Design for manufacturability (DFM) in CNC machining plays a critical role in streamlining production processes, reducing costs, and achieving precise, high-quality parts. By incorporating manufacturing considerations during the design phase, engineers can avoid common mistakes that lead to delays, excessive material waste, and increased post-processing. A thoughtful DFM approach ensures efficiency without compromising part functionality or tolerances—especially in high-precision sectors such as aerospace, automotive, and industrial machinery.

Understanding Design for Manufacturability in CNC Machining

Design for manufacturability in CNC machining refers to optimizing part geometry, material selection, and tolerances to align with the capabilities and limitations of CNC machines. This strategic design process minimizes production challenges and enables higher repeatability, faster lead times, and reduced costs per unit.

Core Principles of DFM in CNC Processes

Integrating smart design principles helps optimize manufacturing throughput. Below are the key concepts to consider when drafting parts for CNC machining:

- Simplify geometries: Avoid unnecessary complexity such as deep cavities or intricate internal features that increase machining time and tool wear.

- Select machinable materials: Materials like aluminum, mild steel, and certain plastics provide better machinability and reduce tool wear.

- Design with tooling access in mind: Ensure all features are reachable by standard end mills or turning tools.

- Standardize hole sizes: Design holes using standard drill bit sizes to speed up machining and reduce custom tooling.

- Minimize the number of setups: Design features that allow multiple operations to be performed in one setup to reduce repositioning errors.

The Importance of Tolerances in DFM

A critical area in design for manufacturability is the specification of tolerances. Overly tight tolerances can drive up costs and machining time unnecessarily. Engineers must balance form, function, and feasibility when applying dimensional tolerances to CNC-machined parts.

Types of Tolerances in CNC Machining

- General tolerances: Common for non-critical surfaces; they require standard accuracy levels of ±0.1 mm or more.

- Tight tolerances: Applied to components demanding precise fits; often range between ±0.005 to ±0.01 mm, but require more time and higher tooling quality.

- Geometric dimensioning and tolerancing (GD&T): Used to control form, orientation, and location with higher precision in complex designs.

When in doubt, it’s advisable to consult with a CNC tooling expert or leverage digital simulation tools during the design process. Resources such as Che Tao May IDEA provide valuable insights on tool paths and tolerance management in real-time machining environments.

Common DFM Mistakes in CNC Machining

Even experienced engineers can overlook design choices that make CNC machining less efficient. Common pitfalls include:

- Specifying ultra-tight tolerances throughout instead of assigning them only to critical features.

- Ignoring tool radius considerations, especially when designing internal corners with 90° sharp edges.

- Designing thin walls that may chatter or deform during machining operations.

- Failing to account for material behavior such as thermal expansion or stress-relieving needed post-machining.

Prevention starts with collaboration between design and manufacturing teams. Services like those offered at IDEA’s machine design and drafting department can help bridge this gap for more efficient builds.

Benefits of a DFM-Centric Approach

Companies that integrate design for manufacturability in CNC machining into their workflows unlock significant advantages:

- Reduced manufacturing lead time and cost per part

- Improved part consistency and reduced reworks

- Greater alignment between design intent and production output

- Optimized use of CNC equipment capabilities

These advantages translate into a faster route to market and improved competitive positioning.

Tools and Resources to Improve DFM

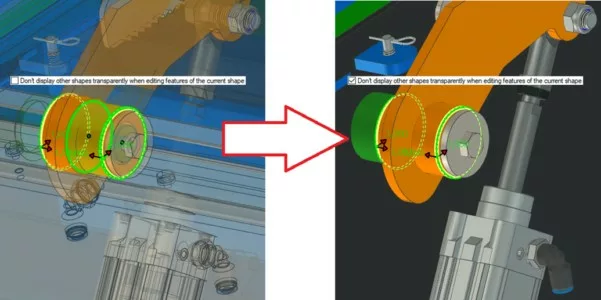

To make DFM successful, leverage CAD/CAM tools that simulate manufacturing feasibility and analyze tolerances. Cloud-based platforms and digital twins also aid validation. Technical marketplaces such as IDEA Techmart offer access to verified parts, materials, and toolpath libraries to support efficient CNC programming and prototyping.

Final Thoughts on Design for Manufacturability in CNC Machining

Implementing design for manufacturability in CNC machining ensures optimal part quality, reasonable tolerances, and cost-effective production. By focusing on DFM strategies from the early design stages, companies can avoid downstream issues, improve repeatability, and achieve greater machining efficiency.

Collaborate with IDEA Group—your trusted partner in Vietnam—to turn your designs into real-world solutions with precision, speed, and cost-efficiency. Leverage our extensive experience in industrial machine design and manufacturing to bring your next project to life, smarter and faster.