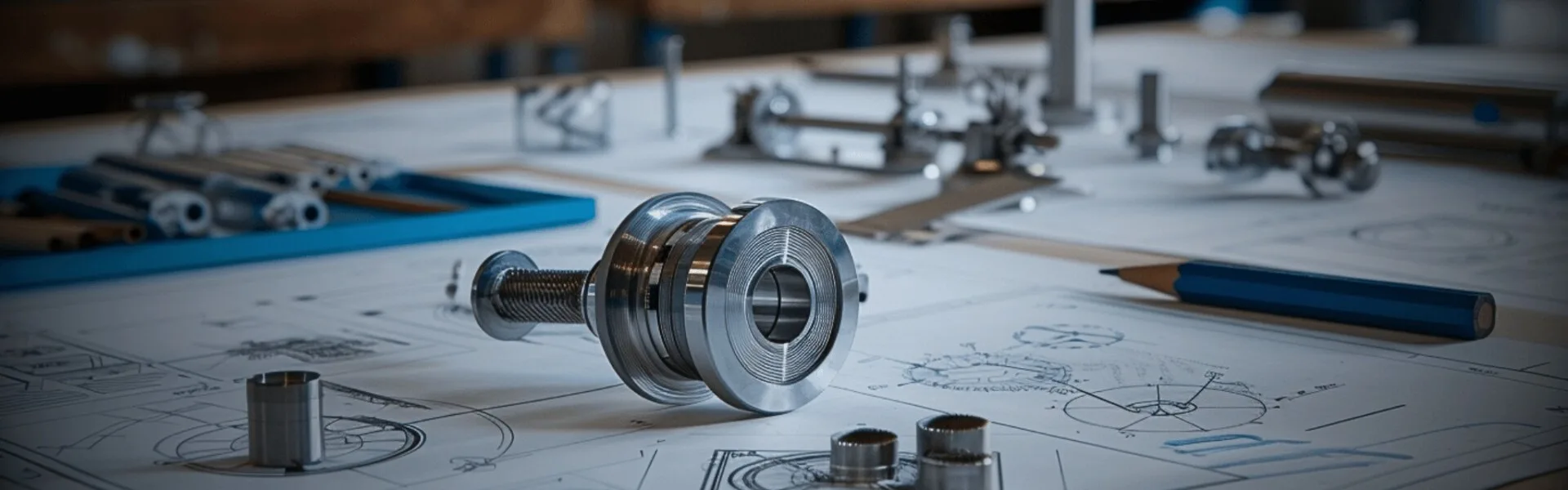

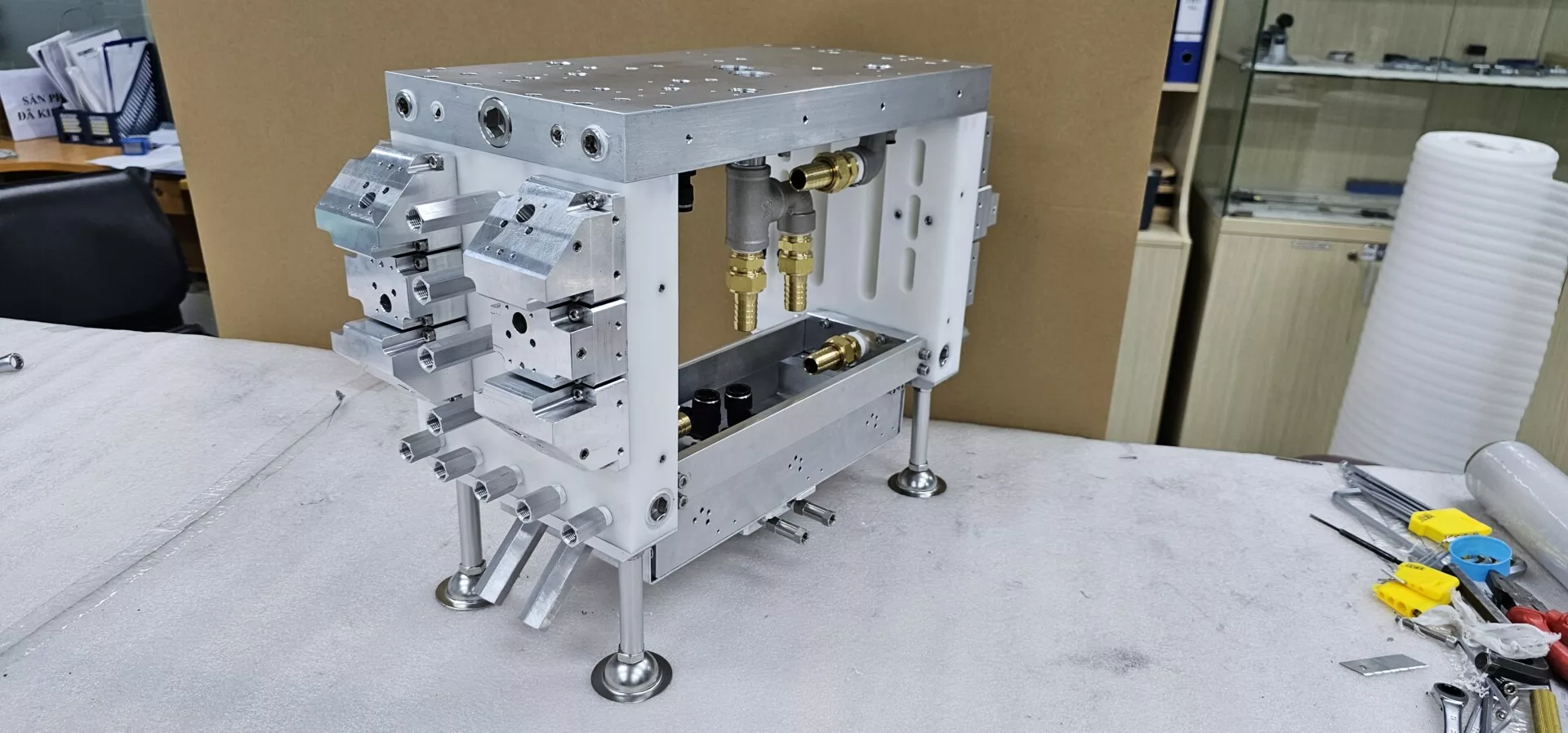

IDEA is one of Vietnam’s top-tier design and drafting specialists and a renowned manufacturer of automated machinery, with extensive experience and a proven track record in the field of precision mechanical processing. Our products