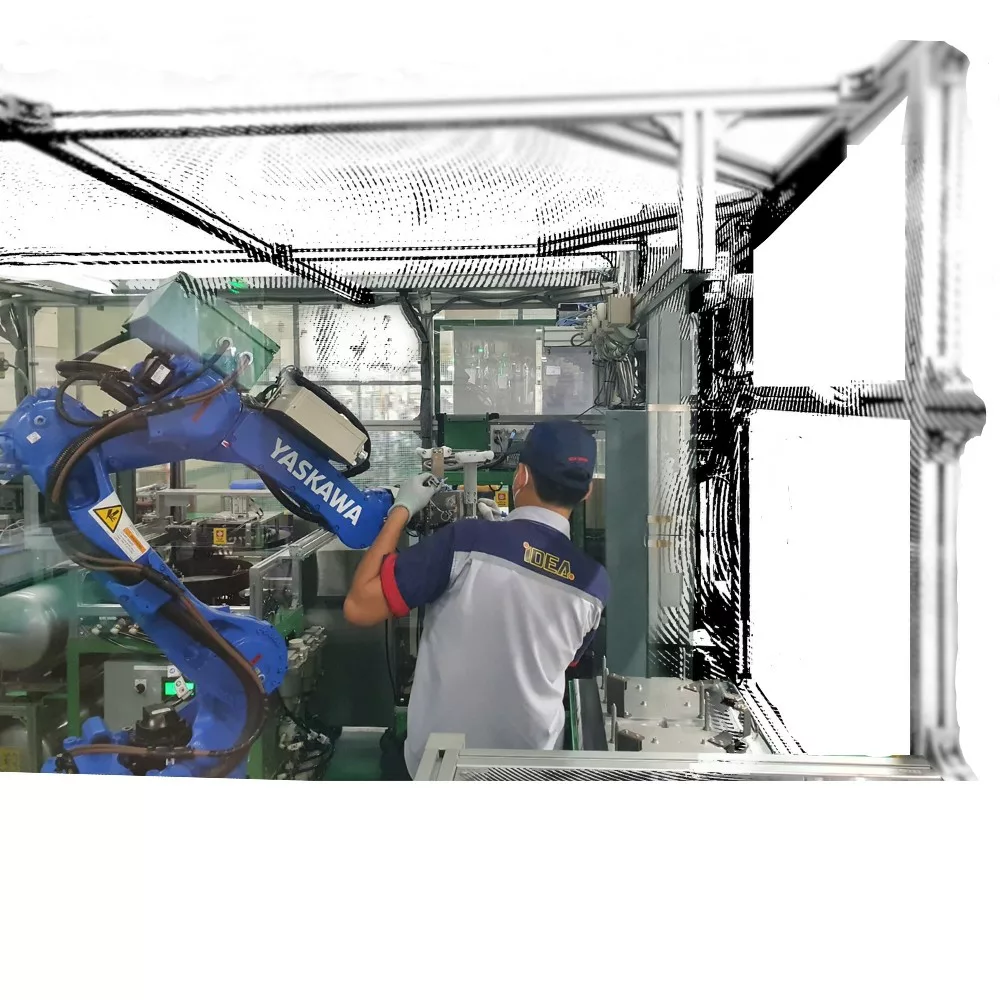

Transform Your Factory Operations with IDEA Group’s Engineering Excellence

At IDEA Group, we are committed to revolutionizing the way factories operate by providing comprehensive engineering solutions and services tailored to optimize production processes and maximize efficiency. Our mission is to empower businesses to transition toward smart manufacturing by integrating cutting-edge technology and creating streamlined, digitalized environments. We envision a future where factory managers and engineers are no longer bound by physical constraints, enabling seamless oversight and control from anywhere in the world.

