Manufacturing – Electronics Component Fabrication and Assembly

Manufacturing – Electronics Component Fabrication and Assembly

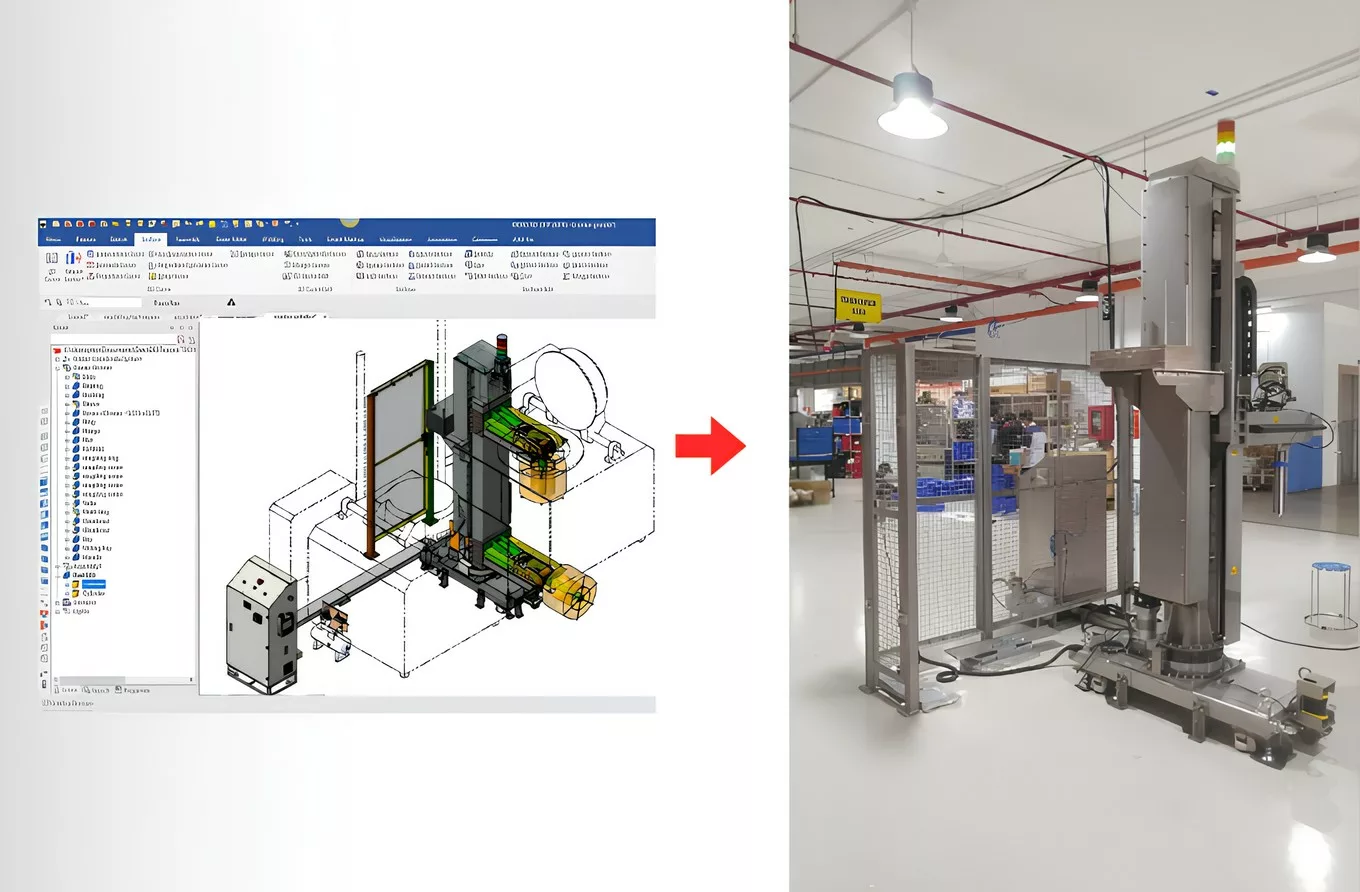

Automated Bobbin Transport Solution

“The automation system from IDEA Group has enabled us to transport 50Kg bobbins into the drying oven quickly, safely, and continuously, meeting high production demands while maintaining quality. The process is now fully automated, eliminating the risk of accidents and reducing manual labor. This solution not only enhances production efficiency but also provides sustainable value for the business. IDEA Group is a trusted partner in automation.”

The automated Bobbin transport solution in the electronics industry is designed to enhance efficiency and ensure safety in the production process of Fabric Core products. With the requirement to transport Bobbins weighing up to 50kg, containing flexible circuits into the drying oven, optimizing this transport process is a top priority to minimize risks and improve production time.

A leading company in the electronics sector sought to improve its production efficiency and safety for the manufacturing of Fabric Core products. These products require the transportation of heavy Bobbins, which hold flexible circuits, into the drying oven. The Bobbins can weigh up to 50kg, making the transport process particularly challenging. Ensuring the safe movement of these heavy components while maintaining production speed is of paramount importance to the company. Therefore, optimizing this transport process became an essential focus, aiming to reduce potential risks and enhance production timelines without compromising on quality.

Transporting Bobbins with a weight of 50kg each presented several challenges, particularly in adhering to the strict safety standards required for handling such heavy items. Historically, the manual transport process was labor-intensive, which led to a range of issues including inconsistent handling, high labor costs, and the potential for accidents in the workplace. The manual handling of Bobbins created risks not only for operators but also for the quality of the product, as improper handling could damage the delicate circuits inside. In addition, meeting the increasing demand for high-volume production while maintaining safety and quality standards was becoming increasingly difficult. The company required an Automation Solution to improve both the safety and efficiency of the Bobbin transport process.

We implemented an automated lifting and transport system meeting Safety PLd, Cat. 3 standards. This system was specifically designed to meet the safety requirements for transporting 50kg Bobbins. Key features include:

Following the implementation of the automated Bobbin transport solution, the company saw a significant improvement in several key areas.

With the automated Bobbin transport system in place, the company was able to scale its production capabilities and meet growing market demand while maintaining the highest standards of safety, performance, and product quality. This transformation has provided the company with a solid foundation for continued growth, allowing it to maintain its competitive edge in the electronics market. The successful implementation of this Automation Solution positions the company for long-term success and expansion.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.