Precision Engineering – OEM Mechanical Assembly Units for Automated Production Lines

Precision Engineering – OEM Mechanical Assembly Units for Automated Production Lines

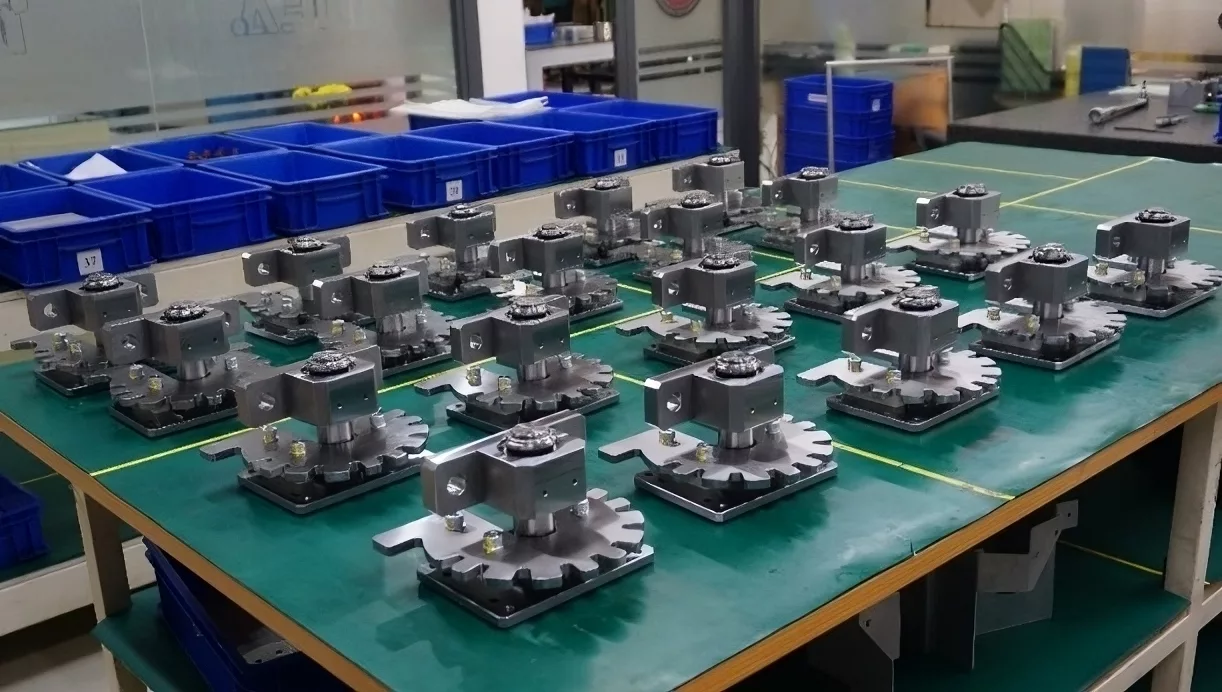

Full-cycle production, assembly, and quality inspection of 30 OEM mechanical assembly units featuring concentric ring gears and pre-installed bearings, designed for rotary clamping or drive systems in automation equipment

“IDEA delivered the order on time, with high precision, consistent assembly quality, and professional export packaging. An excellent fit for high-stability international orders.”

This project involved the production and assembly of 30 mechanical assembly units for an international client specializing in automation support equipment. Each unit included CNC-machined aluminum and steel components, pre-installed bearings, and a concentric ring gear serving as a drive or positioning element in mechanical systems.

The project required tight tolerance control, synchronized component integration, and consistent performance across all units to ensure compatibility with the client’s production line.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.