What We Offer:

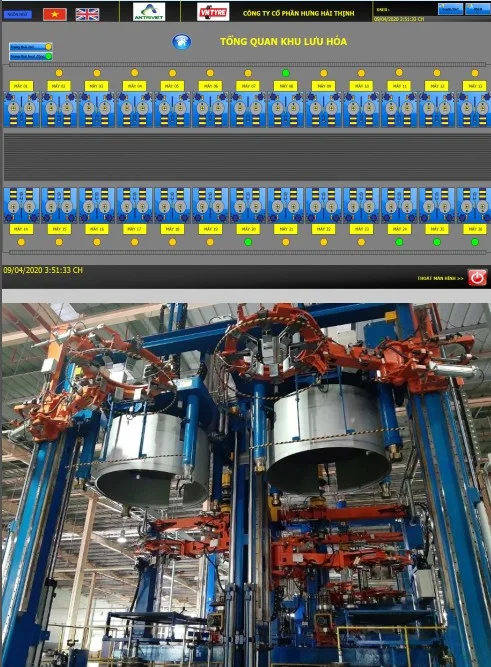

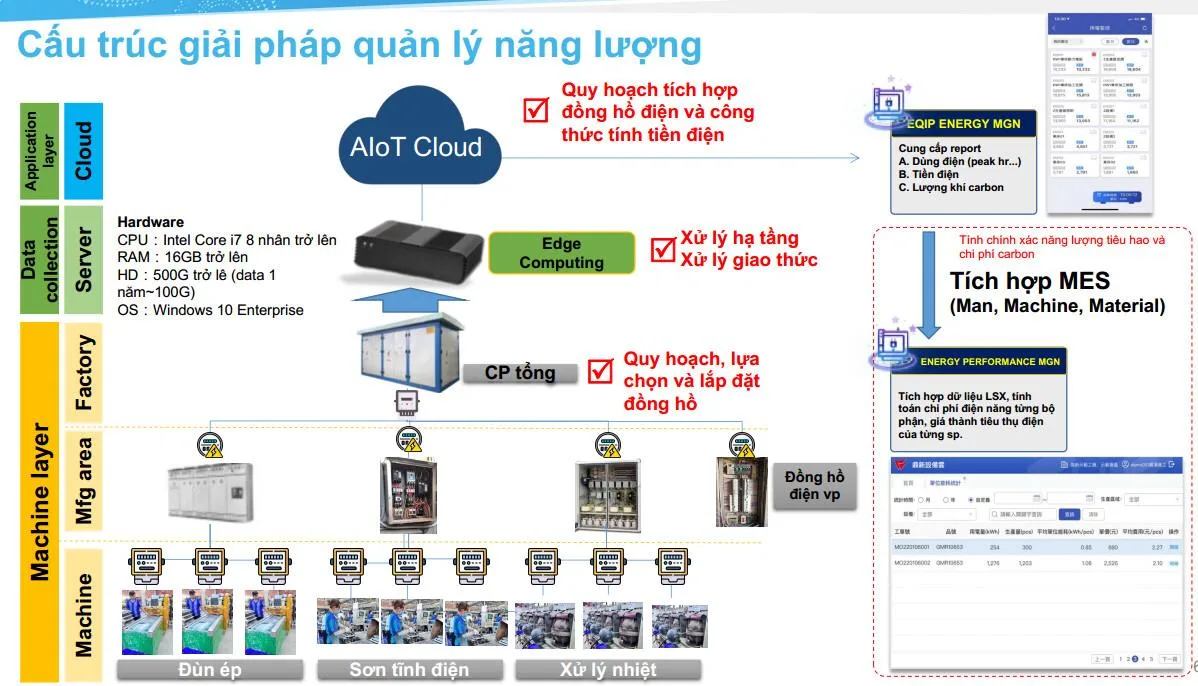

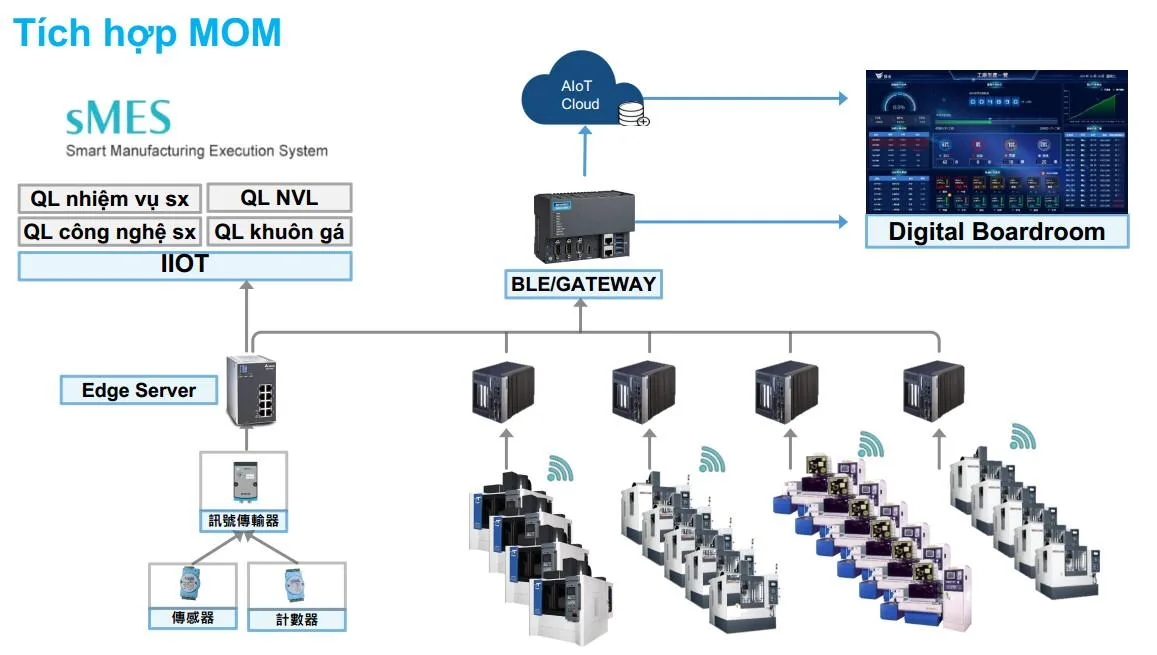

- Automation IoT & Smart Manufacturing Solutions: Harness the power of the Internet of Things (IoT) and automation to transform your production lines into highly efficient, interconnected systems that adapt to the ever-changing demands of modern industries.

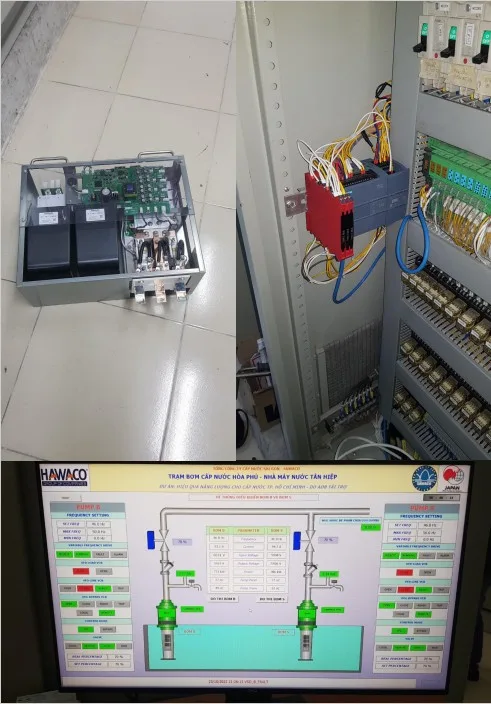

- Maintenance & Emergency Troubleshooting: Ensure uninterrupted operations with our fast, reliable troubleshooting services and proactive maintenance strategies to minimize downtime and prevent unexpected disruptions.

- Refurbishment & Upgrade of Old Machines: Extend the lifespan of your existing equipment with our expert refurbishment services and modern upgrades that boost performance and comply with the latest industry standards.

- Machinery Installation & Startup: From initial setup to operational readiness, we handle every step of machinery installation, ensuring seamless integration into your production line.

- Long-term Maintenance & Equipment Record Refresh: Maintain peak performance with our long-term maintenance plans, complete with updated records and detailed tracking for all your machinery.