What is Deep Hole Drilling Technology?

Deep Hole Drilling Technology is an essential technique in precision machining, used to create high-accuracy cylindrical holes that exceed standard depth-to-diameter ratios. This process is widely applied in aerospace, automotive, medical devices, and mold manufacturing.

In this article, we explore five key deep hole drilling methods, their applications, advantages, and limitations in precision engineering.

I. How Many Drilling Methods Exist in Precision Machining?

Let’s explore the various techniques used in precision deep hole machining.

Drilling is a cutting process used to create cylindrical holes, categorized into shallow hole drilling and deep hole drilling. In the precision machining industry, hole machining plays a crucial role, as many mechanical components and technical parts require highly precise and complex hole structures. Below are some of the most commonly used drilling methods in precision machining:

1. Lathe Drilling

Lathe drilling is one of the most fundamental and widely used methods. It involves machining rotational parts, often with a central hole. The advantages of this method include:

- Ability to achieve deep cutting depth

- Fast machining time

- Low operational costs

However, lathe drilling has some limitations, such as its inability to machine non-symmetrical holes or achieve extremely high precision due to centrifugal forces and the rotational nature of the workpiece.

2. Drill Press Machining

Drill presses are widely used in precision machining due to their simplicity, low cost, and ease of operation. However, there are some disadvantages:

- Low drilling speed, resulting in longer machining time

- Surface quality of the hole is not optimal

- Drill bits are usually standardized, limiting flexibility in applications

3. Wire EDM Hole Machining

Wire Electrical Discharge Machining (Wire EDM) has become a common method, especib for machining with an accuracy of 0.03–0.1mm and flexible hole diameters. However, the drawbacks include:

- High cutting costs

- Surface roughness remains relatively high

4. Boring Machine Drilling

Boring machines are used to achieve high surface finish and precision. However, due to their low rotational speed, machining time is longer. As a result, this method is primarily applied to components requiring high surface quality rather than high production volume.

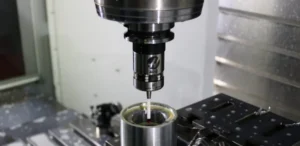

5. CNC Drilling

CNC drilling is the most advanced and widely used method in the precision machining industry. CNC machines enable deep hole drilling with exceptional precision and excellent surface quality. The CNC program controls cutting tools to create deep holes with the desired dimensions and geometries, optimizing the process and ensuring uniformity. This method is highly efficient, flexible, and time-saving, making it ideal for high-precision, large-scale production.

II. Deep Hole Drilling Methods: Diversity and Applications in Precision Machining

In precision engineering, deep hole drilling is essential for machining complex components requiring high precision and smooth surface finishes. Choosing the appropriate method directly impacts the final product’s quality and efficiency. Below are some of the most commonly used deep hole machining techniques:

1. Conventional Cutting Process

This is the most widely used deep hole drilling technique. It is performed using lathes, milling machines, or grinding machines to remove material and create holes with precise dimensions and shapes. Skilled operators must ensure accuracy and surface quality during the machining process.

2. Electrochemical Machining (ECM)

This method is suitable for deep holes requiring high precision. Electrochemical machining removes material through electrolytic dissolution, where an electric current is used to dissolve metal in an electrolyte solution. This technique allows for high-precision deep holes with excellent surface finishes but is less commonly used due to its complexity and specialized equipment requirements.

3. Plastic Deformation Machining

This method is applied for small-diameter, deep holes. The process is based on the plastic deformation properties of metal, where the material is heated to forging temperature and shaped under force to create deep, high-precision holes with smooth surfaces.

Conclusion

The above methods are widely used in deep hole machining within the precision engineering industry. Selecting the right technique depends on specific product requirements, including precision, surface finish, machining time, and production costs.