In today’s fast-paced manufacturing environment, integrating motion simulation into mechanical design has become essential for optimizing machine performance, reducing prototyping costs, and accelerating product development cycles. By simulating real-world movements early in the design stage, engineers can foresee operational behaviors, conduct thorough kinematic analysis, and make more informed decisions. This proactive approach not only minimizes errors but also enhances overall design accuracy and mechanical efficiency.

What is Motion Simulation in Mechanical Design?

Motion simulation refers to the virtual modeling of moving mechanical systems to predict how different parts will behave under specific conditions. When integrated into the mechanical design process, it allows engineers to:

- Visualize complex mechanical interactions

- Perform accurate kinematic and dynamic analysis

- Evaluate stress, strain, and motion paths prior to physical prototyping

- Optimize mechanisms to improve functionality and safety

Using reliable motion simulation tools enables design teams to foresee mechanical challenges and resolve them efficiently, enhancing design quality and reducing the need for costly revisions.

Benefits of Integrating Motion Simulation

Embedding motion simulation into mechanical design processes offers a wide range of advantages. Some of the most notable benefits include:

- Enhanced Accuracy: Kinematic analysis ensures each component moves as intended, reducing alignment errors and wasted manufacturing resources.

- Rapid Validation: Designers can validate motion paths and mechanical function without building physical prototypes.

- Improved Design Efficiency: Simulation tools allow for quicker iterations, leading to faster production readiness.

- Cost Savings: Early detection and correction of design flaws save time and reduce material waste.

Leading engineering firms like IDEA specialize in deploying simulation tools throughout their machine design and drafting services, ensuring higher reliability and performance in every project.

Motion Simulation and Kinematic Analysis: A Synergistic Approach

Kinematic analysis is a critical component of motion simulation, focusing on the geometry of motion without considering the forces that cause it. It plays a vital role in mechanical design by:

- Analyzing joint movements and trajectories

- Detecting potential collisions or interferences

- Ensuring proper synchronization between parts

Through advanced simulation, engineers can model and evaluate mechanisms such as cams, linkages, and gears more precisely, thereby optimizing the dynamics and motion planning of machines.

To see real-world applications of these technologies, industrial innovators frequently reference platforms like Chetaomay IDEA for inspiration, industry case studies, and best practices.