primarily serve customers in Japan and the United States, earning a strong reputation for reliability and quality.

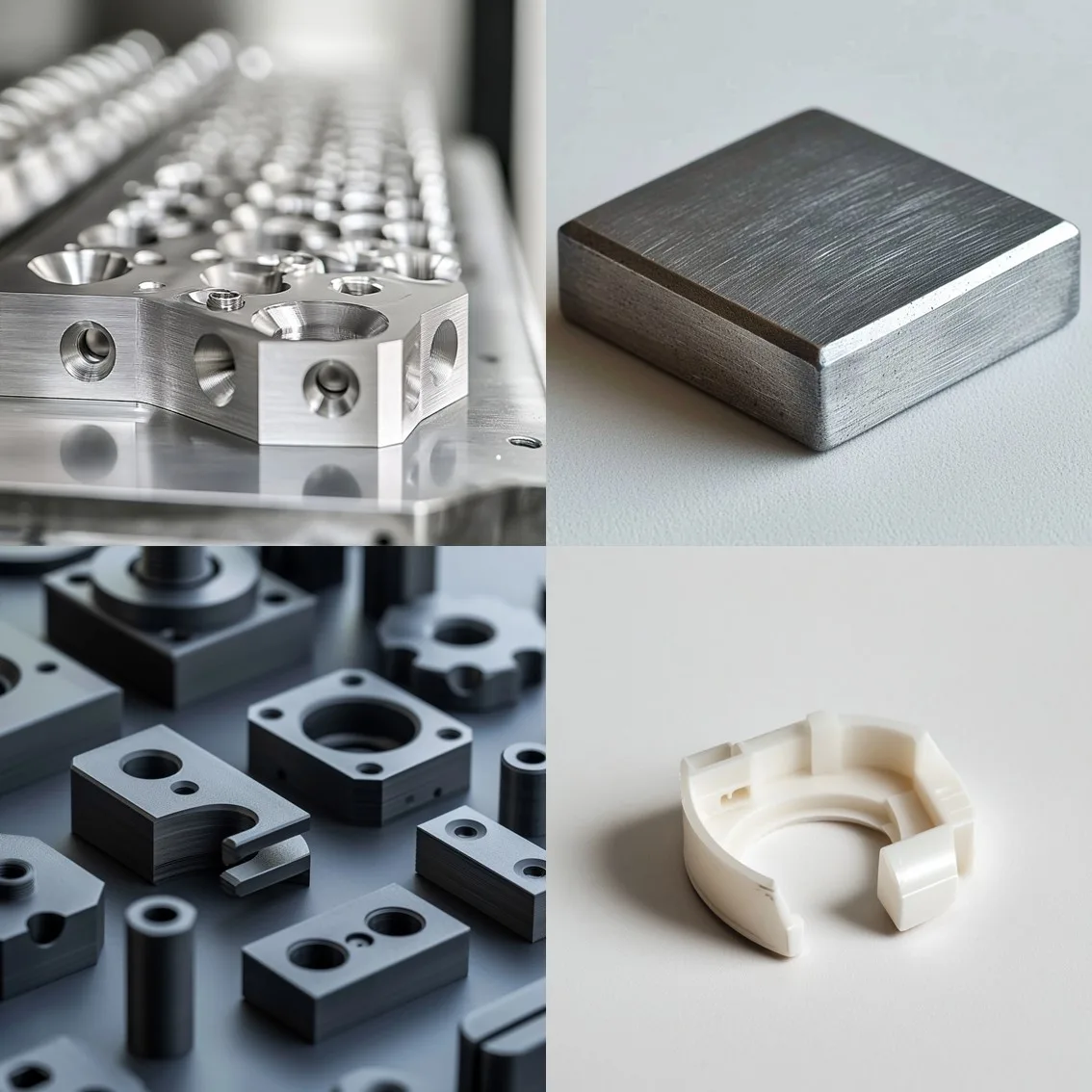

At IDEA, we go beyond providing precision processing services by offering professional consulting on processing methods, material selection, and tolerance settings.

