Industrial Equipment – Automated Assembly Line Systems

Industrial Equipment – Automated Assembly Line Systems

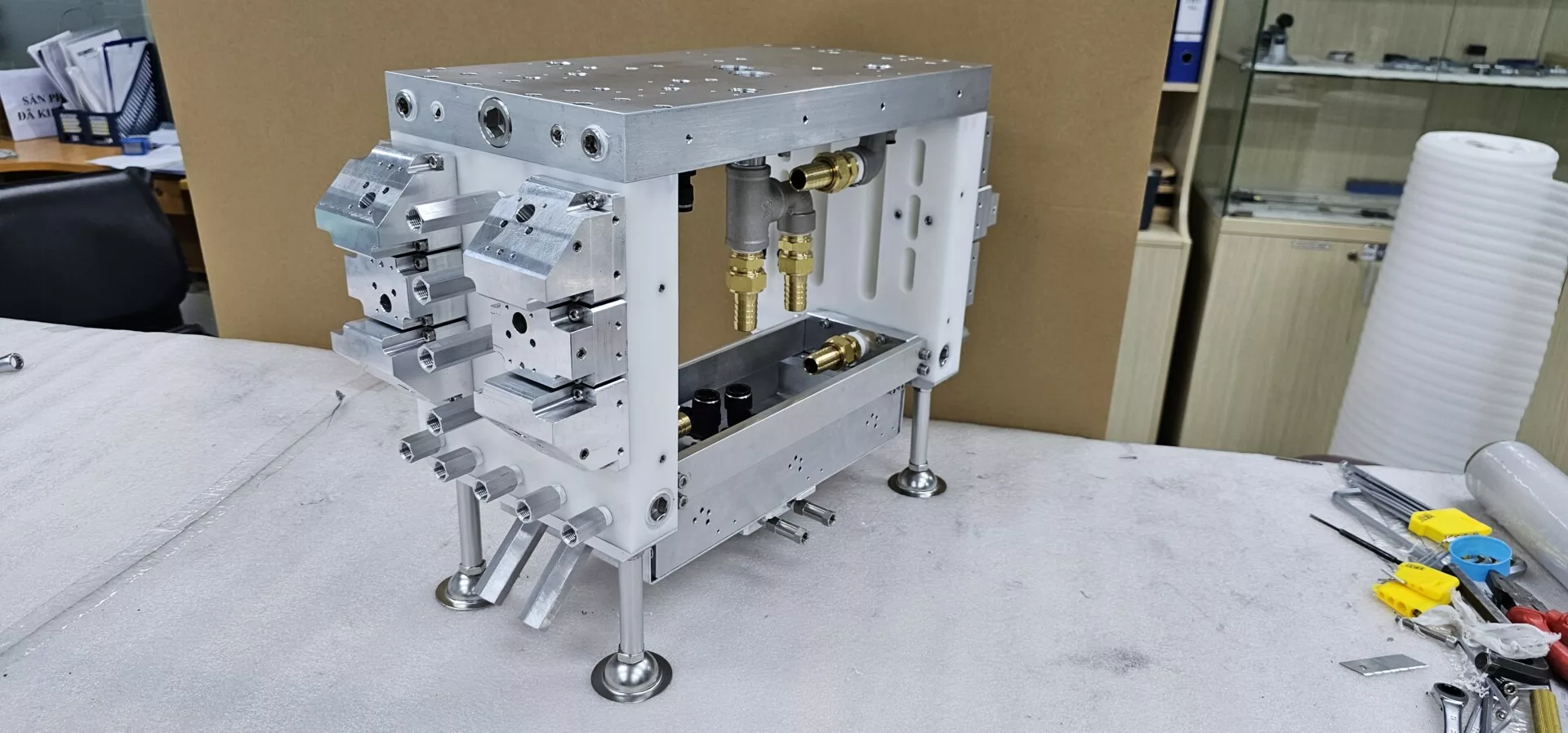

Precision machining and assembly of 10 OEM systems with integrated pneumatic components, based on engineering designs provided by a U.S. client.

“We are very satisfied with the mechanical quality and responsiveness from IDEA. The equipment was solidly assembled, aesthetically finished, and fully compatible with integration into our production line.”

This project involved OEM machining and assembly for a U.S.-based company specializing in automation equipment for electronics and electrical manufacturing. The client required 10 complete OEM systems to be produced in Asia based on detailed engineering drawings. These systems had to meet high standards of dimensional accuracy, structural stability, and seamless integration into existing automation lines.

IDEA was selected as the end-to-end supplier thanks to our rapid response capabilities and proven experience working with international clients.

The project was completed within 4 weeks, following a clearly defined process:

Collaborated directly with the client’s U.S. engineering team to ensure full understanding of specifications and standards.

Used 5-axis Mazak CNC machines and turning centers to process aluminum frames, stainless steel parts, and POM plastic components.

Performed anodizing and directional brushing on aluminum surfaces for enhanced appearance and oxidation resistance.

Installed the pneumatic components and pressure-tested all connections through 1,000 cycles to ensure zero leakage.

Completed export-standard packaging and provided detailed QC reports with each shipment.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.