Case study | Building design teams and transitioning processes from China to Vietnam

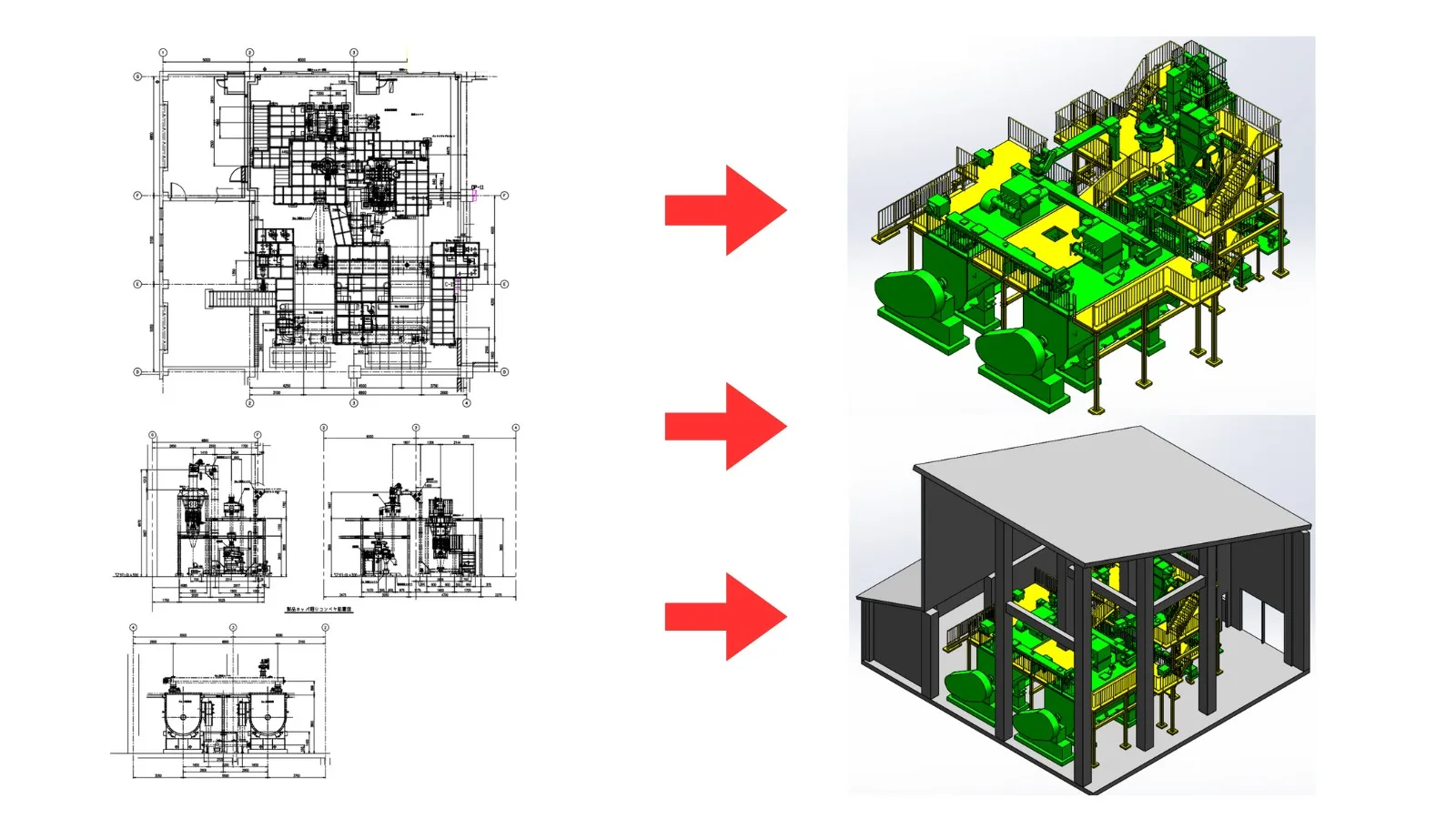

Challenge The client is a major Japanese contractor specializing in powder transport plant systems, with over 100 years of history. Most of their designers are elderly, with an average age of 70, and there is no successor to continue the work. To ensure sustainable development in the future, the client recognized the need to seek […]