Automation in machine manufacturing is revolutionizing how industrial systems are designed, built, and operated. With rapid advancements in smart technologies and increasing demand for efficiency, industries across the globe are embracing automated solutions to enhance productivity, ensure quality, and reduce operational costs. One transformative innovation making waves in this sector is the 5032 automation protocol, which contributes to streamlined communication between machines and optimized production workflows.

What is 5032 in Automation?

The term 5032 refers to a specific protocol or system framework often used in machine automation to enable seamless interface integration and data exchange. It influences programming standards and helps machines interpret and execute commands more effectively. In modern manufacturing, adopting systems based on 5032 enhances compatibility across hardware and software interfaces, paving the way for smart and connected operations.

Key Benefits of Automation in Machine Manufacturing

Implementing automation not only boosts operational efficiency but also positions businesses for long-term success. Here are the core benefits:

- Increased Production Speed: Automated systems can operate continuously without fatigue, significantly increasing throughput.

- Improved Product Quality: Automation enhances precision and repeatability, reducing the margin of human error.

- Lower Operational Costs: While initial investments can be high, automation saves money over time through reduced labor costs and material waste.

- Enhanced Worker Safety: Automation takes over dangerous or repetitive tasks, minimizing the risk of workplace injuries.

- Real-Time Monitoring & Control: With protocols like 5032 in place, manufacturers can remotely monitor and adjust parameters for optimal performance.

Emerging Trends Shaping the Future of Automation

Automation in manufacturing continues to evolve, driven by digital transformation and sustainability goals. Firms leveraging the latest technological developments are staying ahead of the curve. Below are several key trends making an impact:

1. Integration of IIoT and Smart Sensors

The Industrial Internet of Things (IIoT) enables machines to communicate in real-time, providing valuable insights into performance and reliability. When integrated with smart sensors and standardizations like 5032, manufacturers gain a powerful edge in predictive maintenance and real-time optimization.

2. AI and Machine Learning

Artificial Intelligence is transforming how manufacturers make decisions. AI-driven analytics assist in forecasting demand, optimizing supply chains, and improving quality control mechanisms. Visit Che Tao May IDEA to explore how advanced automation is applied in real-world machinery systems.