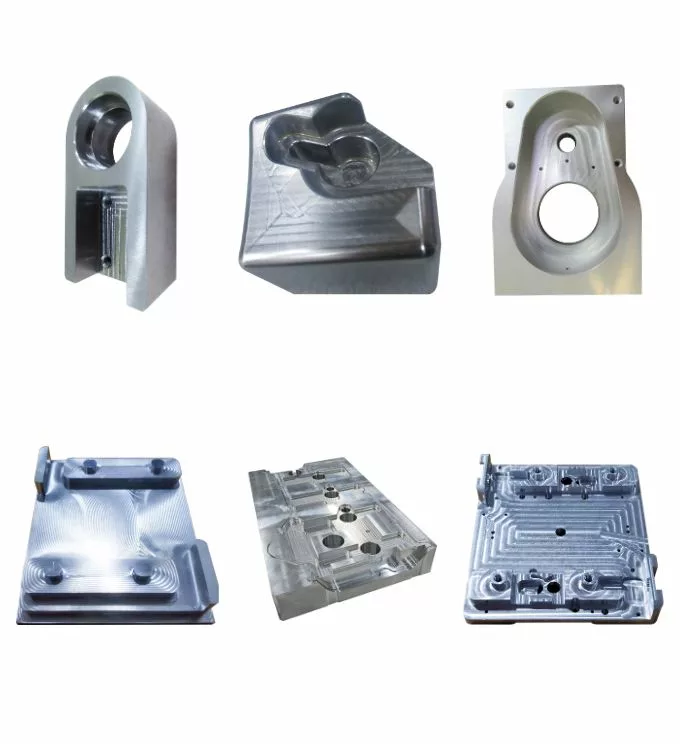

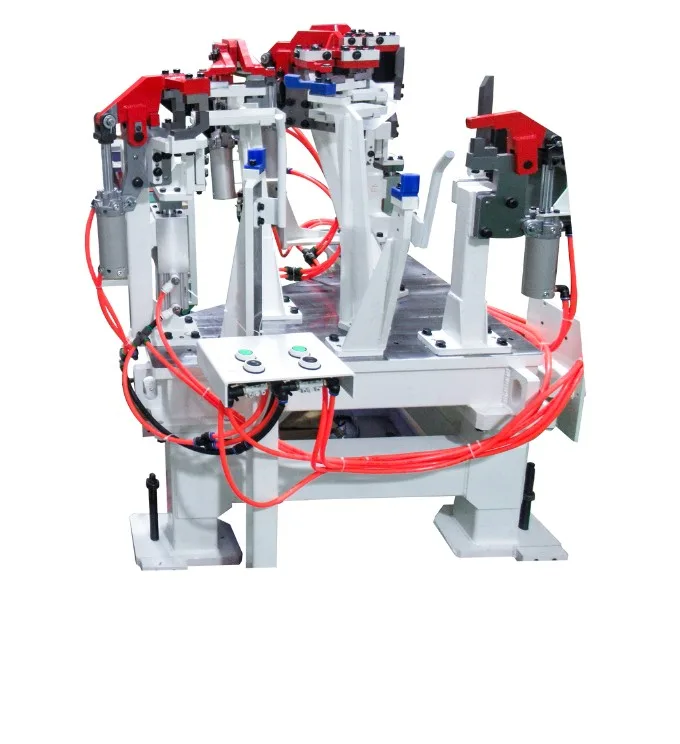

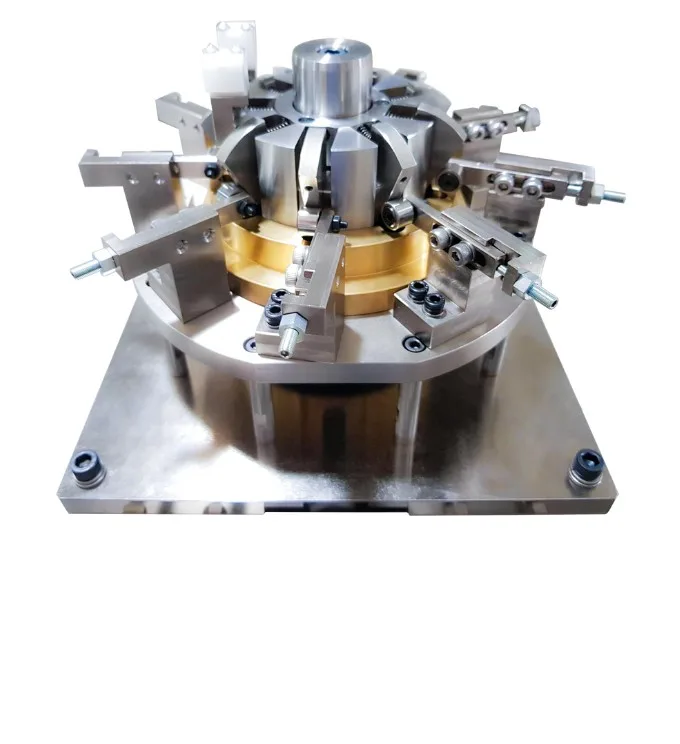