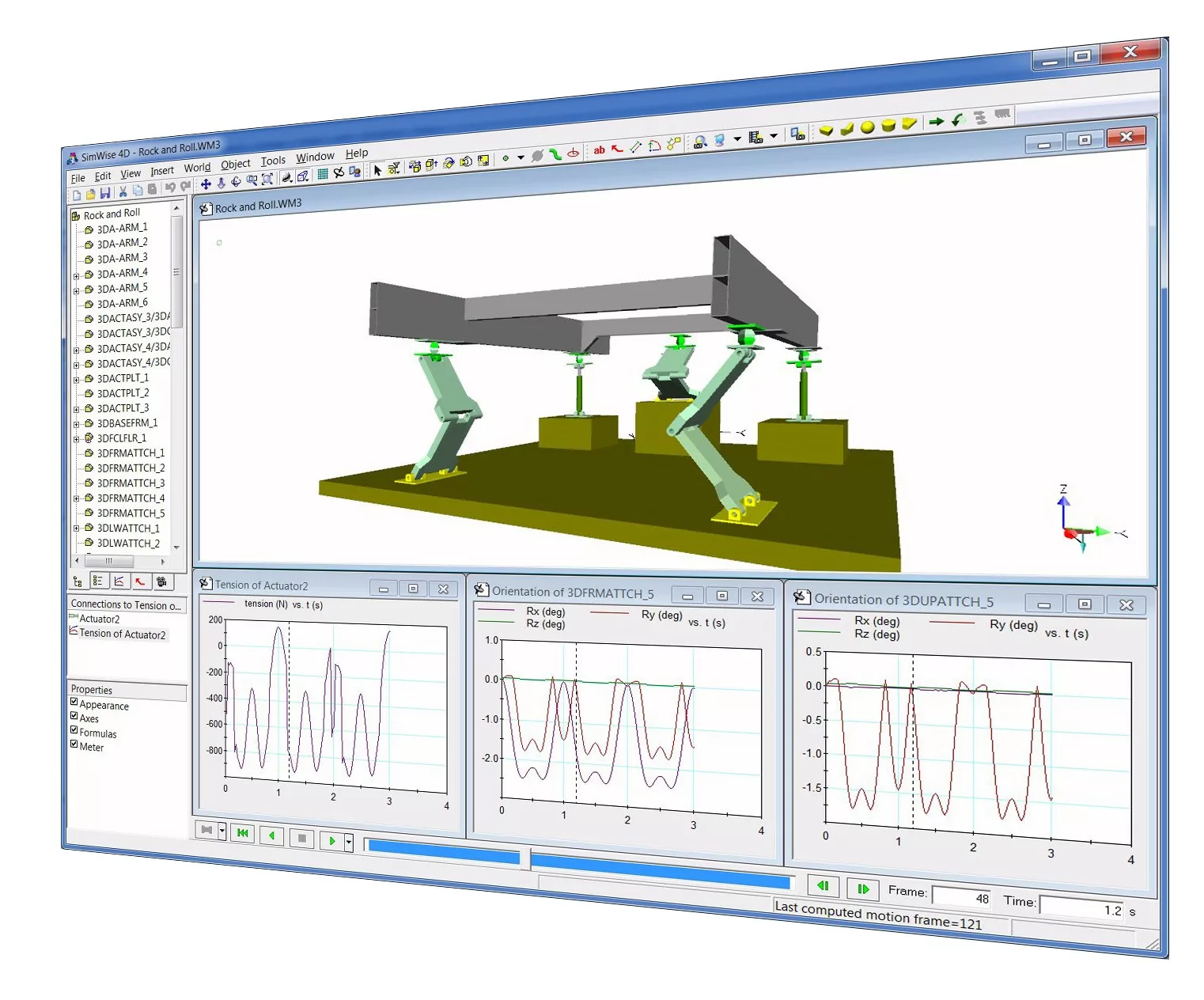

Tools and Technologies Enabling Better Motion Simulation

Modern CAD software comes integrated with powerful motion simulation modules that allow seamless transition from concept to analysis. Tools such as Autodesk Inventor, SOLIDWORKS Motion, and Siemens NX employ robust kinematic engines and intuitive interfaces to enable:

- 3D visualization of motion profiles

- Torque and force analysis

- Motion optimization under varying load conditions

These tools also support export-ready 3D models that can be used in downstream processes, including 3D printing, CNC machining, or automated assembly line planning.

For additional cutting-edge solutions in industrial design and equipment, visit IDEA Techmart – a trusted platform for automation and smart manufacturing systems.

Best Practices for Integrating Motion Simulation in Design Workflow

To maximize the return on motion simulation investments, engineering teams should adhere to the following best practices:

- Start simulation at the concept design phase to catch issues early

- Use real-world constraints and data for more accurate results

- Continuously update simulation parameters as new design details emerge

- Collaborate cross-functionally across design, simulation, and manufacturing teams

Leveraging a structured methodology ensures that motion simulation remains a proactive tool throughout the design lifecycle, driving innovation and efficiency.

Partner with IDEA for Advanced Mechanical Design Solutions

As motion simulation continues to evolve as a cornerstone of mechanical design, it becomes an indispensable part of delivering reliable, functional, and cost-effective mechanical systems. Integrating simulation and kinematic analysis not only elevates design integrity but also accelerates time-to-market in competitive industries.

Collaborate with IDEA — a trusted leader in industrial machine design and manufacturing in Vietnam — to harness the power of motion simulation for your next project. Visit our machine design and drafting services page to connect with our experts today.