communicate directly with engineers. | Requires strong people-management capabilities from the client and additional time investment for team management. |

IDEA Group offers high-precision machining services to turn detailed CAD designs into fully functional components and assemblies. Utilizing advanced CNC machines, milling, turning, and surface finishing technologies, we ensure tight tolerances, superior surface quality, and consistent reproducibility. Our precision machining capabilities support prototyping, small-batch production, and large-scale manufacturing, providing clients with reliable, ready-to-assemble parts that meet the highest industrial standards.