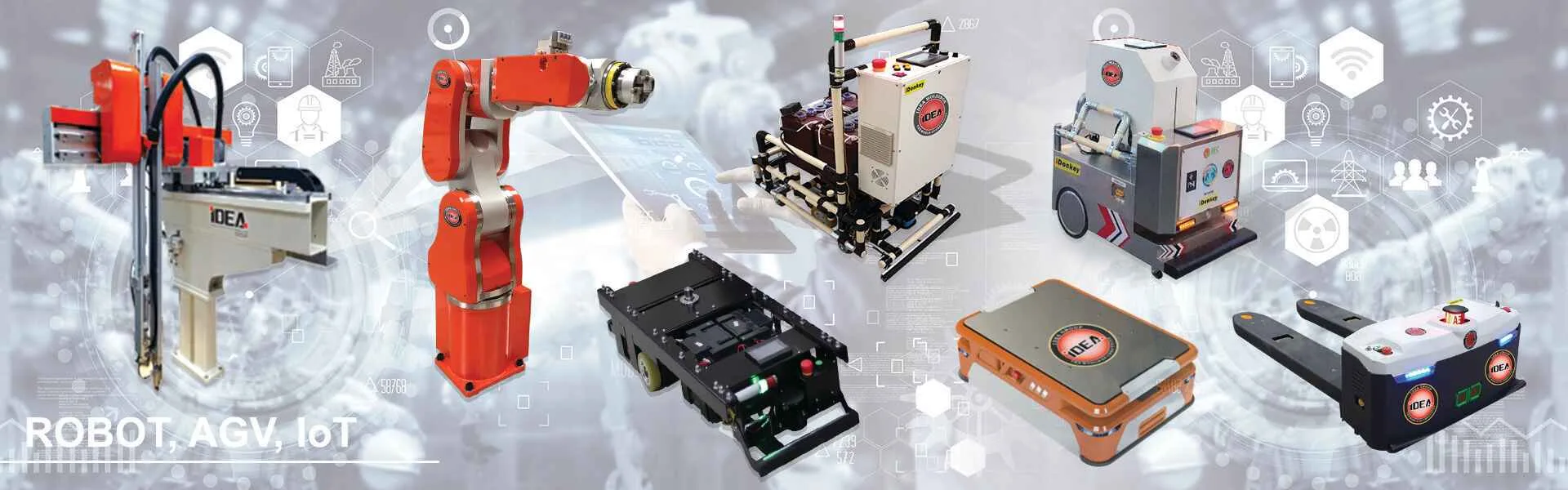

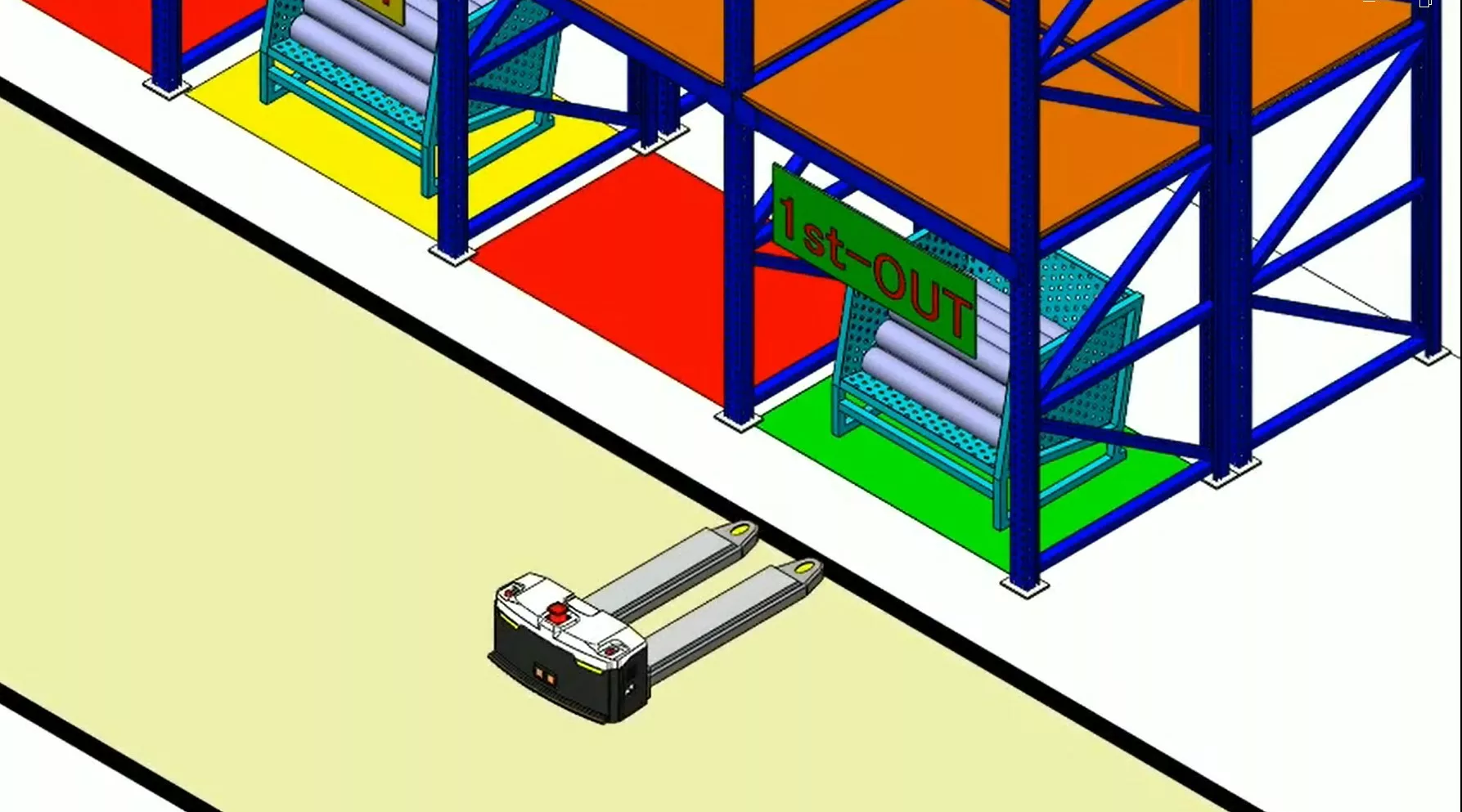

Automated Guided Vehicles (AGVs) are advanced and versatile transportation automation solutions, widely used in many industries to improve the efficiency of material and goods handling. With the ability to move pallets, racks, carts, and containers in factories and warehouses, AGVs not only help to increase productivity but also optimize production processes, support highly repetitive tasks.

