In the highly competitive world of precision machining, efficiency, accuracy, and repeatability are paramount. One of the most critical factors influencing these outcomes is the optimized use of jigs and fixtures. These tools form the foundation of effective workholding design, ensuring that every part is consistently manufactured to the tightest tolerances. As machining operations become increasingly automated, the demand for innovative jigs and fixtures has never been greater.

What Are Jigs and Fixtures?

Jigs and fixtures are essential components in manufacturing, particularly in precision machining. While both serve to hold, support, and locate the workpiece, they have distinct functionalities:

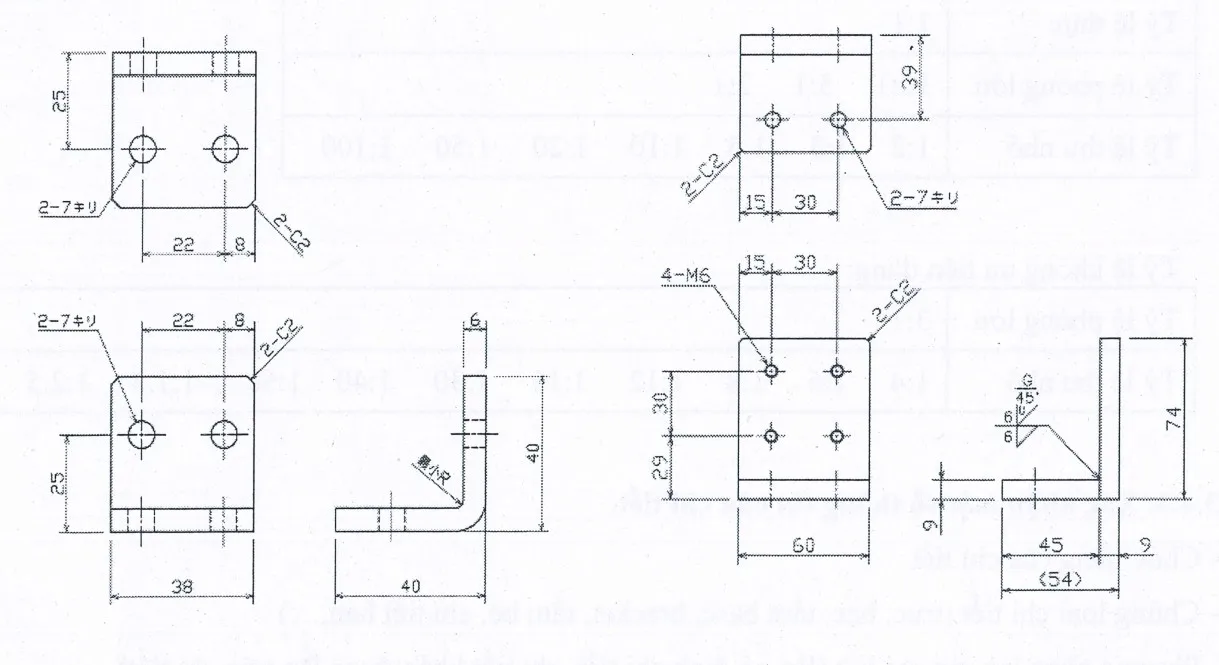

- Jigs guide the cutting tool during machining operations, ensuring accuracy without the need for additional measurements.

- Fixtures keep the workpiece securely in place during the process, allowing for consistency and repeatability.

In high-performance manufacturing environments, an effective workholding design not only maintains dimensional accuracy but also minimizes human error and cycle time.

Importance of Jigs and Fixtures in Precision Machining

Precision machining requires high levels of repeatability and accuracy to meet tight tolerance specifications. Jigs and fixtures contribute to this by:

- Enhancing setup consistency and reducing alignment time across multiple components

- Improving production efficiency and throughput

- Increasing operator safety through secure clamping systems

- Maintaining uniform quality across all production batches

These workholding designs reduce production costs and rework by ensuring that every machined component meets the desired standards from the first cut.

