In today’s fast-evolving manufacturing landscape, PLC programming and advanced machine control software are at the heart of building smart machines that deliver precision, efficiency, and adaptability. These technologies not only enhance automation but also enable predictive maintenance, real-time diagnostics, and seamless data integration for industrial operations. As factories race toward Industry 4.0, integrating intelligent PLC-based control systems becomes a critical step for staying competitive.

Understanding PLC Programming in Modern Manufacturing

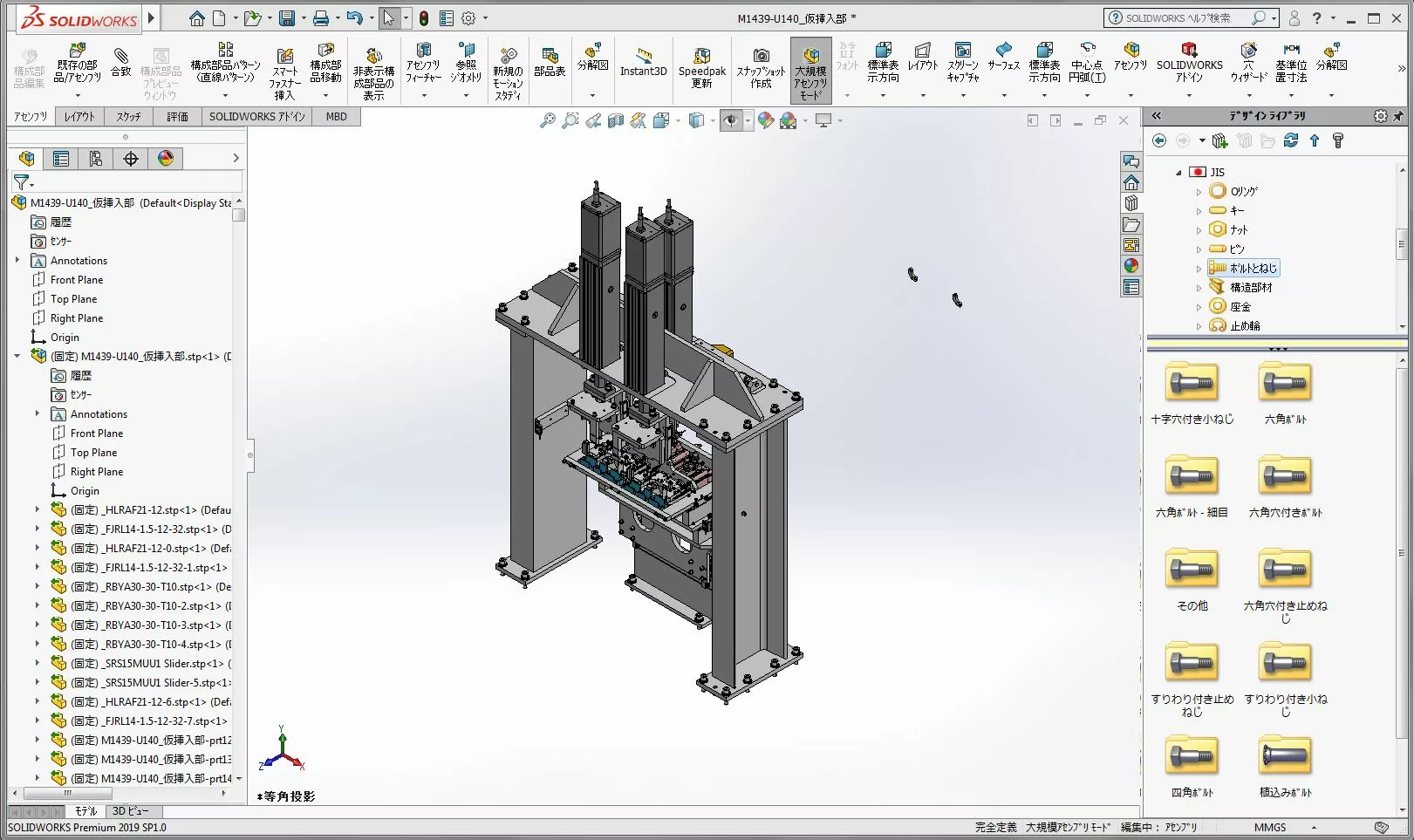

Programmable Logic Controllers (PLCs) are the brains behind most automated systems in industrial settings. They execute logic-based operations to control machinery and processes based on input/output (I/O) configurations. What sets PLC programming apart is its high reliability, real-time response, and ability to withstand harsh industrial environments.

From conveyor systems and robotics to packaging and CNC machines, PLCs automate complex sequences that drive productivity. Using ladder logic, structured text, or function block diagrams, engineers develop programs to meet the specific control needs of each operation.

Why Machine Control Systems are Essential for Smart Machines

Advanced machine control systems ensure that smart machines perform tasks with accuracy, repeatability, and minimal human intervention. These systems merge hardware like sensors, actuators, and drives with software that enables automation and communication within a connected ecosystem.

Benefits of integrating cutting-edge control systems into manufacturing include:

- Greater process transparency through real-time monitoring

- Improved production consistency and reduced cycle times

- Predictive analytics to minimize downtime

- Automated feedback and self-correction capabilities

How PLC Programming Drives Smart Machine Innovation

Smart machines leverage PLC programming to become autonomous, responsive, and integrated within broader industrial systems. With the help of IoT and cloud platforms, PLCs can now communicate with SCADA, MES, and ERP systems—transforming basic machines into intelligent assets.

Key advancements in PLC-based smart machinery include:

- Remote diagnostics and software updates

- Adaptive control based on sensor data and AI algorithms

- Modular programming for scalable applications

- Enhanced safety compliance via real-time feedback

To see emerging machine control solutions in action, visit Che Tao May IDEA, a specialized hub for mechanical design and innovation.

Choosing the Right Partner for PLC Programming and Machine Control

Implementing PLC programming and sophisticated machine control systems requires deep engineering expertise and domain knowledge. From initial design through to coding, testing, and commissioning, working with a qualified partner ensures optimal performance and seamless integration of your smart machines.

IDEA Group’s machine design and drafting services align mechanical systems with efficient control programming for complete industrial automation solutions. By combining PLC logic with customized HMI and SCADA integrations, IDEA helps manufacturers streamline production and improve flexibility.

Industries Benefiting from Smart Machine Automation

PLC-driven smart technologies are revolutionizing a wide range of sectors. Industries that gain the most from machine automation include:

- Automotive and electric vehicle production

- Food and beverage processing

- Electronics and semiconductor manufacturing

- Packaging and logistics systems

Companies sourcing smart machine components or industrial electronics can explore specialized technology solutions at IDEA Tech Mart.

Unlock the Power of Smart Machines with IDEA

The future of manufacturing lies in intelligent automation. By investing in expert PLC programming and integrated machine control systems, businesses can transform equipment into connected, efficient, and agile smart machines.

Whether you’re upgrading legacy systems or developing new machinery, IDEA Group Vietnam stands ready to help you navigate the path forward. Leverage our years of experience in making industrial machines work smarter and harder for your operations.

Start your automation journey today—contact IDEA to collaborate on your next smart machine project.