A major Japanese company that designs and manufactures conveyor systems.

A major Japanese company that designs and manufactures conveyor systems.

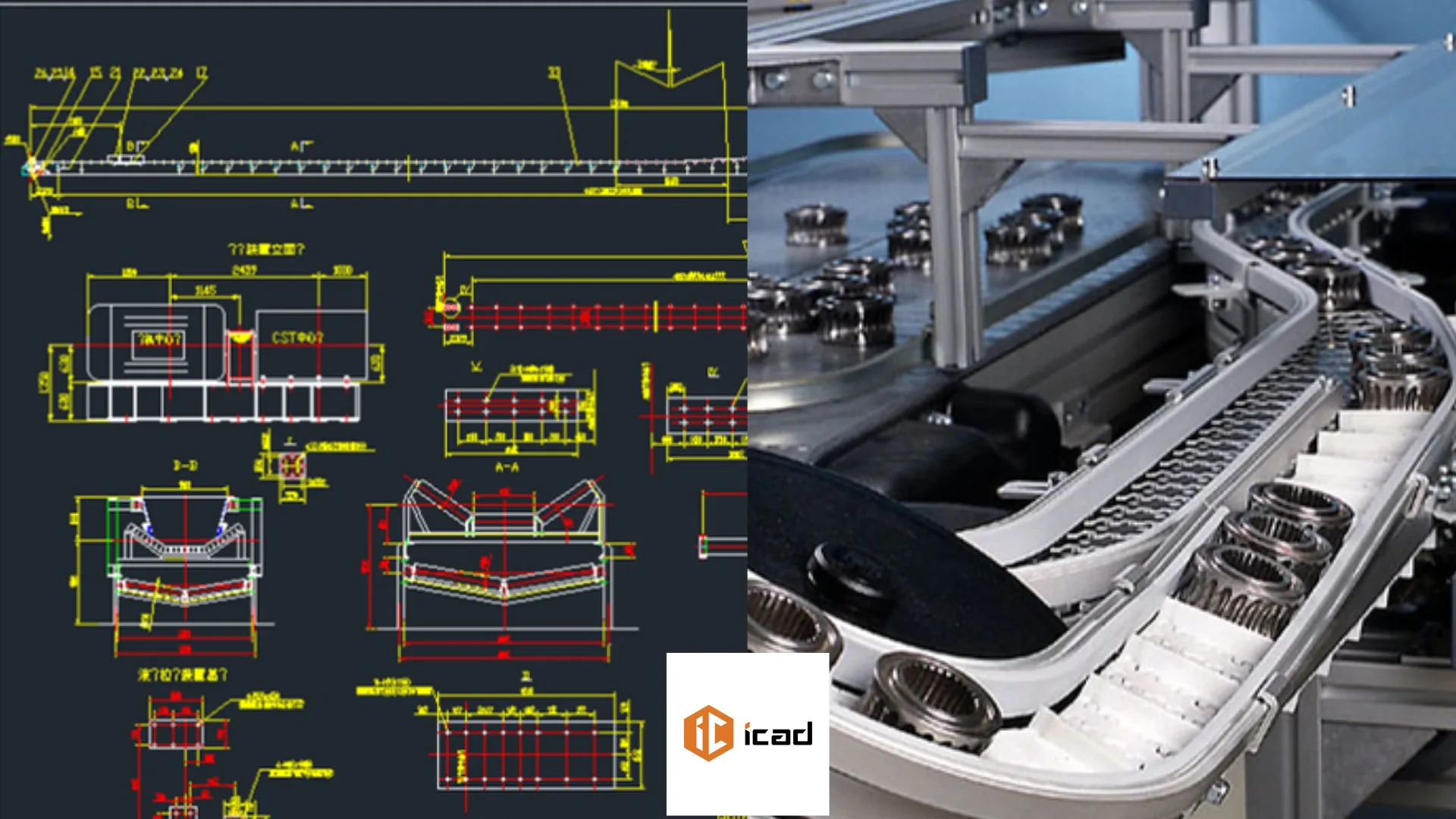

Convert drawings to 2D CAD for 10,000 conveyor models

The project was completed three months early, resulting in cost savings of 3 million yen and increased productivity.

A leading Japanese conveyor manufacturer needed to convert 10,000 product drawings to 2D CAD using ICAD software. IDEA Technology provided a dedicated team of CAD engineers, optimizing workflows, ensuring high precision, and accelerating project completion while reducing costs by 3 million yen.

A major conveyor manufacturing company in Japan (e.g., Makitech) faced the challenge of completely migrating the design data of 10,000 product models to ICAD software. These models included parts and optional components, which not only required a significant workload but also demanded high precision to optimize both the design and manufacturing processes.

IDEA Technology provided a dedicated team of six design engineers, who worked full-time on this project for three years. The team closely collaborated with the client, adopting a phased approach to systematically advance the work while flexibly adjusting designs based on client requirements. Additionally, weekly review meetings were held to ensure quick feedback and seamless communication. The client also visited Vietnam to directly guide the team, enhancing mutual understanding and alignment on the work processes.

The project began in the first year with three team members, focusing on establishing the workflow foundation and familiarization. Subsequently, internal training sessions were conducted, and the team expanded to four members in the second year, then five, and finally six members. This gradual expansion approach allowed for optimized work processes and continuous skill development among team members.

The project was completed three months ahead of schedule, achieving a cost reduction of approximately 3 million yen for the client. The traced CAD drawing data enabled the client to seamlessly provide standardized design documentation to machine manufacturers and production partners, enhancing design and production flexibility while significantly improving overall productivity.

Through CAD design outsourcing, IDEA Technology successfully addressed both manpower and time constraints, offering clients a competitive advantage. By building an advanced CAD drawing trace system, we not only achieved cost savings but also enhanced the manufacturing process, contributing to the client’s sustainable business growth.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.