In modern industrial engineering, finite element analysis is transforming how machines are designed, tested, and optimized. By simulating structural behavior under various conditions, engineers can predict performance, identify potential weaknesses, and refine prototypes before manufacturing begins. This capability saves time, reduces costs, and enhances the overall quality of mechanical systems—making FEA software indispensable in today’s competitive manufacturing landscape.

What is Finite Element Analysis (FEA)?

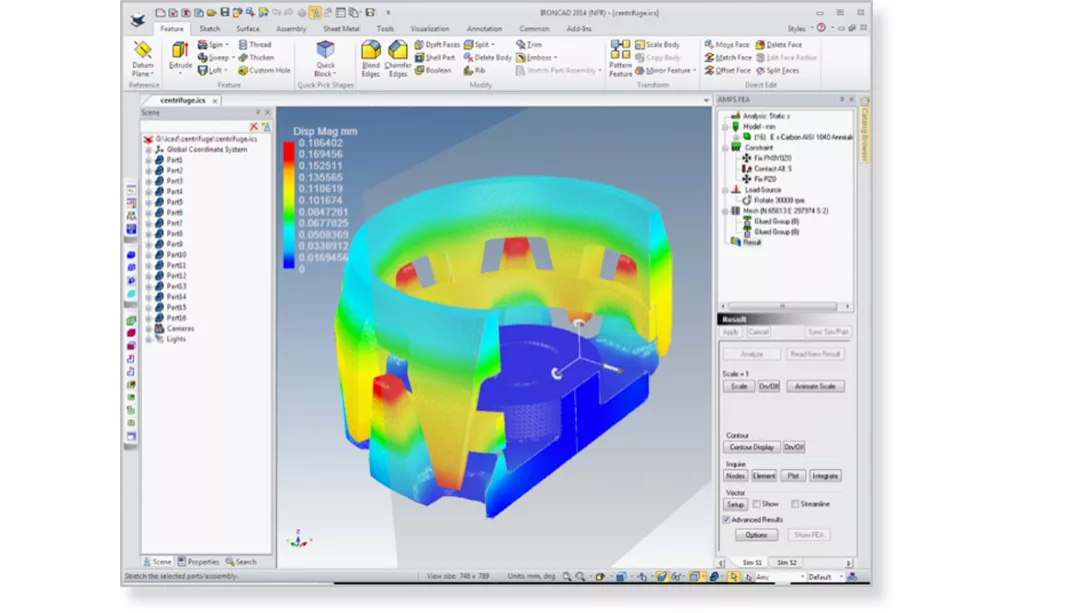

Finite element analysis is a computational method used to predict how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. By dividing a structure into millions of finite pieces, or “elements,” and solving complex equations across them, FEA provides detailed insights into a component’s behavior under stress.

Engineers commonly apply FEA in applications such as:

- Mechanical stress testing in structural components

- Thermal analysis of machine and electronic assemblies

- Dynamic simulations of moving parts

- Fatigue and failure testing for critical load-bearing systems

The Role of Structural Simulation in Machine Design

Structural simulation plays a vital role in modern machine design, enabling engineers to analyze, iterate, and improve concepts long before physical prototypes are produced. With accurate simulations, teams can evaluate structural integrity without expensive field testing, ensuring compliance with performance and safety standards.

Combining FEA software with CAD tools streamlines the design process and offers benefits such as:

- Increased design precision

- Early detection of stress concentration zones

- Reduced prototyping cycles

- Enhanced product reliability and lifespan

At IDEA’s machine design and drafting services, we integrate structural simulation at every design phase to deliver highly efficient, durable, and cost-effective mechanical solutions.

Key Benefits of Using FEA Software

Utilizing advanced FEA software offers companies the following strategic advantages:

- Accelerated Development: Cut down design cycles by validating concepts digitally.

- Cost Reduction: Minimize material waste through precise simulations and optimal design iterations.

- Improved Quality: Ensure machines meet stringent performance standards before physical assembly.

- Design Optimization: Explore “what-if” scenarios to refine configurations and extend equipment life.

Leading engineering platforms such as Chetaomay Idea and Idea Techmart leverage these tools to deliver world-class engineered systems for industrial, automation, and manufacturing sectors.

Applications of Finite Element Analysis in Industrial Sectors

Across industries, finite element analysis is key to validating and optimizing complex engineering systems. From automotive and aerospace to heavy machinery, its impact is far-reaching:

- Manufacturing Equipment: Ensures structural integrity of presses, conveyors, and automation systems.

- Automotive Components: Validates the safety and efficiency of engine parts, suspension systems, and crash zones.

- Packaging Machinery: Simulates repetitive stress on mechanical arms and gears to predict wear.

- Energy Systems: Optimizes HVAC structures, turbine models, and renewable energy solutions.

By providing predictive insights, structural simulation directly contributes to increased operational efficiency and reduced maintenance costs.

Partner with IDEA for Precision-Engineered Solutions

With decades of experience in mechanical design and integrated engineering, IDEA Group Vietnam is a reliable partner for companies looking to drive innovation through simulation and digital design. Our experts deploy the latest FEA tools to ensure that every machine we develop is structurally sound, cost-effective, and built for longevity.

Whether you’re developing new equipment or optimizing existing components, our team is equipped to support your project from concept through manufacturing. Let us help you bring your ideas to life with proven design principles and advanced structural simulation techniques.

Explore the full potential of finite element analysis with IDEA—your trusted partner in industrial machine design and structural innovation.