The demand for manufacturing outsourcing of the industrial mechanical industry market is increasing day by day. In addition, products are required to have high precision and to process large quantities in a short time. To meet that requirement, businesses have been investing in CNC milling machines with modern and advanced technology. The machine not only helps products to be processed with high standard quality, but also brings great productivity thanks to the automatic operation process through the computer control system.

So which CNC milling machine should businesses choose? What are the different types? The following article will help you answer and classify the popular CNC milling machines today. Thereby businesses can learn and make investment decisions more effectively.

I.Classification of CNC milling machines by structure

1.CNC vertical milling machine

The CNC vertical milling machine has a spindle structure that is perpendicular to the table in the vertical direction. The machine is controlled by the CNC system programmed on the computer.

When operating, the spindle containing the cutter usually moves up and down in the Z direction. The table moves back and forth in the X, Y horizontal directions.

The advantages of vertical milling machines are short machining time, fast cutting speed, high accuracy and reduced installation time. There are types such as 3-axis, 4-axis, 5-axis CNC vertical milling machines… The more axes the structure, the more complex the machine can process and the higher the cost of the machines. The most common type of CNC vertical milling machine in production today is the 3-axis CNC vertical milling machine.

The machine can process on flat surfaces, slots, grooves, etc. It can process a variety of materials such as metal, aluminum, iron, steel, etc.

2.CNC horizontal milling machine

The CNC horizontal milling machine has a spindle structure parallel to the table in the horizontal direction. The machine has many advantages over traditional milling machines because the machine is controlled by the CNC system.

Through the integrated control system on the machine, the operator can easily observe the machining process. Ensure accurate machining and save on labor costs because you don’t have to hire many operators.

Horizontal milling machines have a larger table than vertical milling machines, so they can process larger and heavier products. The material removal rate is fast, to save machining time and push the product to market.

The machine is often used to design molds, process machine blocks, or process gearboxes, engine boxes, etc.

3.CNC Bed Milling Machine

The CNC bed milling machine is a special form of the CNC vertical milling machine. The table of the large CNC bed milling machine is mounted on a solid base. Thanks to this special structure, the machine is very suitable for processing large sheet materials or large-sized parts.

When operating, the table moves vertically, perpendicular to the main axis. The main axis moves more flexibly, translating back and forth and up and down in the other 2 directions (X, Z).

The machine can process details on many different materials: metal, non-metal, iron, steel… The details are often processed such as car head assemblies, crankshafts, large diameter steel pipe blocks. , gears, flywheels, machine parts, tanks, super-long, super-weight machine frames,

II.CNC milling machine classification by number of axes

1.3 axis CNC milling machine

The machine has a structure of 3 main axes, X, Y, Z arranged depending on the machine design. The most common is the type with the table moving in the X, Y axes. Combined with the movement in and out of the workpiece of the main axis in the Z direction.

The machine produces a variety of materials such as metals (steel, copper, aluminum, …), is applied in many industries such as mechanical manufacturing, aerospace, machine parts, …

2.4 axis CNC milling machine

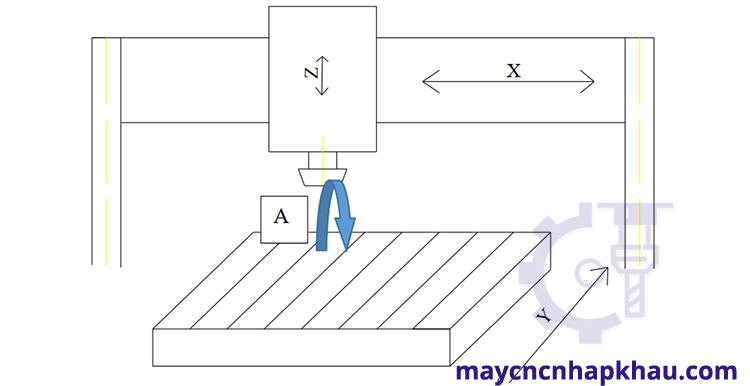

On a 4-axis CNC milling machine, the overall structure is the same as that of a 3-axis milling machine. In addition, the machine is equipped with a turntable and A-axis, which can perform more operations.

The machine is added with the A axis to rotate the X axis. The addition of a 4th axis allows the workpiece to move, rotate, and flip at will. The machine can machine 4 sides of the part to be machined by flipping the workpiece. During operation, the workpiece on the table moves along the X, Y axes; The main axis moves along the Z axis up and down. Axis A holds the workpiece and helps it to rotate to produce the product of the desired shape.

With an additional A-axis construction for more uses. The machine is capable of cutting workpieces at multiple angles (4 sides). Workpiece placement or zero reset is simpler than with 3-axis CNC milling machines. The machine is used to process molds; automotive, mechanical, aviation, marine, medical equipment, technology…

3.5 Axis CNC Milling Machine

The 5-axis CNC milling machine has the same basic structure as the 4-axis CNC milling machine. The special feature of the machine is that it is integrated with a B axis. This structure makes the processing machine more flexible. In addition to automatic movements in the X, Y and Z axes like 3-axis CNC milling machines. 4 axis CNC milling machine can choose 2 out of 3 rotary axes (A, B, C) to use. The A, B and C axes perform 180° rotation around the X, Y and Z axes respectively.

The machine is used in the automotive, aerospace and boat industries.

At IDEA, we specialize in receiving precision mechanical processing, designing drawings of products and components with high precision for leading enterprises in Japan, the US,… All your problems we have. are all solvable, please contact IDEA immediately.

Article reference source: maycncnhapkhau.com