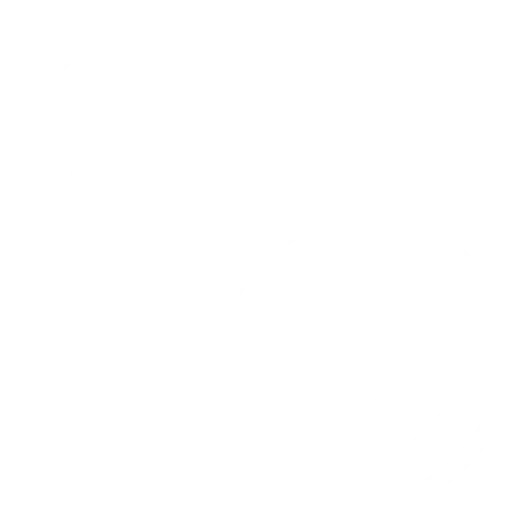

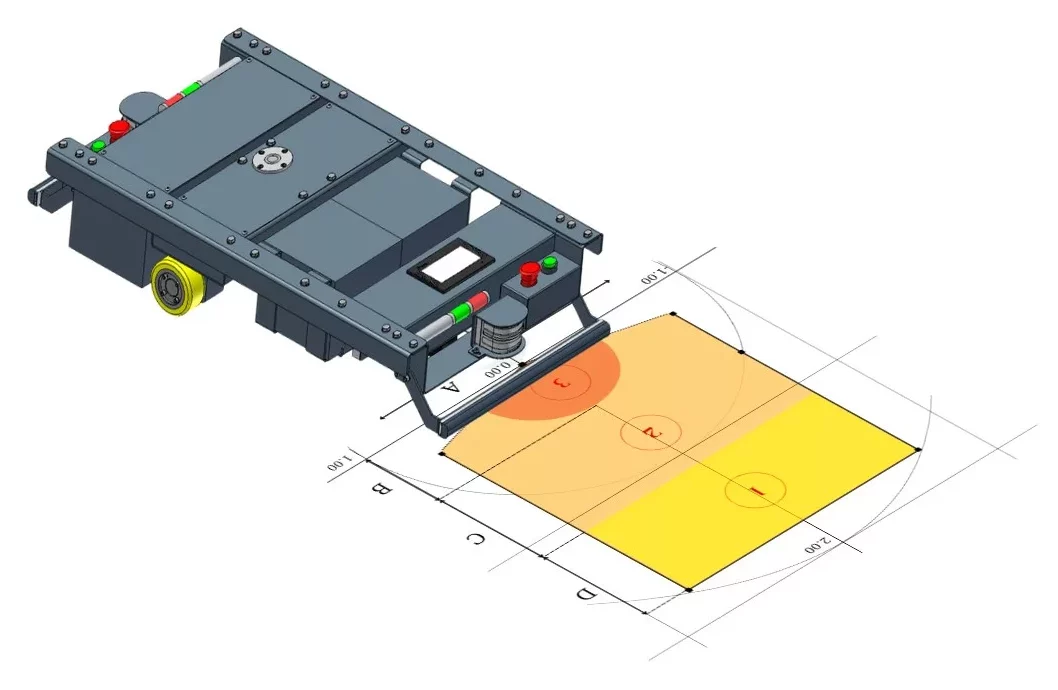

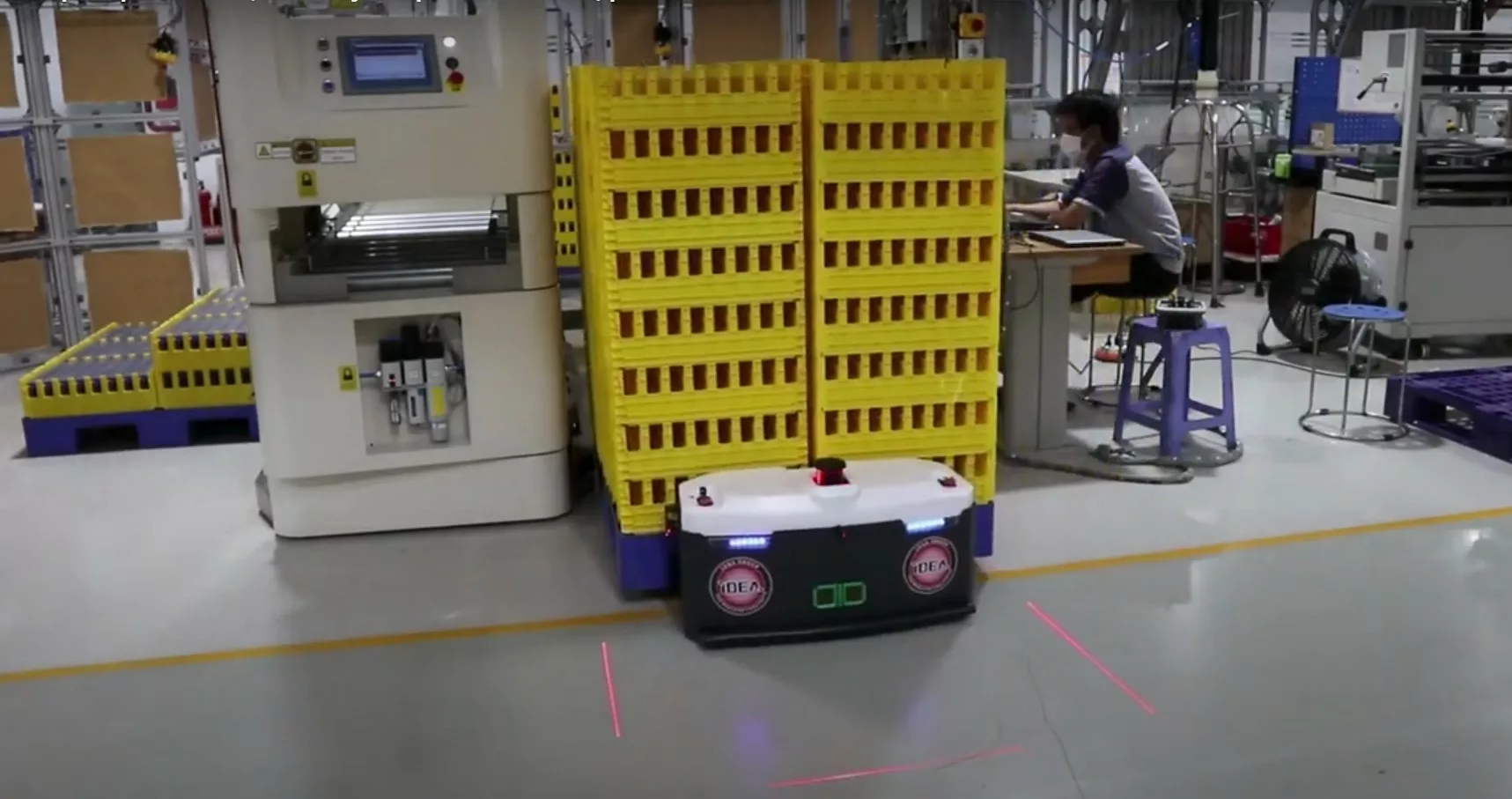

iDonkey, IDEA’s AGV brand, provides automated transportation solutions in factories and warehouses. Equipped with advanced technology and modern control systems, Idonkey helps to optimize production processes, improve safety and operational efficiency. iDonkey autonomous robots are diverse in models with two main guidance methods: magnetic lines and SLAM. In addition, iDonkey also has flexible cargo carrying capabilities with pulling, carrying and lifting functions, meeting many different transportation needs.