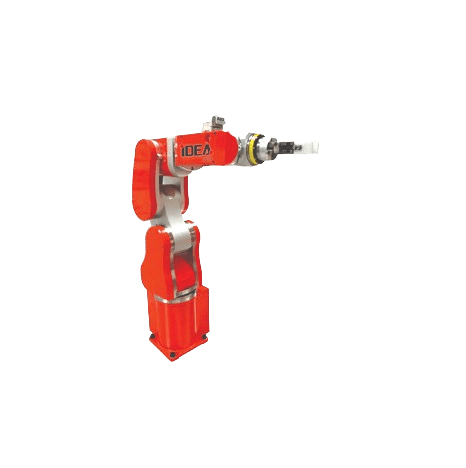

The IGR-SRR6-5 six-axis robot is a flexible automation solution designed for assembly, material handling, and precision operations in modern production lines. With a payload capacity of up to 4 kg, repeatability of ±0.03 mm, and high-speed performance across all axes, this robot delivers both productivity and accuracy for a wide range of industries. Its compact design with a 609 mm reach ensures easy integration into space-constrained environments, making it the ideal choice for manufacturers seeking efficiency and precision in automated processes.

| Item | Details |

|---|---|

| Series | IGR-SRR |

| Order Code | IGR-SRR□-□ |

| Model | IGR-SRR6-5 |

| Robot Type | Serial Robot |

| Number of Axes | 6 |

| Payload | 4 kg |

| Drive System | Servo motor |

| Max Working Envelope | Axis 1: ±135° Axis 2: -120° ~ 120° Axis 3: -110° ~ 145° Axis 4: ±190° Axis 5: ±120° Axis 6: ±360° |

| Max Speed | Axis 1: 250°/s Axis 2: 280°/s Axis 3: 280°/s Axis 4: 400°/s Axis 5: 450°/s Axis 6: 310°/s |

| Position Repeatability | ±0.03 mm |

| Max Reach | 609 mm |

| Air Tubes | φ4 × 2 |

| Robot Mass | 50 kg |

| Pendant Touch | Yes |

| Cabinet | Yes |

| Voltage | 1P-220VAC |

| Power Consumption | 2.2 kW |

| Acoustic Noise Level | 70 dB |

| Ambient Temperature | 20 – 45°C |