Mastering Semiconductor Design Challenges: How a Japanese Startup Overcame Personnel Shortages with IDEA’s Support

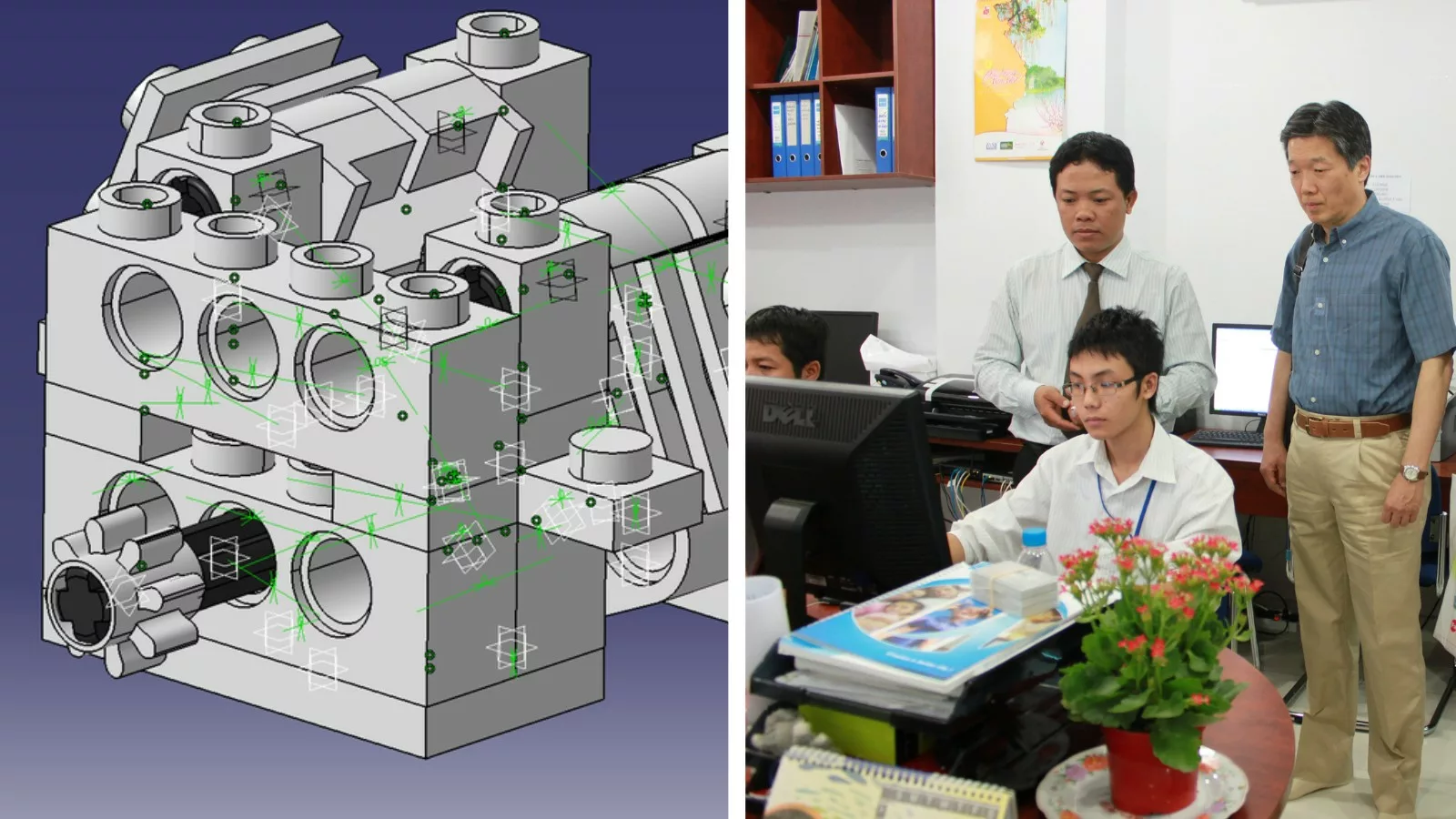

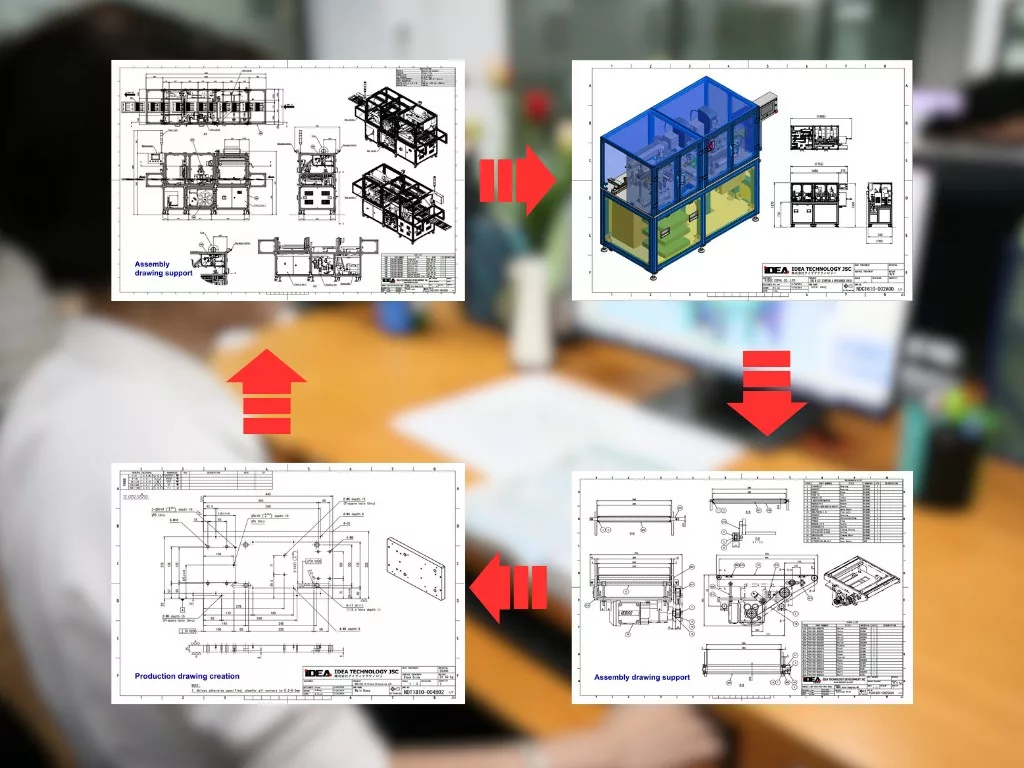

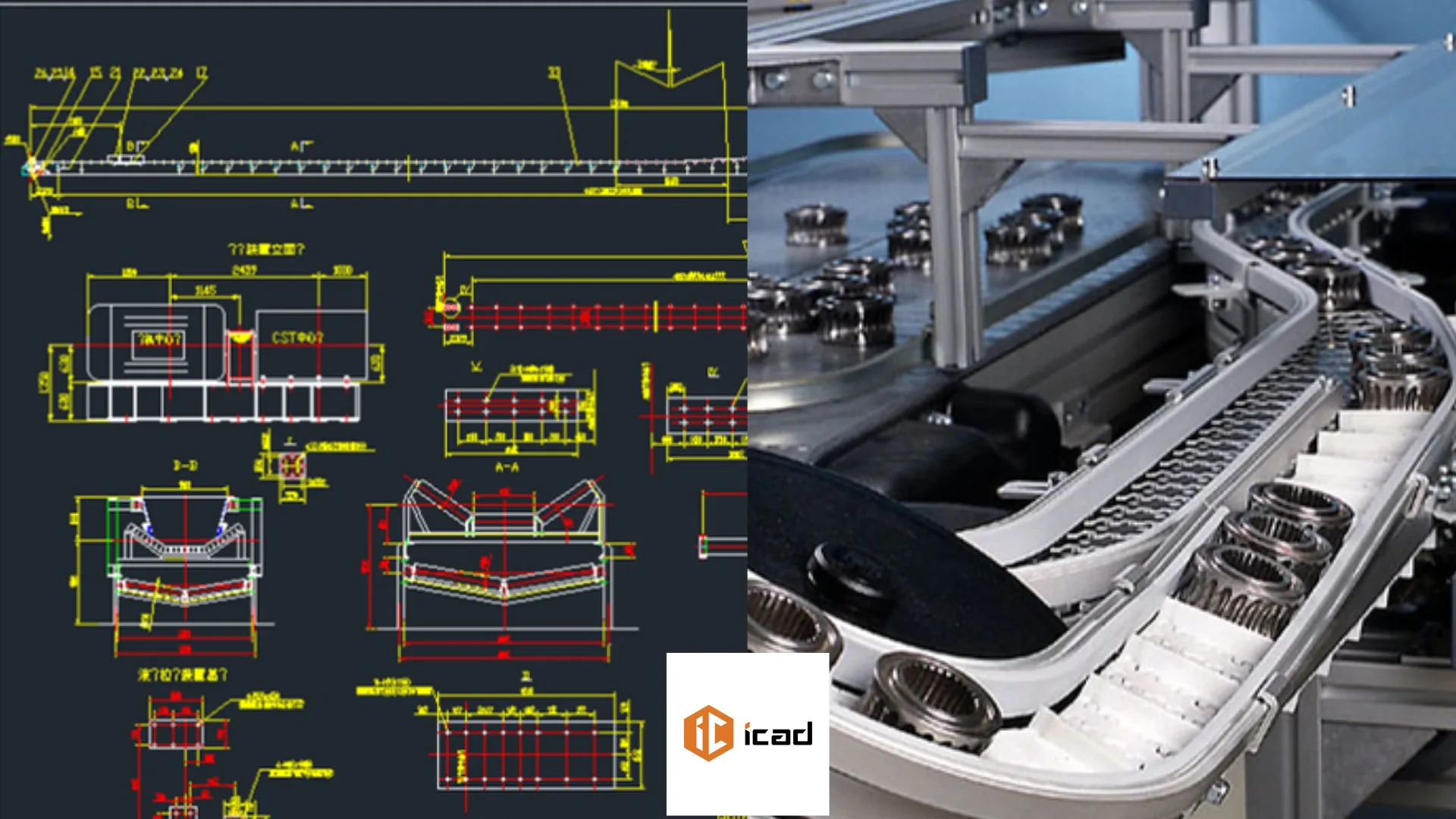

Challenges A startup in the semiconductor design and manufacturing sector in Japan, with only 3 years of experience, consists of a small group of engineers capable of designing from concept, programming, and assembly. However, this company faces difficulties due to a shortage of design personnel to carry out detailed designs and produce manufacturing drawings, which […]