Custom Workholding Design for Advanced Applications

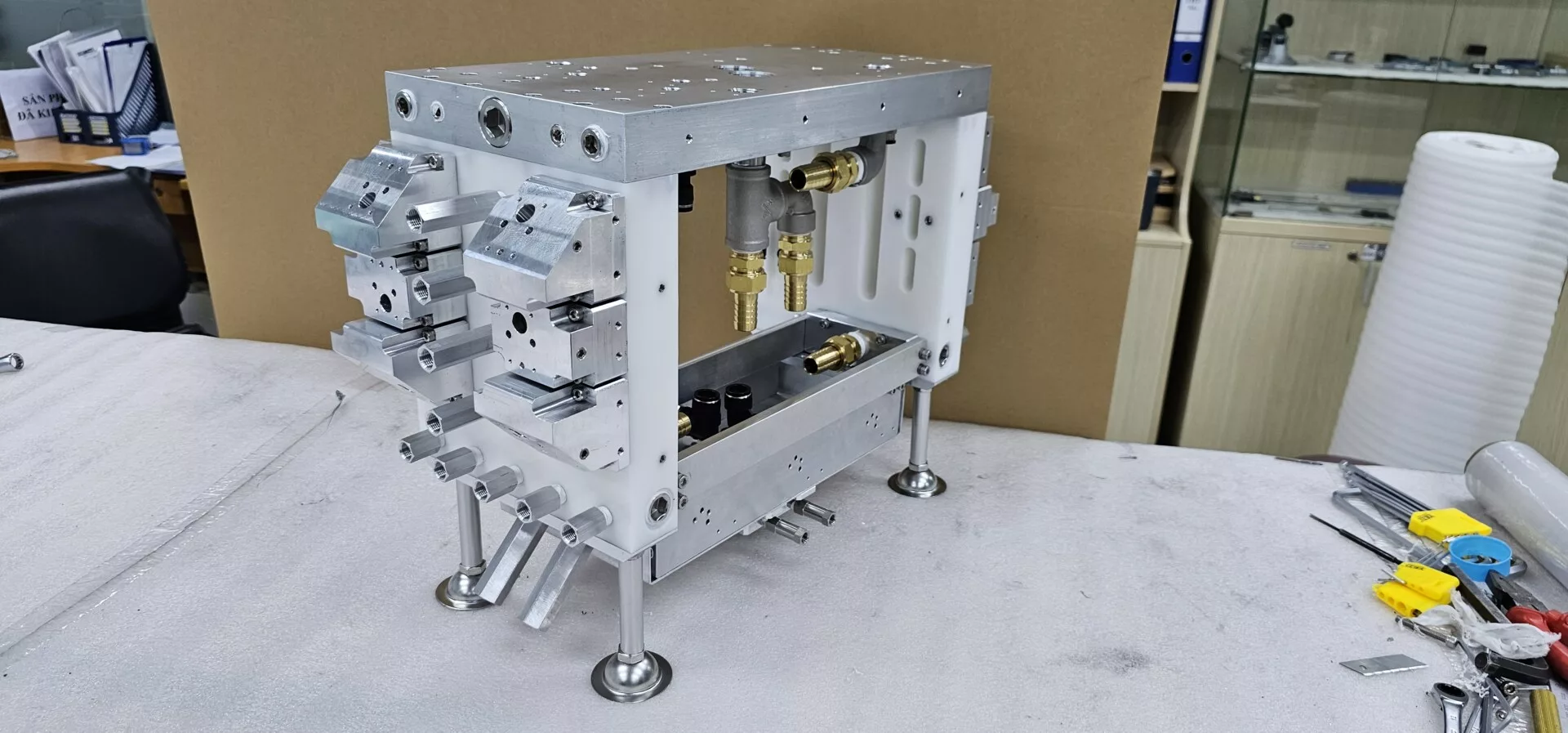

Modern machining centers, including CNC systems, often require customized jigs and fixtures tailored to unique geometries and part requirements. This calls for advanced machine design and drafting services that can deliver tailored solutions for complex applications.

By leveraging 3D CAD modeling, stress analysis, and simulation software, experienced design teams can create robust fixture systems that improve part access, support high-speed machining, and reduce vibration — all vital elements in precision operations.

Industries That Benefit from Precision Workholding Design

Various sectors depend on precision machining, and by extension, accurate jigs and fixtures. These include:

- Automotive: Ensuring reliable mass production of critical engine components

- Aerospace: Manufacturing structural components with tight tolerances

- Medical Devices: Producing complex surgical tools and implants

- Electronics: Assembling delicate, compact components with accuracy

Professionally crafted workholding designs support lean manufacturing principles, enabling these industries to meet stringent quality and productivity standards.

Partnering with the Right Jigs and Fixtures Provider

Choosing a reliable partner with proven expertise in jigs and fixtures design is key to maximizing your machining capabilities. Che tao may IDEA offers complete design-to-delivery support, including fixture conception, prototyping, and commissioning. Their team of engineers works closely with clients to ensure seamless integration into existing production flows.

For manufacturers looking to optimize complex machining tasks, IDEA provides innovative solutions using the latest technologies. You can explore more industrial-grade solutions through outlets like IDEA Techmart, which specializes in automation and high-tech engineering tools.

Enhance Your Machining with IDEA’s Expertise

At IDEA, we understand how critical jigs and fixtures are in high-precision environments. Our engineering team combines deep industry knowledge with cutting-edge design applications to deliver high-quality workholding designs that elevate your machining performance.

Whether you require solutions for high-volume production or custom low-batch manufacturing, IDEA is your trusted partner in precision machining excellence. Contact us today to unlock your plant’s potential through expertly crafted jigs and fixtures.