In the world of high-precision manufacturing, the importance of jigs and fixtures in ensuring product accuracy, repeatability, and efficiency cannot be overstated. These specialized workholding devices play a critical role in enhancing the precision machining process by stabilizing components and guiding tools with consistent accuracy. As demand for complex, high-tolerance parts continues to grow across industries like aerospace, automotive, and electronics, the strategic design of jigs and fixtures becomes a core competency in modern industrial environments.

Understanding Jigs and Fixtures in Precision Machining

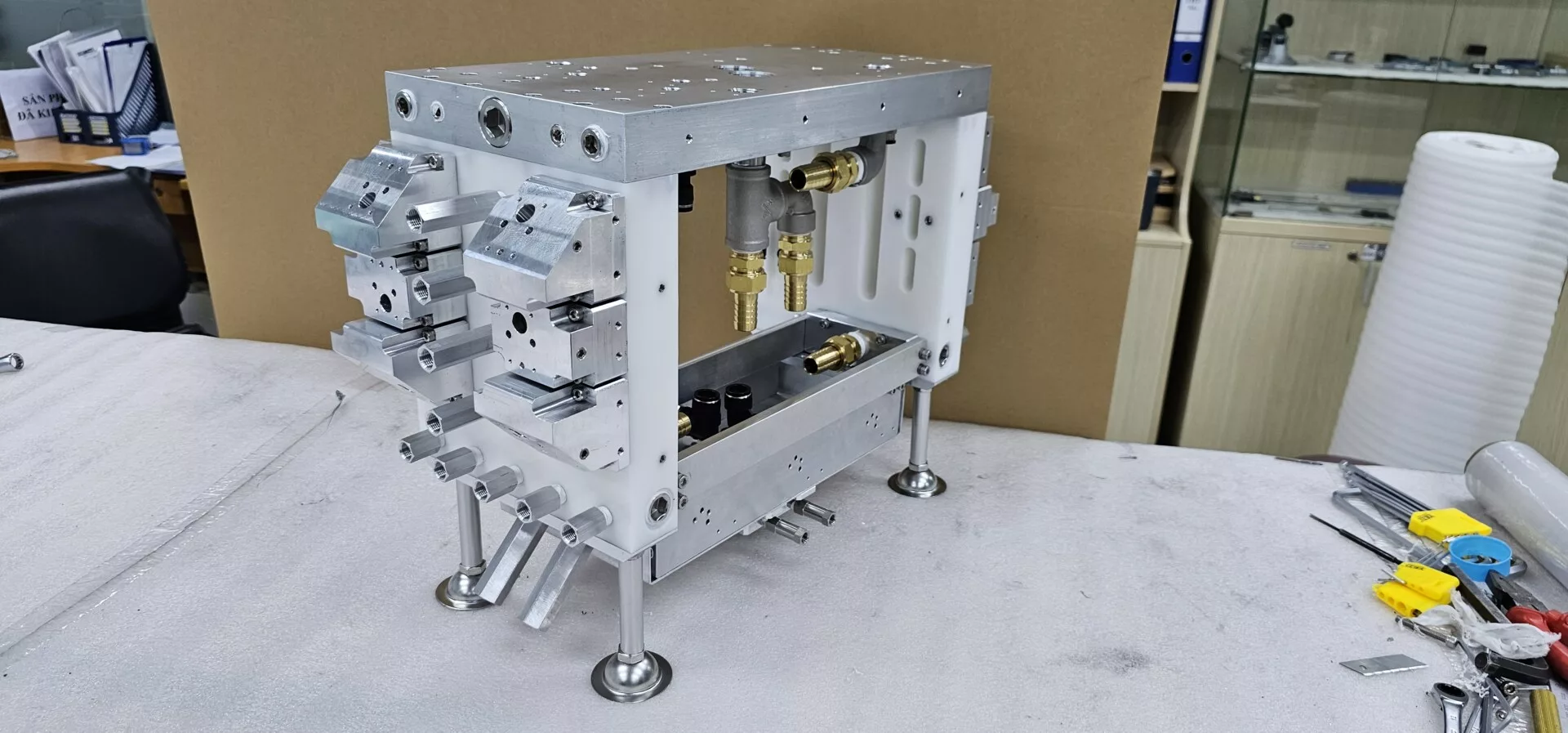

Jigs and fixtures are essential elements in the manufacturing ecosystem. In simple terms, a jig guides the cutting or machining tool, while a fixture securely holds the workpiece in place during operations. Combined, these tools significantly reduce human error, increase production speed, and consistently maintain product quality — all while minimizing rework and material waste.

In industries where even a slight deviation can lead to functional or safety issues, having a tailored workholding design becomes vital. From CNC machining centers to manual assembly lines, jigs and fixtures optimize workflow by allowing seamless part orientation, repeatability, and tooling accessibility.

Key Benefits of Innovative Workholding Design

- Improved Accuracy: Eliminates variability in part positioning and machining operations.

- Reduced Cycle Time: Speeds up manufacturing by streamlining setup and handling.

- Consistent Quality: Ensures dimensional precision and high repeatability across production runs.

- Operator Safety: Enhances safety by securely clamping parts, reducing unexpected movement.

- Scalability: Supports small-batch and high-volume production with minimal adjustments.

Designing Jigs and Fixtures for Precision Machining

Successful jigs and fixtures design requires an intricate understanding of the part geometry, machining process, tool paths, and tolerance requirements. At IDEA’s Machine Design and Drafting Services, designers deploy advanced CAD tools, finite element analysis (FEA), and simulation techniques to engineer robust and ergonomic workholding solutions.

Design considerations typically include:

- Locating and Clamping: Proper locator design to ensure repeatability and precise orientation without deformation.

- Tolerance Stack-up: Analyzing dimensional chains to prevent cumulative errors.

- Ease of Use: Quick-release mechanisms or modular setups to simplify operator interaction.

- Material Selection: Using durable alloys, composites, or even 3D-printed parts based on the application environment.

Applications Across Industries

The requirements for jigs and fixtures vary based on application. In aerospace and automotive, precision and robustness are paramount, while in electronics and medical device manufacturing, micro-level accuracy is critical.

Some common applications include:

- Drilling and tapping guides for structural components

- Precision welding fixtures for automotive chassis

- Inspection jigs for quality control

- Assembly fixtures for circuit board integration

Partners like Che Tao May IDEA offer customized solutions that align with specific industry challenges, enhancing final product reliability and performance.

Adopting Smart Fixture Technologies

Modern manufacturing integrates IoT and sensor-based systems into workholding design for smart monitoring and adaptive machining. Real-time data such as clamping pressure, vibration, and temperature allows operators to detect anomalies and perform predictive maintenance, which is increasingly vital in Industry 4.0 operations.

Suppliers like IDEA Techmart are leading this transformation by offering advanced components and systems that support automation-ready jigs and fixtures, reducing labor costs and maximizing uptime.

Partner with IDEA for Optimized Jigs and Fixtures Design

From concept to implementation, IDEA Group Vietnam combines mechanical engineering expertise and industry insight to develop workholding systems that meet the highest standards of precision machining. Our collaborative approach ensures that each jigs and fixtures design aligns with your production goals, budget, and delivery timelines.

Whether you’re launching a new assembly line or upgrading existing workstations, IDEA helps bring your vision into motion. Visit our full range of Machine Design and Drafting Services to learn how we can enhance your manufacturing performance through smarter fixture design.

Ready to take your workholding design to the next level? Partner with IDEA — your trusted Vietnamese engineering firm in precision jigs and fixtures design and industrial solutions.