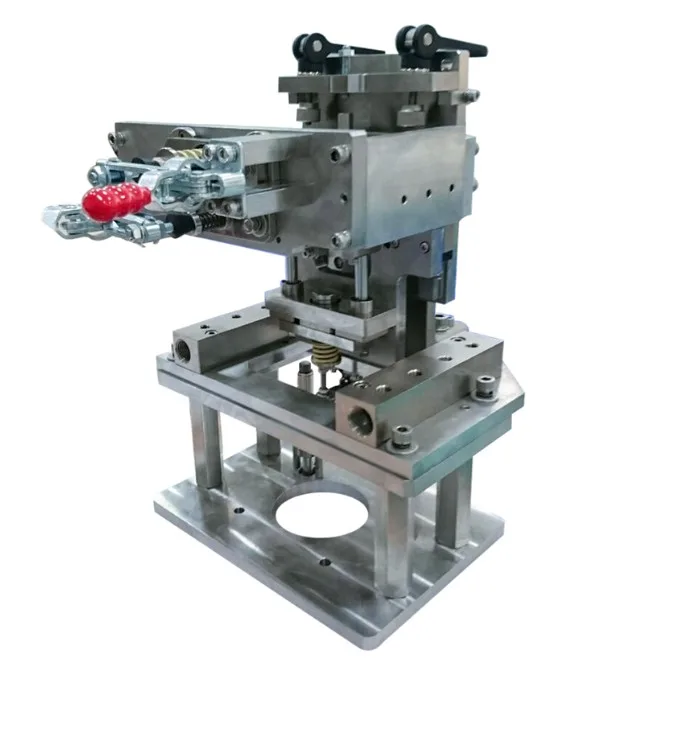

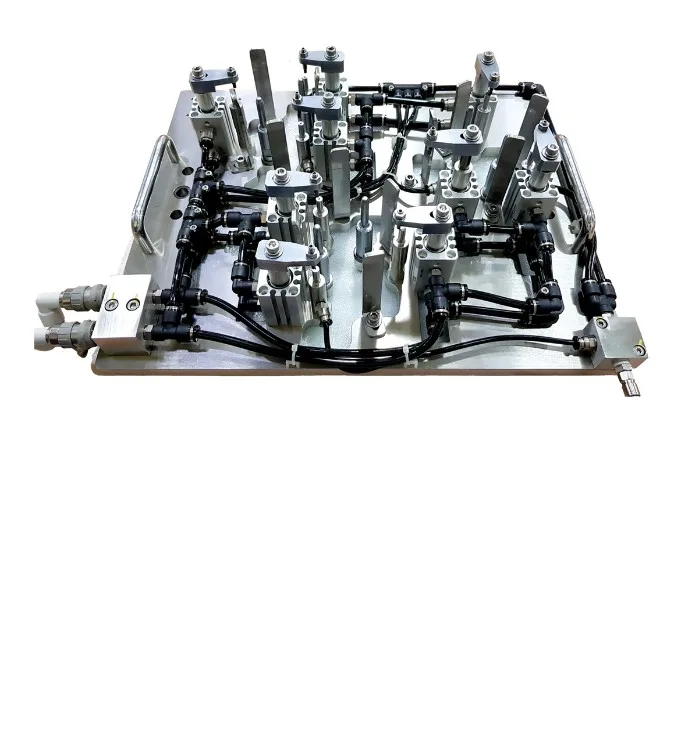

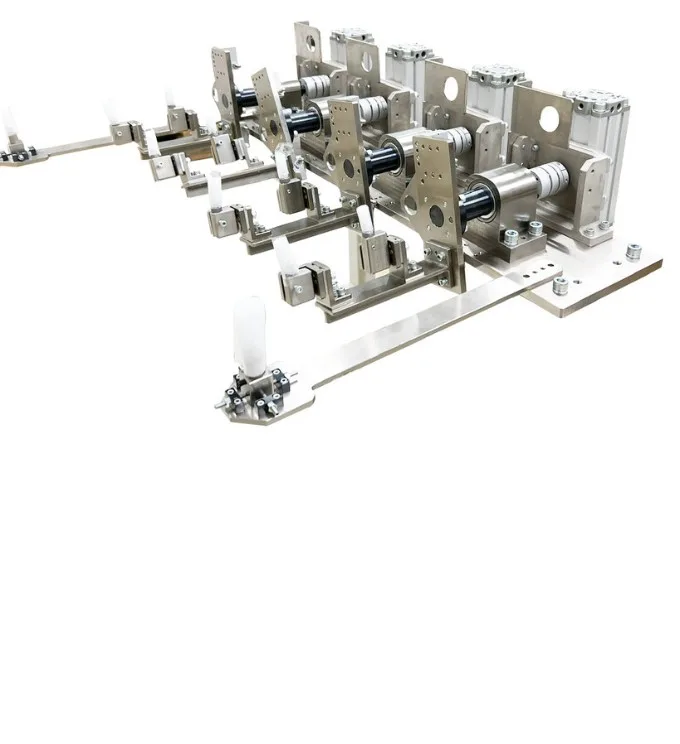

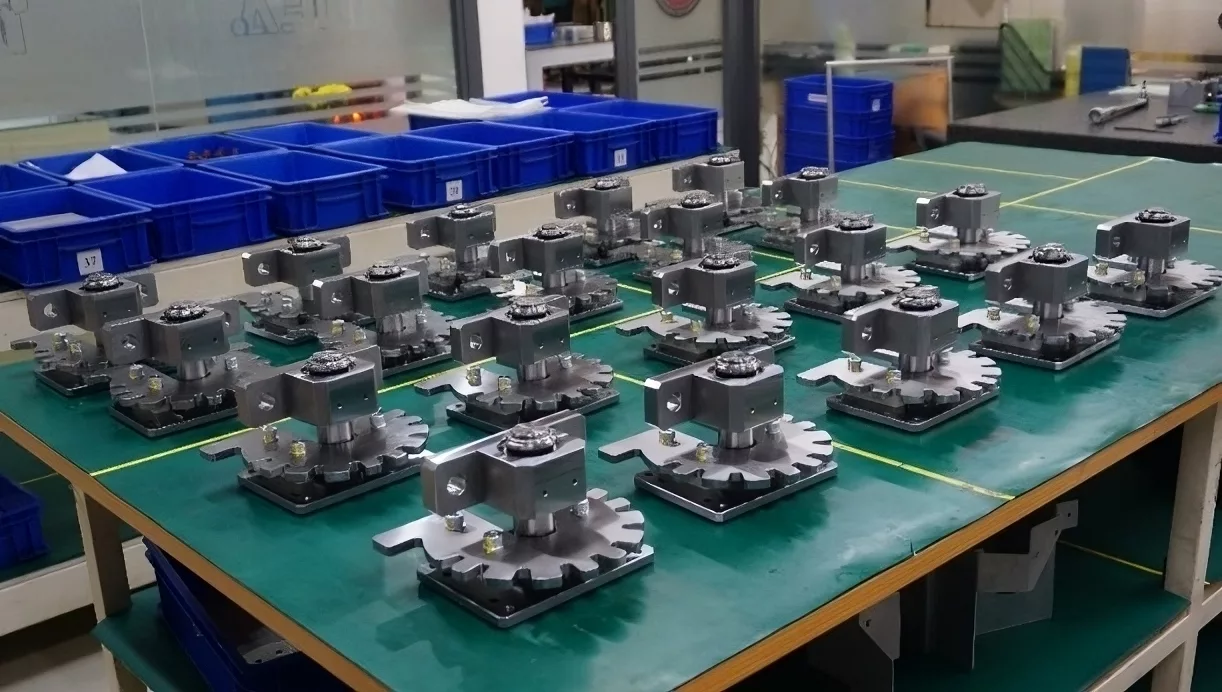

