Mechanical design plays a pivotal role in the development and integration of automation systems, especially within industries embracing mechatronics to streamline operations. As complex machinery evolves, the demand for precision-engineered mechanical components is growing rapidly, enabling more reliable, adaptable, and scalable production lines. Combining mechanical principles with intelligent electronics and control systems, mechanical design in automation ensures functionality, cost-efficiency, and long-term performance.

What is Mechanical Design in Automation Systems?

Mechanical design in the context of automation refers to the process of conceptualizing, engineering, and producing parts or assemblies to be integrated into automated machinery. This discipline not only includes the structural layout but also the functional mechanics that interact with electronic and software systems, central to mechatronics-based solutions.

Professionals working in this field must account for numerous operating variables such as motion control, load requirements, durability, and environmental conditions. All these details contribute to forming a system capable of operating with minimal human intervention while maximizing output quality.

Key Components of a Successful Mechanical Design Strategy

To develop efficient machinery in modern industry, engineers must follow a structured mechanical design methodology. This process typically includes:

- Needs assessment: Understanding client requirements, performance expectations, and automation goals.

- Conceptual sketches: Initial drawings that explore ideas and validate feasibility.

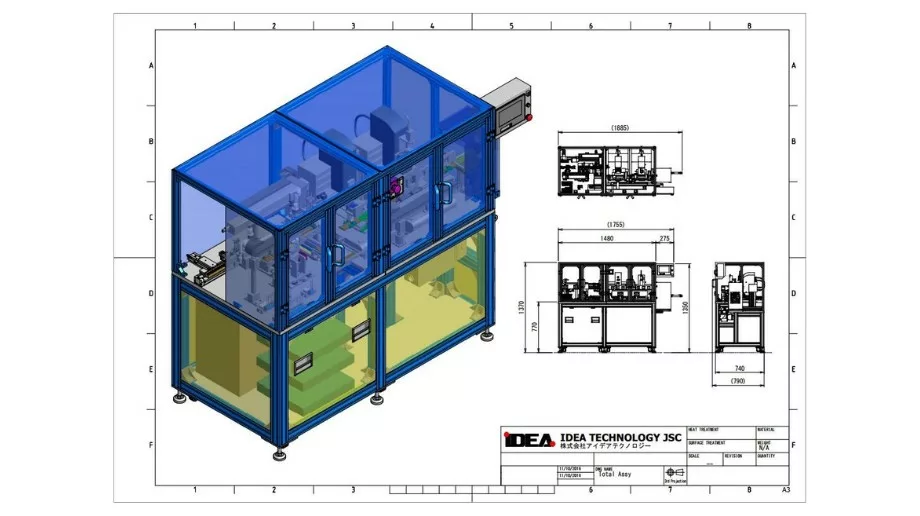

- CAD modeling: Precise 2D and 3D modeling to visualize designs and run simulations.

- Material selection: Choosing metals, plastics, or composites suited for stress, heat, and wear conditions.

- Prototyping and testing: Creating physical or virtual prototypes to identify flaws and optimize performance.

Mechatronics: Fusion of Mechanics, Electronics & Control

The role of mechanical design becomes even more crucial when integrated into mechatronics. This interdisciplinary approach blends mechanical systems with electronics, sensor technology, and software engineering. It ensures the intelligent function of machines, such as robotic arms, CNC machines, and automated packaging lines.

As industries adopt Industry 4.0 solutions, the synergy between mechanical and electronic systems becomes non-negotiable. Mechatronics enhances flexibility, real-time diagnostics, and responsiveness, placing greater demands on engineers to deliver optimized mechanical designs from the outset.

Benefits of High-Quality Mechanical Design for Automation

Incorporating refined mechanical design into automation provides companies with several tangible advantages, including:

- Increased productivity: Machines operate faster and with greater precision.

- Reduced maintenance: Thoughtfully engineered parts last longer, cutting operational downtime.

- Energy efficiency: Optimized mechanics result in lower energy consumption per cycle.

- Scalability: Modular mechanical designs simplify system upgrades or expansions.

Partnering with the Right Mechanical Design Experts

Designing automation systems is more than assembling parts — it demands collaboration with experienced professionals who understand both mechanical intricacies and the dynamics of mechatronics. At IDEA, our engineering team specializes in customized machine design that aligns perfectly with your production objectives and environment.

From concept to completion, our machine design and drafting services prioritize precision, aesthetic form, and robust functionality. We leverage modern tools and simulation software to mitigate errors, reduce iterations, and shorten development time.

If you’re exploring advanced automation solutions or seeking intelligent machine components, explore our portfolio on Che Tao May IDEA or find engineering components at IDEA Techmart — a trusted marketplace for industrial parts.

Why Prioritize Mechanical Design in Automation Projects?

At the core of reliable automation systems is a well-executed mechanical architecture. It serves as the foundation upon which hardware, sensors, and software function cohesively to deliver consistent and flexible performance. Investing in quality mechanical design early in the development phase leads to reduced costs and superior automation longevity.

Whether you’re developing custom machinery, retrofitting existing systems, or integrating smart controls, mechanical design ensures seamless alignment between function and form — paving the way for safe, efficient, and intelligent automation.

For companies seeking technical excellence and innovation, IDEA stands as a premier partner in Vietnam’s mechanical and automation industry. Leverage our years of expertise to transform your production capabilities with world-class automation designs.

Contact us today to collaborate with IDEA — your trusted mechanical design and automation partner for smarter manufacturing solutions.