In today’s advanced manufacturing environments, PLC software plays a pivotal role in automation control and industrial efficiency. As machines become smarter and production lines more complex, the need for reliable, scalable, and easy-to-integrate control systems has never been higher. Programmable Logic Controllers (PLCs) provide a flexible solution for real-time decision-making, ensuring optimal operation across diverse industrial applications.

What is PLC Software and Why It’s Crucial for Automation Control

PLC software is used to program, monitor, and control hardware systems in industrial and manufacturing applications. It forms the backbone of automation control by interpreting signals from sensors and executing logical operations to drive actuators, motors, and machines. Designed for rugged environments, PLCs offer robust performance where traditional computer systems might fail.

The importance of PLC software lies in its ability to:

- Ensure precision and reliability in machine operations

- Enhance productivity through real-time monitoring and diagnostics

- Allow ease of reprogramming for flexible manufacturing setups

- Reduce human error and operational downtime

How PLC Software Powers Industrial Machines

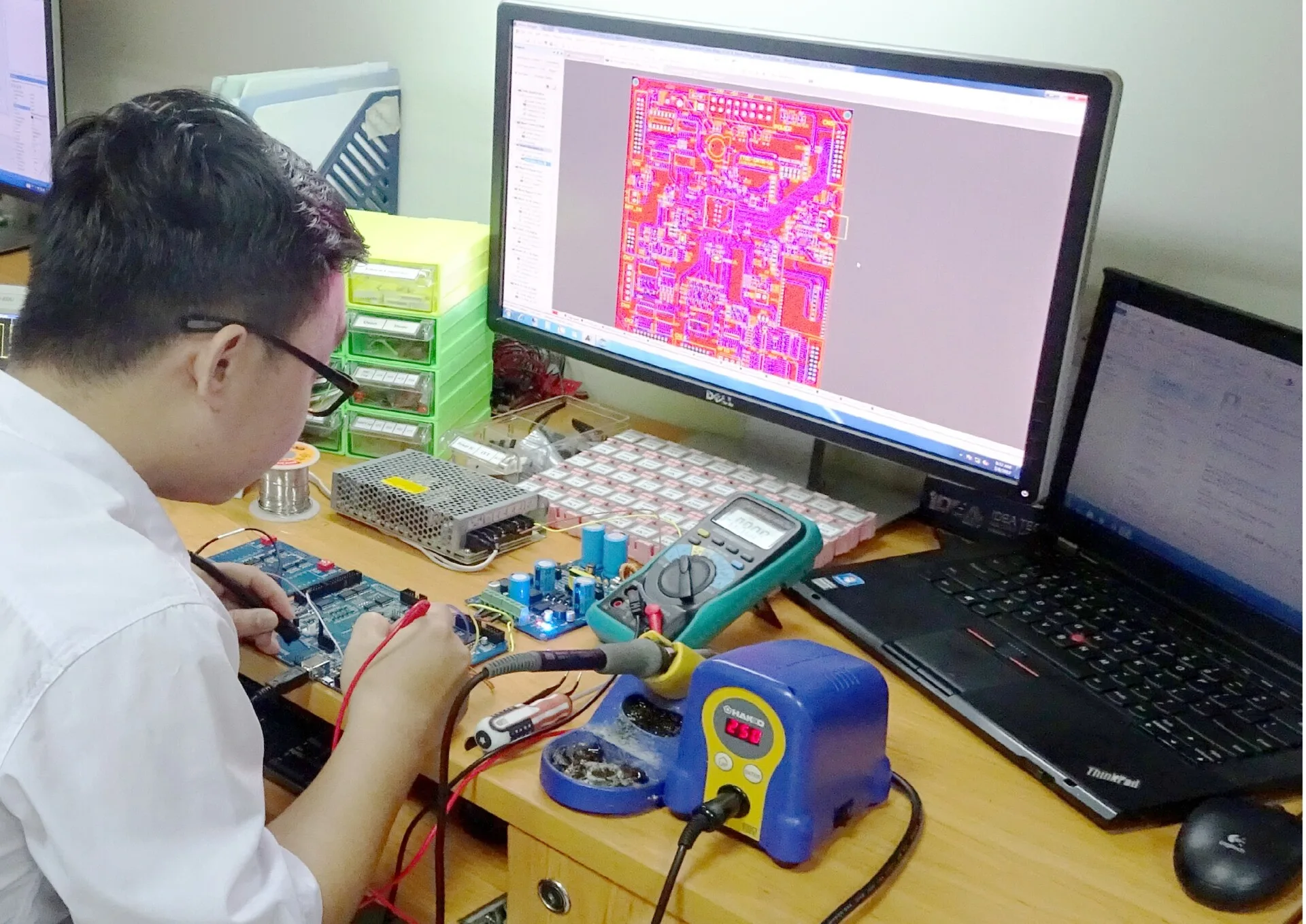

Modern industrial machines are equipped with sensors, motion controllers, and various I/O devices. PLC software integrates these components into a cohesive system, enabling seamless communication between the hardware and the control logic. The result is streamlined operation, consistent output, and predictive maintenance capabilities.

At IDEA Group, we specialize in machine design and automation, where implementing the right PLC system is crucial for enhancing operational efficiency across multiple industries such as automotive, electronics, and food processing.

Advantages of Using PLCs in Industrial Automation

Integrating PLC software into your production systems offers numerous advantages:

- Modularity: Easily scale or update control systems without overhauling infrastructure.

- Real-time control: Monitor processes instantly and apply changes to optimize performance.

- Error detection: Monitor equipment health and spot potential failures before they escalate.

- Customization: Tailor automation control to specific workflows or machinery setups.

Choosing the Right PLC Software for Your Industrial Needs

With various PLC platforms available in the market, selecting the optimal one depends on factors like system complexity, communication protocols, and desired outcomes. Well-known platforms include Siemens TIA Portal, Allen-Bradley RSLogix, and Mitsubishi GX Works. Each offers unique benefits in terms of user interface, integration, and scalability.

For businesses seeking to optimize their automation control, consulting with professionals ensures you receive tailored solutions aligned with your facility’s goals. At Che Tao May IDEA, you’ll find extensive experience in customizing PLC software for unique industrial challenges.

Trends in PLC-Based Automation Control

Industry 4.0 has significantly shaped the evolution of PLCs. Today, modern PLCs support advanced features such as:

- Cloud connectivity: Send and receive data to cloud-based dashboards for remote control.

- Integration with IoT: Communicate with a wide range of smart devices and sensors.

- Cybersecurity: Implement secure protocols to protect industrial software from threats.

- AI-powered analytics: Use machine learning to optimize machine operations based on data trends.

Platforms like IDEA Tech Mart offer insights and tools to stay ahead of these advancements, helping industries leverage the full power of industrial automation software.

Working with IDEA – Your Partner in Machine Automation

Whether you’re launching a new production line or upgrading legacy systems, partnerin

g with experts ensures smooth integration and future readiness. IDEA provides comprehensive solutions, from engineering design to PLC programming, aligning your machines with the latest automation standards.

Ready to transform your manufacturing processes with advanced PLCs, automation control, and industrial software? Connect with IDEA Group today and leverage our proven expertise in industrial machine automation design and deployment.