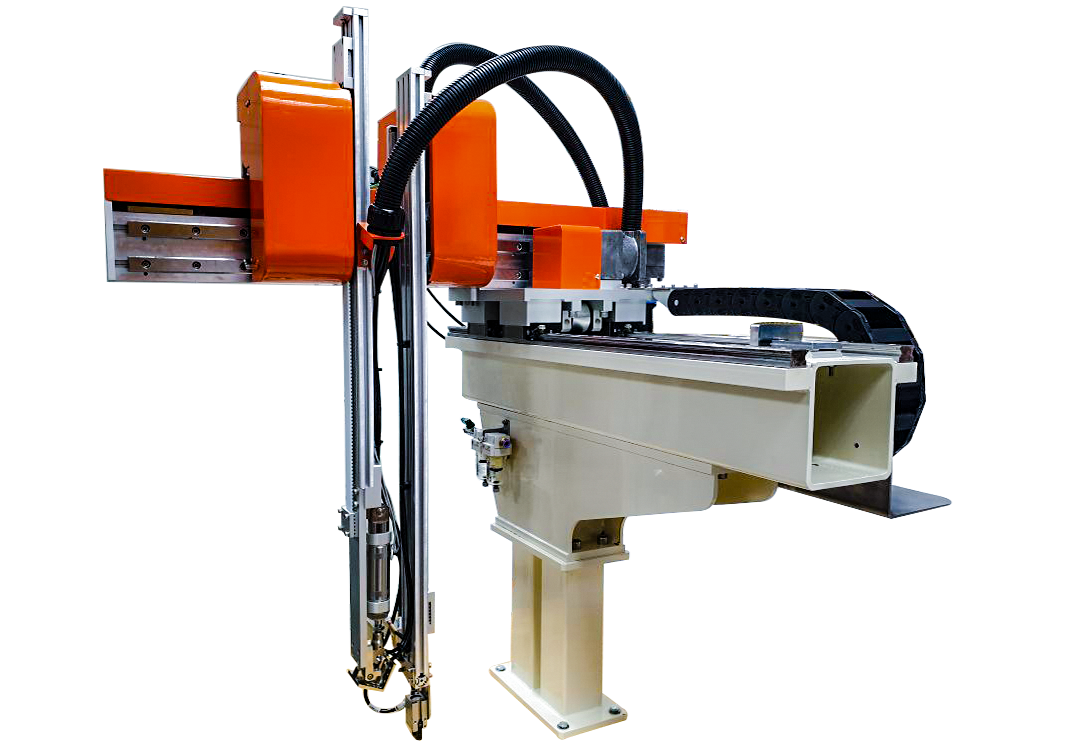

The IGR-GRM three-axis pick-and-place robot is a specialized automation solution for injection molding machines, designed to automatically remove products and runners from molds. With its lightweight structure, high precision of ±0.05 mm, and stable performance, this robot helps manufacturers increase productivity, reduce labor costs, and ensure consistent product quality. Equipped with a five-axis absolute servo control system and an intuitive touch-screen interface, it offers easy operation and seamless integration. Ideal for injection molding machines with a clamping force of 50 tons or less, IGR-GRM is the perfect choice for businesses seeking efficiency and reliability in automated production.

| Item | Details |

|---|---|

| Series | IGR-GRM |

| Order Code | IGR-GRM-X□□□-Y□□□ |

| Model | IGR-GRM-X090-Y023 IGR-GRM-X090-Y028 IGR-GRM-X120-Y023 IGR-GRM-X120-Y028 |

| Stroke | X Stroke: 900 mm or 1200 mm Y Stroke: 230 mm or 280 mm Z Stroke – Product: 350 mm Z Stroke – Runner: 450 mm |

| Robot Mass | 80 – 100 kg |

| Applicable Injection Molding Machine | 50 tons or less |

| Servo Axes | 5 Axes (Absolute) |

| Payload | 2 kg (Maximum) |

| Position Repeatability | ±0.05 mm |

| Voltage | 3P – 380V |

| Power Consumption | 2 kW (Maximum) |

| Control Interface | Touch Pendant |