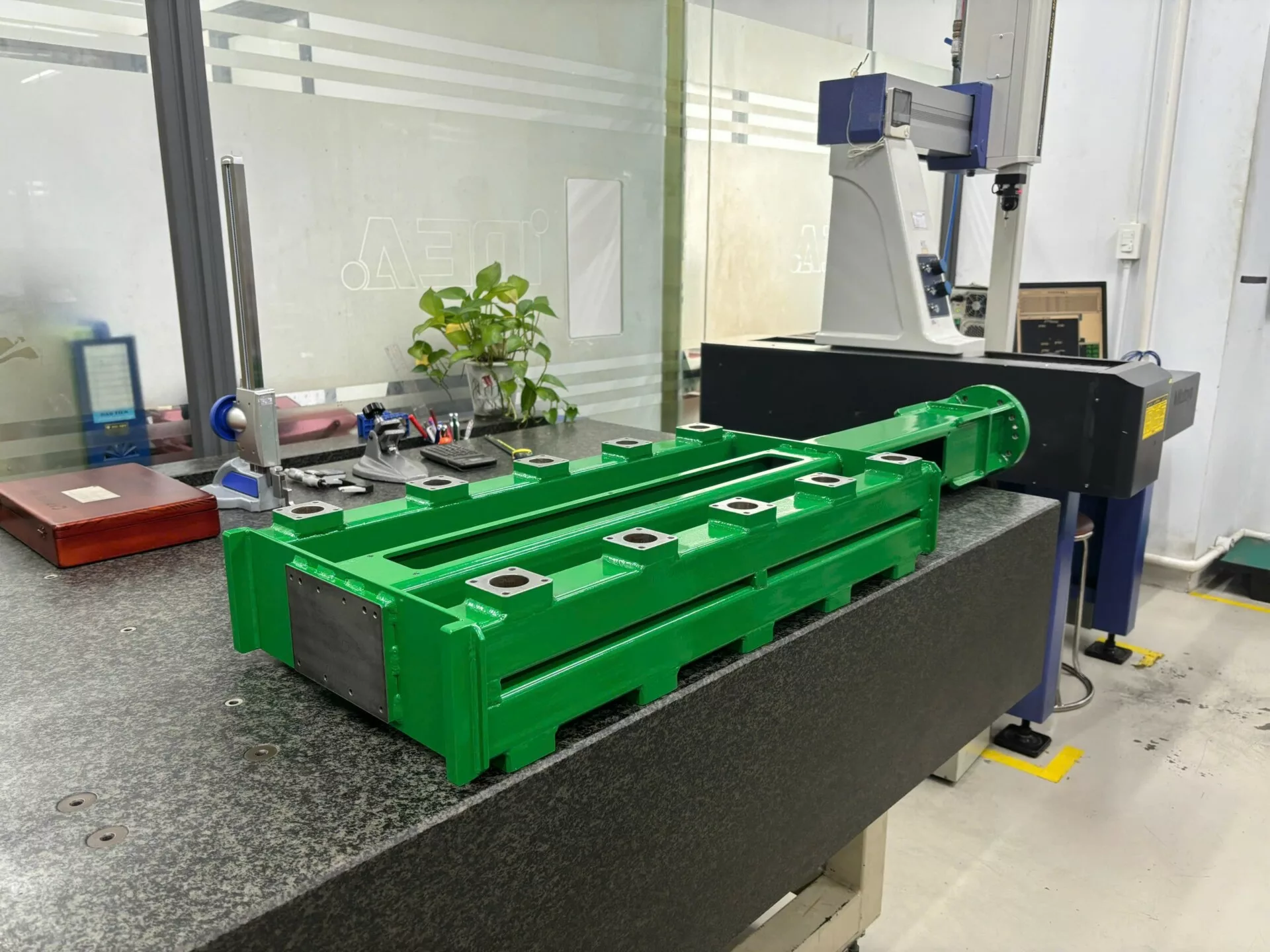

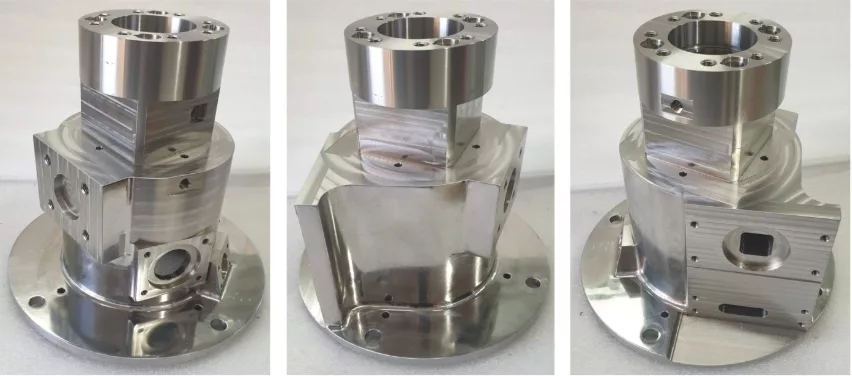

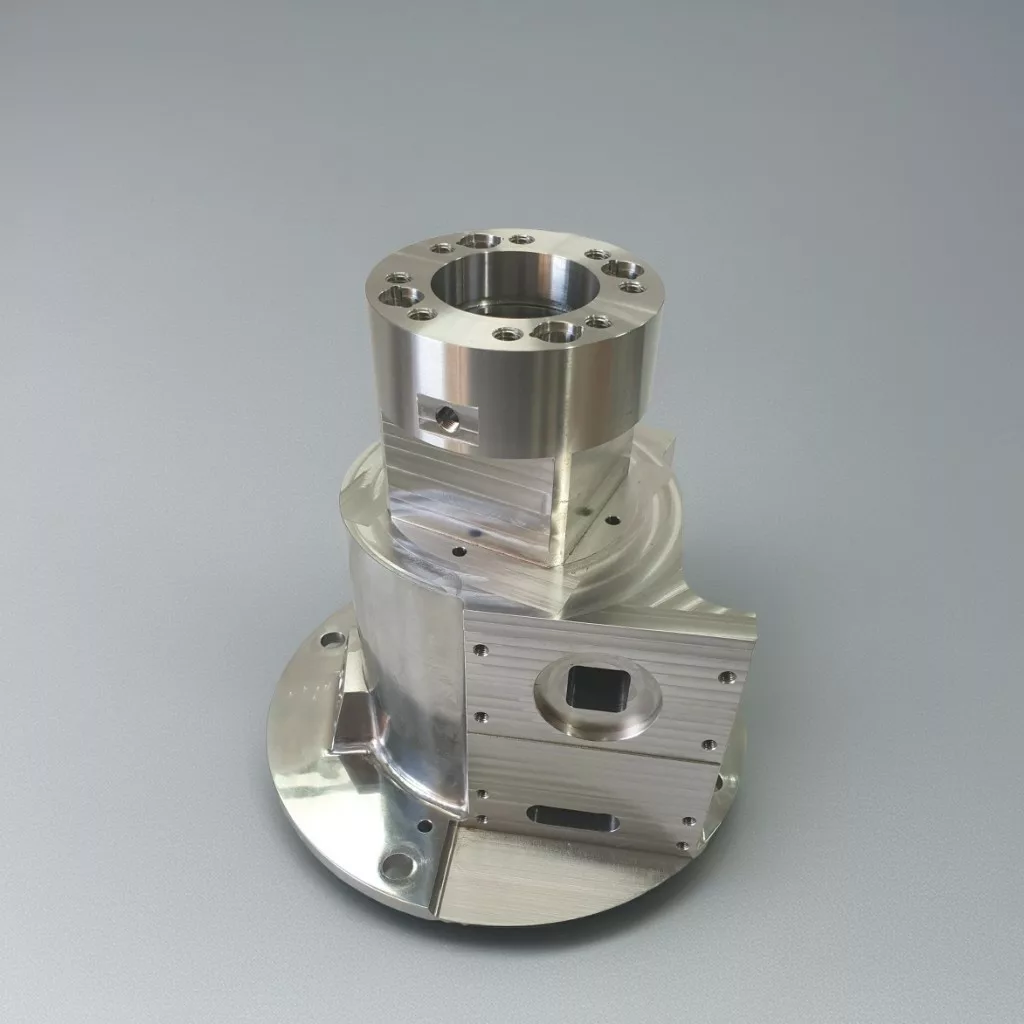

