In today’s fast-paced manufacturing environment, companies are turning to automated conveyors as a game-changing solution for optimizing material handling and promoting smart transportation. These advanced systems not only streamline internal logistics but also substantially increase factory efficiency. From reducing labor costs to minimizing production downtime, automated conveyor systems are at the forefront of modern industrial automation strategies.

What Are Automated Conveyor Systems?

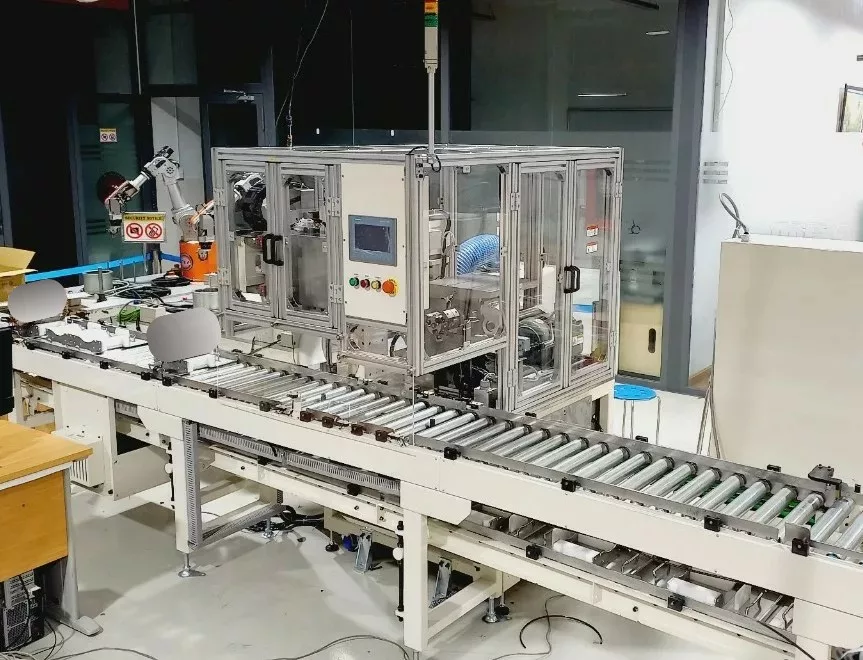

Automated conveyor systems are mechanized transport solutions designed to move goods, parts, or materials throughout a production or distribution facility with minimal human intervention. Integrated with sensors, programmable logic controllers (PLCs), and smart software, these systems enable continuous, reliable movement tailored to industrial requirements. They are a crucial part of any advanced manufacturing setup.

Key Benefits of Automated Conveyors

Implementing automated conveyance offers numerous operational and financial benefits. Here’s how these systems enhance productivity and competitiveness:

1. Improved Factory Efficiency

- Accelerate production cycles with faster, uninterrupted material flow.

- Reduce human error and variability in operations.

- Real-time data collection enables predictive maintenance and process optimization.

2. Enhanced Smart Transportation and Logistics

Modern automated conveyors integrate with IoT-enabled technologies to form a complete smart transportation ecosystem. This allows seamless product traceability, load optimization, and intelligent workflow management.

- Real-time tracking and monitoring of goods inside the facility.

- Optimized routing algorithms to reduce bottlenecks.

- Integration with ERP and warehouse systems for end-to-end connectivity.

3. Lower Operational Costs

Though the initial investment in automation may seem significant, the long-term savings are substantial. Lower labor costs, reduced downtime, and energy-efficient operation all contribute to a strong return on investment.

- Minimize reliance on manual labor for material handling.

- Reduce workplace injury risks and associated insurance costs.

- Automated stop/start functions to conserve energy during non-peak periods.

4. Scalability and Flexibility

Automated conveyor systems provide high scalability, making them suitable for evolving manufacturing needs. Modular designs allow for expansions or adjustments without a complete overhaul.

- Flexible configurations for future process changes.

- Adaptable to different product sizes and industries.

- Integration-ready with robotics and other automation tools.

Applications Across Multiple Industries

From automotive assembly to food packaging and electronics, automated conveyors are employed across various sectors. These systems are critical to companies aiming to adopt cutting-edge industrial automation methods for global competitiveness.

Industries Benefiting from Automated Conveyors

- Electronics assembly lines for precision transport.

- Pharmaceuticals for cleanroom-compliant movement of products.

- Food and beverage for hygienic material handling.

- Automotive for just-in-time part delivery.

- Logistics and warehousing for order fulfillment and sorting.

Why Choose IDEA for Conveyor System Implementation?

At IDEA, we specialize in providing tailored automation solutions, including the design and integration of reliable and efficient conveyor systems. Our machine design and drafting services ensure each system is engineered to meet precise operational needs, optimizing both performance and return on investment.

Our team brings expertise in mechanical design, smart automation integration, and site implementation across a range of manufacturing industries in Vietnam and beyond. With a customer-first approach, we ensure technology is aligned with your business goals.

Automated conveyors are no longer a luxury—they’re a necessity for businesses aiming to thrive in the era of smart transportation and intelligent production. By adopting these systems, you can dramatically improve factory efficiency, deliver consistent product quality, and gain a competitive edge in your industry.

Ready to upgrade your production line with automated conveyors? Partner with IDEA today and take the first step toward flexible, future-ready manufacturing.