Design and manufacture of automatic packaging machinery systems for the food, pharmaceutical and consumer goods industries.

Design and manufacture of automatic packaging machinery systems for the food, pharmaceutical and consumer goods industries.

“The intuitive 3D model helps us reduce errors and optimize the manufacturing process.”

“IDEA responds quickly, supports flexible and efficient design editing.”

“IDEA’s machine design support solution helps us shorten design time by 20% and reduce production costs.”

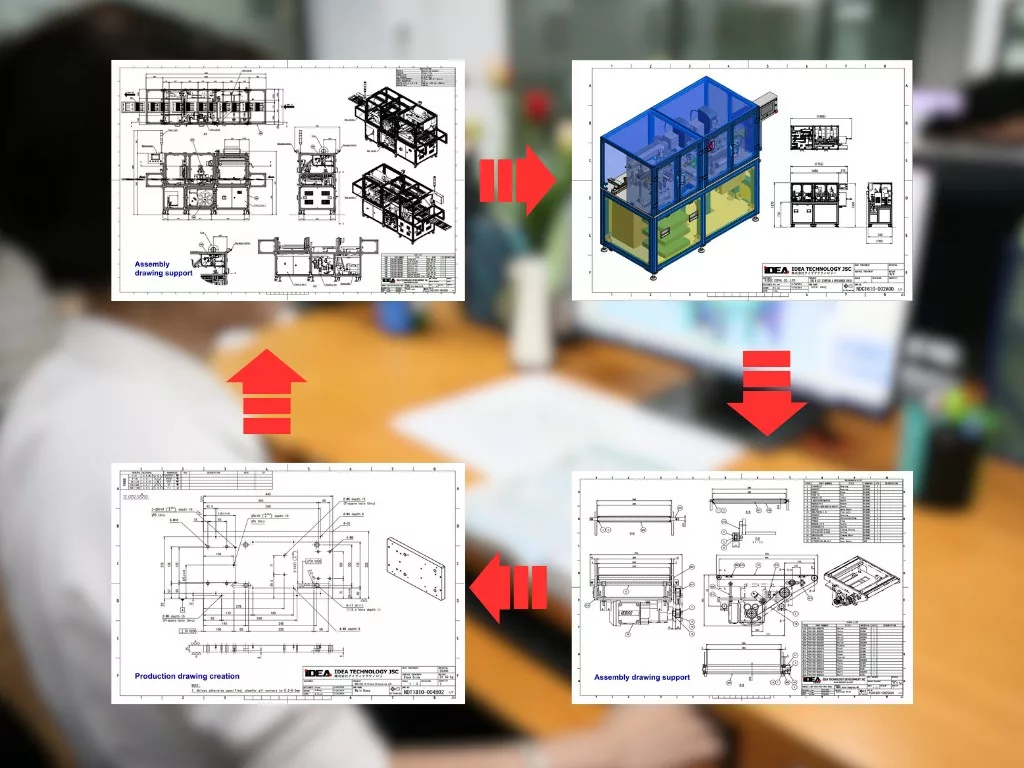

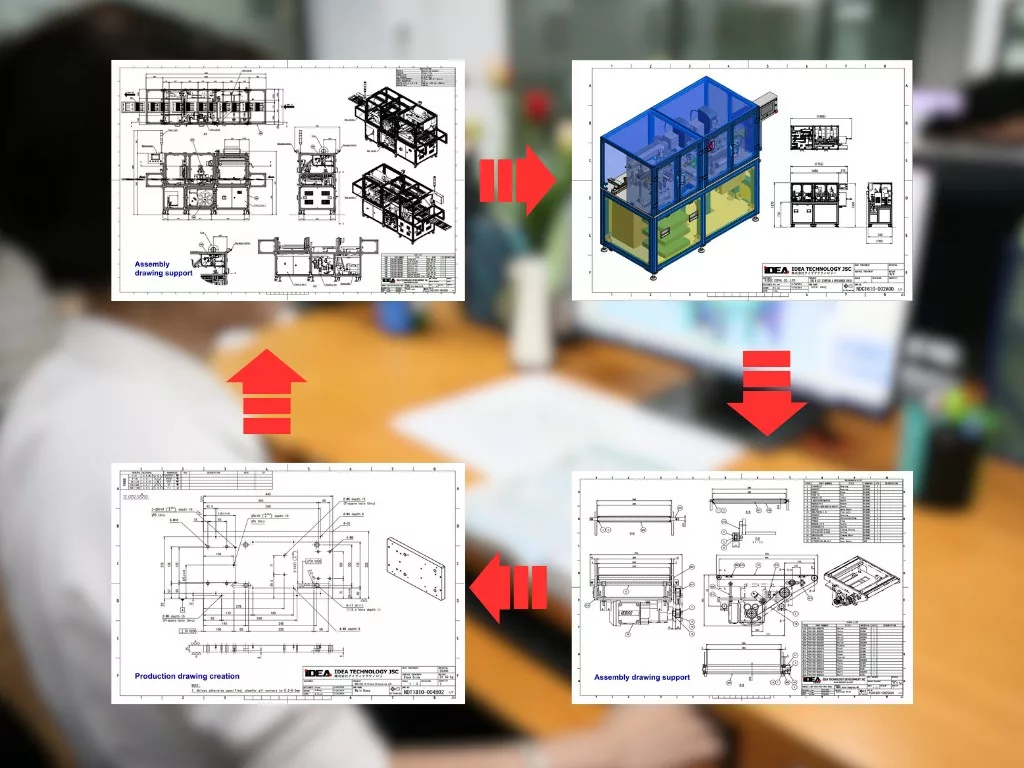

The client is a leading provider of product packaging solutions, specializing in the design and manufacture of automated packaging systems for the food, pharmaceutical, and consumer goods industries. To enhance efficiency in the design process, the company collaborated with IDEA to provide machine design support machine design by converting existing 2D drawings into 3D models, making customer-specific adjustments, and providing detailed fabrication drawings. Machine Design Support

Collaborating with IDEA helped the client efficiently transition from 2D to 3D designs, implement flexible changes, and provide high-quality fabrication drawings. With a professional workflow, an experienced engineering team, and the ability to respond flexibly to customer needs, IDEA became a trusted partner in optimizing the design process and better meeting customer requirements.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.