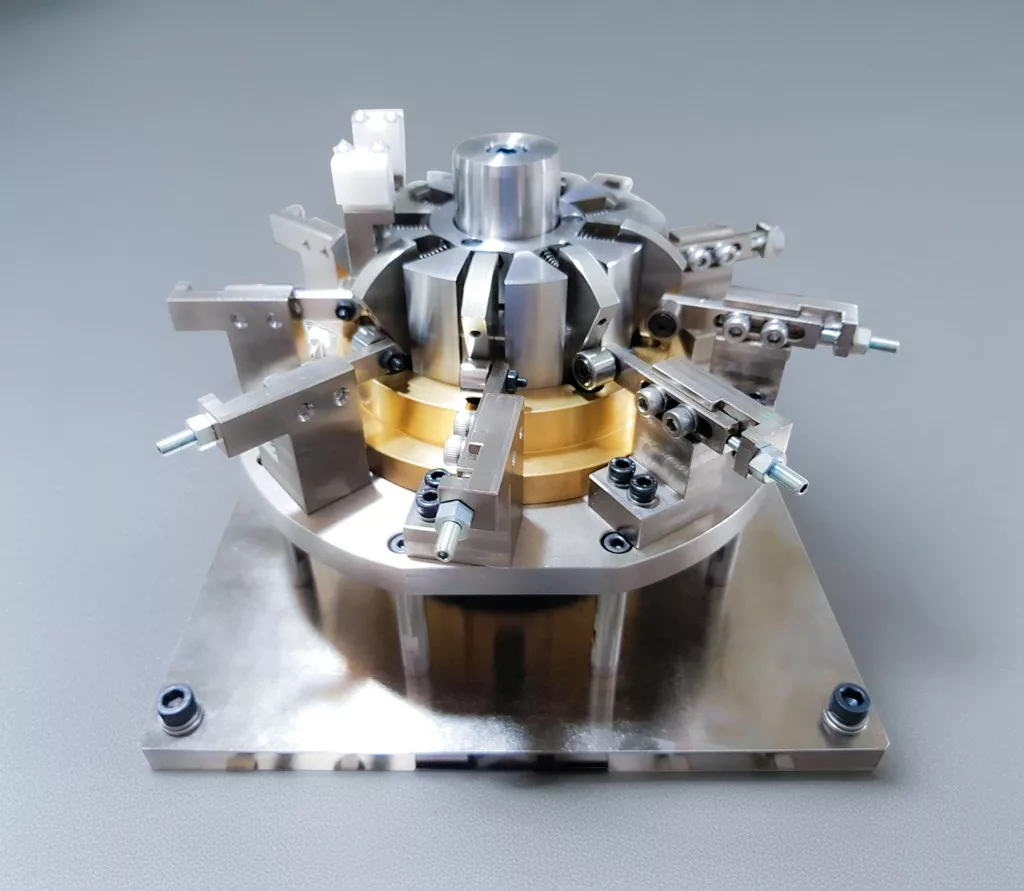

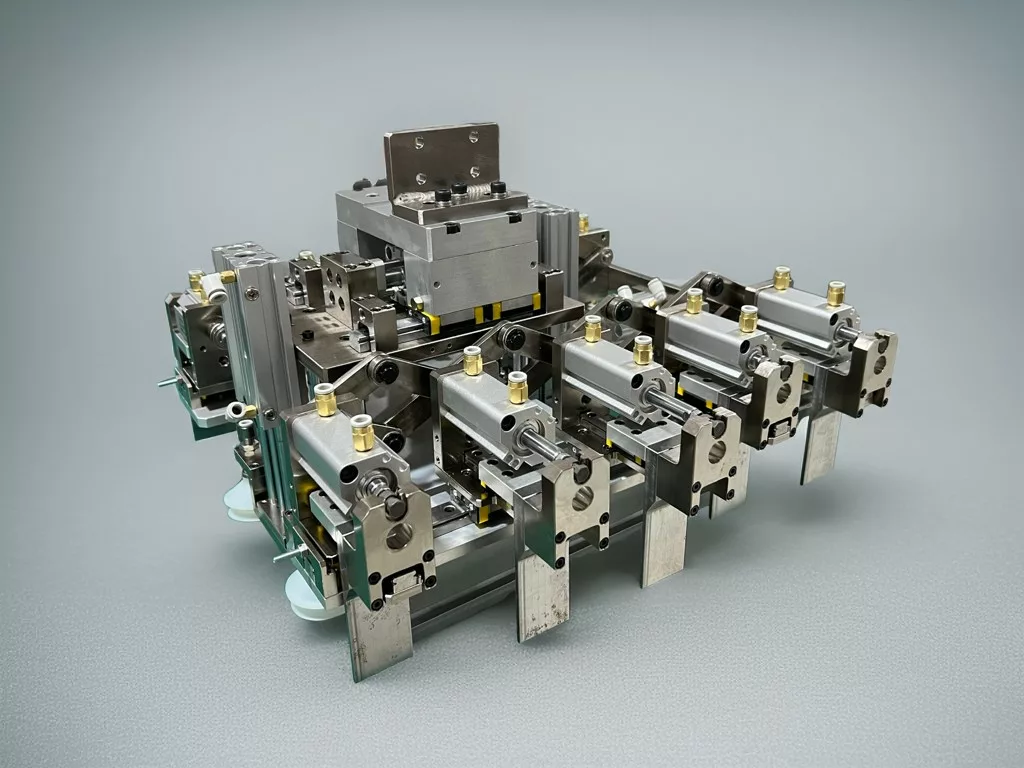

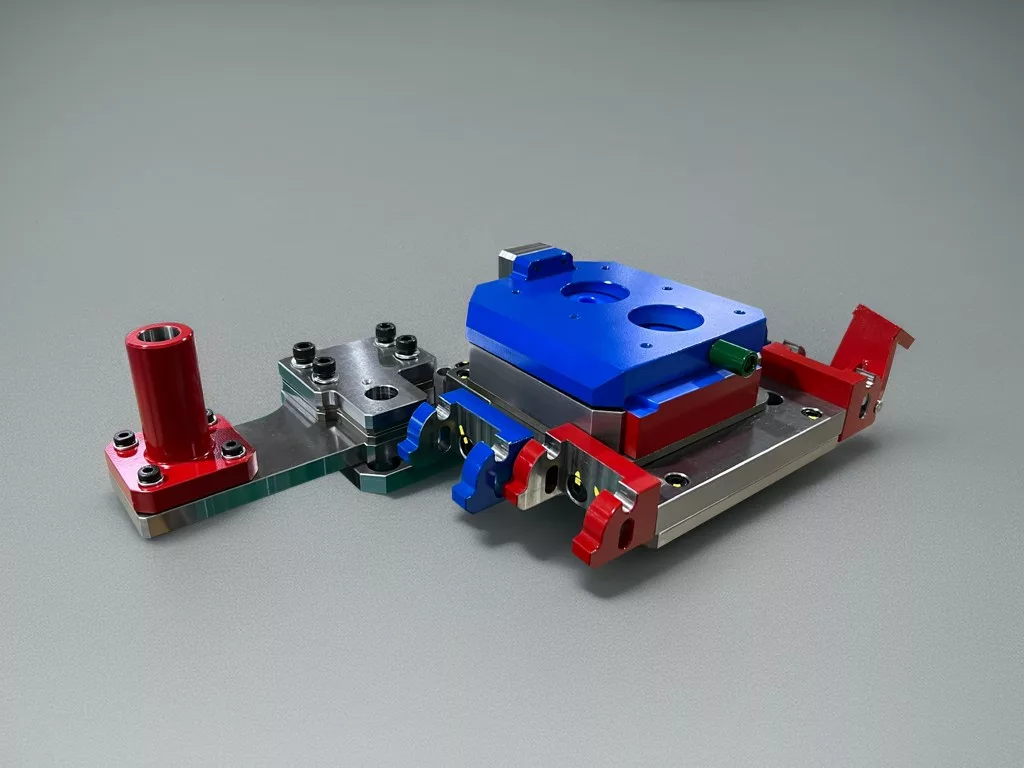

We specialize in machining mechanical components, welded and fabricated parts, and machine frames. Additionally, we excel in creating high-value jigs tailored to specific customer needs. By leveraging advanced technologies and state-of-the-art equipment, we deliver precision and efficiency in every project.