PLC programming and control software are at the heart of today’s smart machines, enabling unparalleled precision, automation, and efficiency in industrial operations. Whether in automotive, food processing, or electronics manufacturing, the integration of programmable logic controllers (PLCs) plays a critical role in streamlining workflows and enhancing overall machine performance. As Industry 4.0 advances, machine control systems continue to evolve—empowering businesses with intelligent automation solutions for competitive growth.

What is PLC Programming and Why It Matters

PLC programming involves creating logic-based programs for controlling industrial machines and processes. PLCs are ruggedized computers designed to operate in harsh factory environments and are essential for real-time automation tasks. These systems monitor inputs, make logical decisions, and control outputs based on predetermined logic sequences.

Here’s why PLC programming is critical for smart machines:

- Real-time Control: Ensures instant responsiveness in machine operations.

- Reliability: Proven resilience under extreme industrial conditions.

- Scalability: Easily adaptable for both simple machines and large-scale automated lines.

- Integration-ready: Seamlessly connects with HMIs, SCADA, sensors, and MES systems.

Role of Control Software in Smart Machines

Machine control goes beyond basic automation—it encompasses precision regulation, data analytics, and remote diagnostics. Control software interfaces with PLCs to program, simulate, and monitor machine performance, making smart machines more efficient and predictive in behavior.

Common control software functionalities include:

- Error detection and handling protocols

- Synchronized motion control for multi-axis machinery

- Process visualization via interactive HMIs

- Programmable alarms and system feedback loops

With advanced control software, operators can leverage dashboard visualizations and predictive maintenance alerts, drastically reducing unexpected downtime.

Smart Machines Powered by PLC Programming

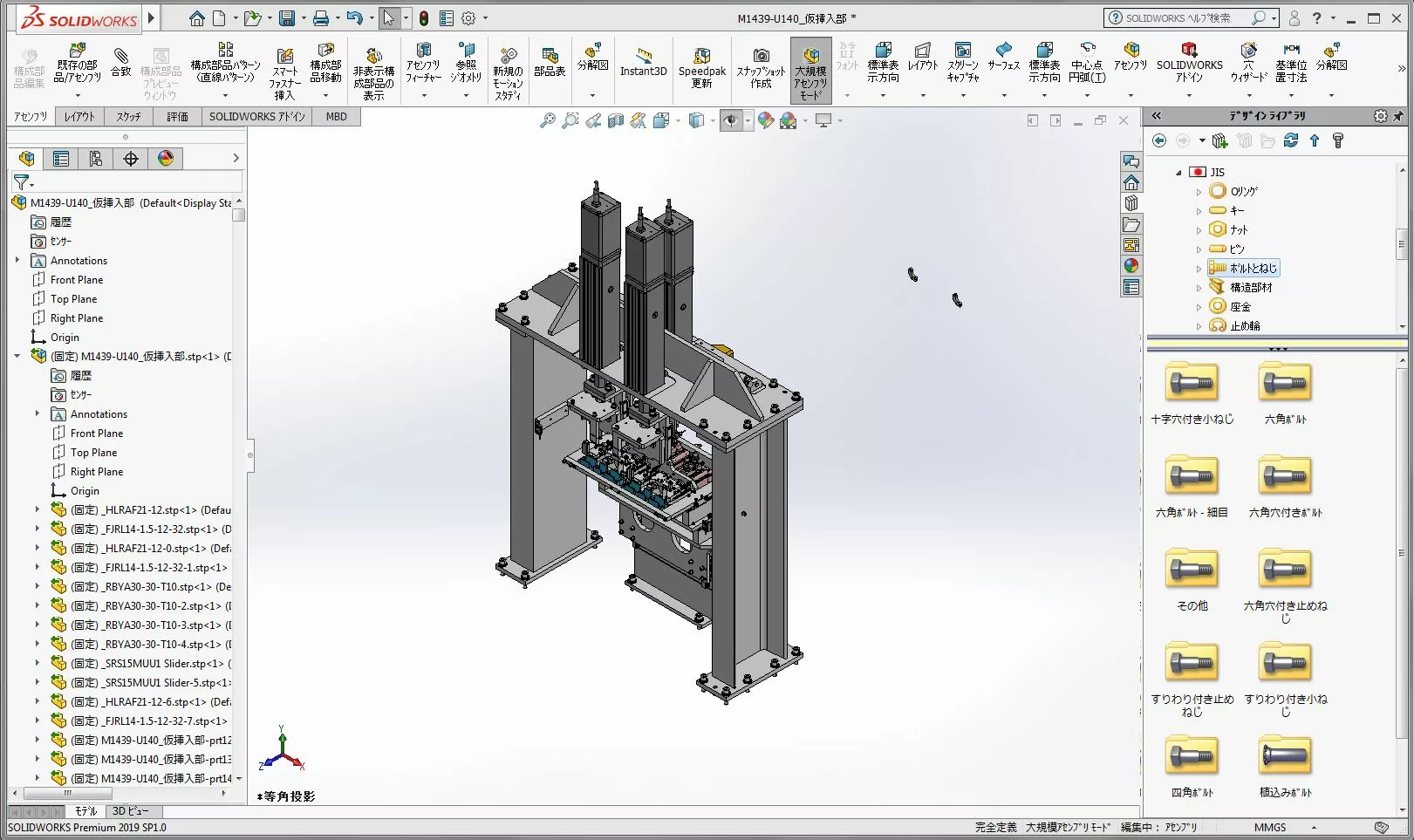

Smart machines equipped with PLC-driven control systems are transforming modern manufacturing. By integrating sensors, actuators, and real-time feedback mechanisms, these machines optimize every stage of production—from raw material handling to automated packaging.

Many smart automation solutions leverage technologies from specialists like IdeaTechMart, offering high-performance components and customizable automation tools. Additionally, companies like Cơ Khí IDEA specialize in mechanical manufacturing and control systems for specific industry needs.

Benefits of PLC Programming in Industrial Automation

Companies adopting PLC-based machine control systems gain measurable advantages in terms of productivity and cost-efficiency. Some of the top benefits include:

- Increased Machine Uptime: Quick fault diagnosis reduces lengthy downtime.

- Enhanced Flexibility: Fast reprogramming of machines supports different production batches.

- Energy Efficiency: Automated processes reduce waste and energy use.

- Data-Driven Decisions: Real-time data collection enables informed optimization strategies.

PLC Programming Expertise with IDEA

At IDEA Group Vietnam, our team of automation engineers combines deep domain knowledge with hands-on expertise in PLC programming and machine control systems. From conceptual design to deployment, we develop tailor-made solutions aligning with production demands of smart factories.

Explore our broad range of machine design and drafting services designed to enhance both new and existing production infrastructure. Whether it’s upgrading legacy control systems or implementing full-scale automation, we provide end-to-end engineering support with full transparency and commitment.

As industries continue to transform under digitalization and smart manufacturing trends, integrating precise PLC programming and intelligent machine control is no longer optional. These technologies form the foundation of future-ready industrial systems, driving innovation and operational excellence.

Ready to take your automation to the next level with reliable and efficient PLC programming and control solutions for smart machines? Partner with IDEA—your strategic ally in industrial machine design and intelligent manufacturing in Vietnam.