Industrial Manufacturing – Management and Optimization of Production Processes

Industrial Manufacturing – Management and Optimization of Production Processes

IDEA Group offers management optimization solutions for a global aluminum manufacturing company, including the integration of CAD and ERP systems, automation of data entry and progress reporting, as well as standardizing contract processes and inventory management.

Location: A global aluminum manufacturing company with more than 10,000 employees

Production management system (PMS): custom-developed, managing inventory, production, and molds.

Accounting system: handles documents and financial reports.

Sales system: customized upon request, managing contracts and receivables.

Human resources system: manages HR and administration.

The systems are not synchronized, resulting in fragmented data that is difficult to manage centrally.

Sales staff manually input data into Excel, which easily leads to errors and low efficiency.

Data is manually compiled and analyzed, which is time-consuming and inaccurate.

The system cannot meet demands after scaling up and is prone to interruptions when many users access it simultaneously.

Pain points: Manual input of drawing information, inability to track real-time progress, data is unsynchronized and inaccurate.

Solution: Convert CAD drawing data into ERP, integrate information, manage data, and mold production processes.

Tools: CAD and ERP system integration, report extraction, mold inventory management.

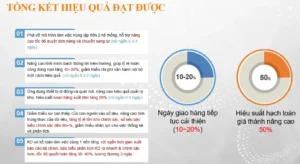

Results: Improved drawing editing efficiency and data management, enhanced production progress tracking and accuracy, increased efficiency by up to 80%.

Pain points: Manual processes, inaccurate order information, difficulty tracking production and delivery progress.

Solution: Automate data entry, standardize order data, and manage information directly on the system.

Tools: Automatic price updates, document management, progress reporting.

Results: Increased order processing efficiency, improved accuracy to 99%, optimized tracking and delivery processes.

Pain points: Complex management of contracts and orders, manual steps causing delays.

Solution: Standardize the contract process, and automate order conditions.

Tools: Automated contract settlement, and credit reporting.

Results: Increased contract settlement efficiency by 80%, and order approval efficiency increased by 60%.

Pain points: Difficulty in tracking real-time production progress, time-consuming planning.

Solution: Real-time production data tracking, and automated production planning.

Tools: Electronic progress tracking boards, and warning reports.

Results: 50% increase in work efficiency, faster completion of production planning.

Pain points: Inability to digitize production information.

Solution: Digitize the production system and information management.

Tools: Document functionality, tracking reports, standardized data.

Results: 100% digitization of the system, synchronized production and inventory data.

Pain points: Inability to provide instant reports, lack of timely QC data management.

Solution: Automate reporting processes, and manage quality and production stages.

Tools: PDA for data updates, electronic progress tracking boards.

Results: Increased QC report accuracy to 99%, and improved real-time production management.

Pain points: Inability to track and control purchasing, and manage delivery dates and product quality.

Solution: Use an electronic transaction platform and supplier evaluation system.

Tools: Electronic transaction system and supplier evaluation mechanism.

Results: Efficiency increased by 50-80%, accuracy reached 99%.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.