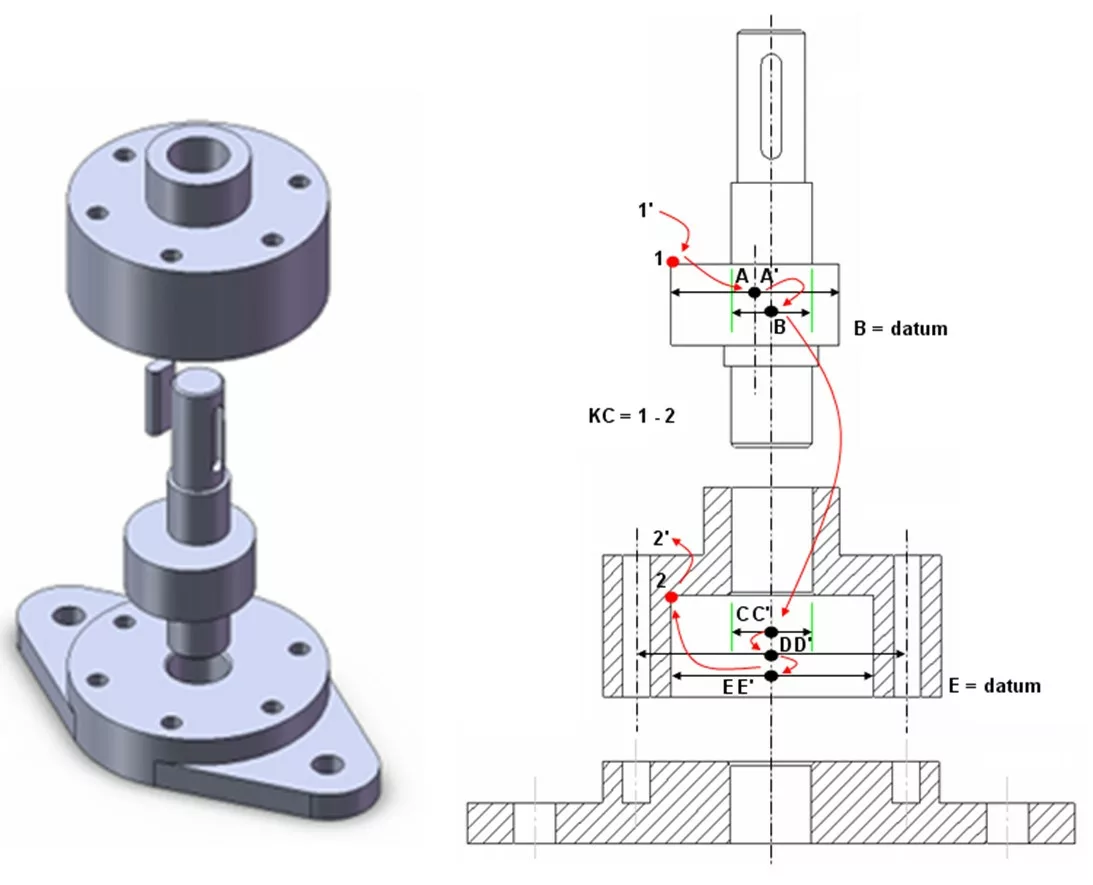

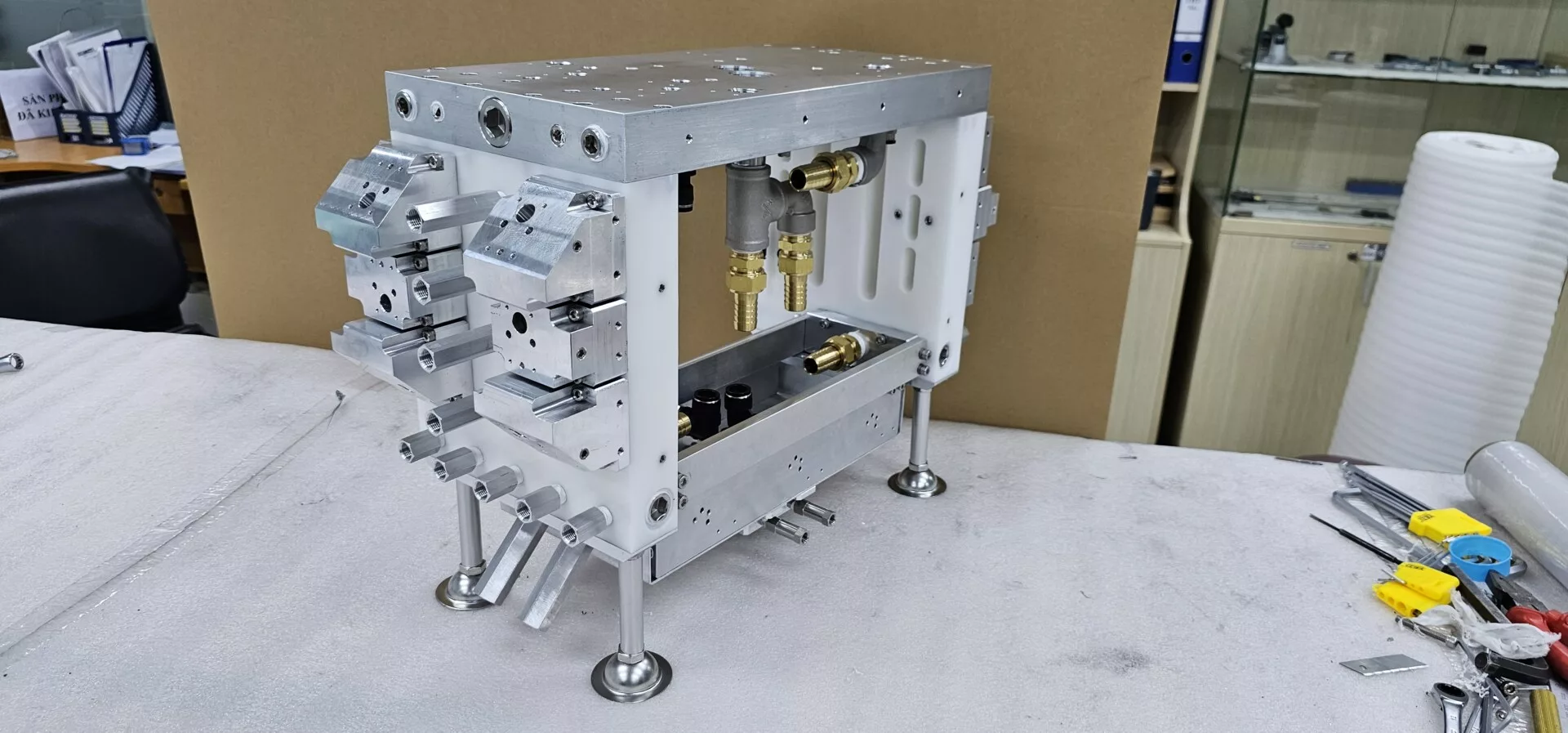

3. Modular Machine Design

Automation-friendly machine design now emphasizes modularity and scalability. This approach allows easier upgrades and customization, ideal for businesses operating in dynamic markets. For customized design solutions, check out IDEA’s machine design and drafting services.

4. Sustainability and Energy Efficiency

Modern manufacturing prioritizes systems that reduce energy consumption and minimize waste. Smart automation enabled by protocols like 5032 supports zero-defect manufacturing and responsible resource usage, aligning with global sustainability standards.

Why Choose IDEA for Machine Automation?

With a strong background in industrial automation and machine manufacturing, IDEA delivers turnkey solutions tailored to your business needs. As a trusted partner, we offer cutting-edge technologies, including advanced 5032-compatible systems, and comprehensive engineering services to streamline your production process.

Our commitment to quality, innovation, and continuous improvement makes us the go-to choice for manufacturers in Vietnam and beyond. Whether you’re upgrading an existing system or building a new fully-automated line, IDEA brings the expertise you need. Learn more about available automation products at IdeaTechMart.

Partner with IDEA for Automation Success

As automation technologies continue transforming machine manufacturing, it’s crucial to collaborate with experienced partners who understand evolving standards like 5032. IDEA stands at the forefront of industrial innovation, delivering efficient, scalable, and future-ready automation solutions. Contact IDEA today to turn your automation vision into a reality.