Consumer Goods Manufacturing –Thermal Insulation Product Manufacturing

Consumer Goods Manufacturing –Thermal Insulation Product Manufacturing

Automated Temperature Control Solution for 300°C in the thermal insulation product manufacturing process, helping to maintain product quality, check insulation performance, while minimizing human intervention and optimizing production efficiency.

IDEA Group’s automated temperature control solution has helped us ensure superior product quality for our thermal insulation products, with excellent insulation performance and no heat leakage. The current production process is stable, with a cycle time of only 6 seconds per product, which enhances efficiency and reduces production errors. This automation system not only saves us time and costs but also improves accuracy in quality control.

In the production of thermal insulation products, it is essential to ensure that the internal temperature reaches the specified level and is maintained within precise limits for the required duration. Any failure to meet these temperature standards or excessive fluctuations can adversely affect the product’s insulating properties, resulting in poor quality. Additionally, preventing heat from escaping the product is a critical aspect of the process.

The client requested an automated system to elevate the temperature of the products to 300°C within 15 minutes, followed by a performance test to evaluate insulation capabilities and detect any heat loss. To achieve these goals, the company required a solution that offered high accuracy, automation, and minimal human involvement during both the heating and testing stages.

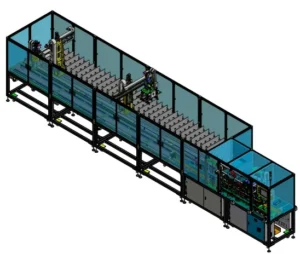

IDEA Group developed and implemented an automated heating system for the production of thermal insulation products. This system is programmed to maintain an internal temperature of 300°C for 15 minutes. After that, the system automatically checks for any heat leakage outside the product using advanced thermal sensors. Products are then classified as NG (Not Good) or OK (Good) based on the test results.

IDEA Group’s automated temperature control solution delivered remarkable results for the client, significantly improving both product quality and production efficiency. Key achievements include:

In summary, IDEA Group’s automated temperature regulation solution transformed the client’s production line, helping them maintain superior product quality, increase production efficiency, and reduce human intervention, while also improving their overall operational performance.

IDEA is one of the leading companies in Vietnam in the fields of design, precision machining, machinery manufacturing and automation solutions. With a team of over 195 talented and experienced engineers working according to high technical standards, IDEA provides innovative and efficient solutions that enhance performance and optimize costs for customers. The group is expanding its market share internationally, affirming its position as a trusted partner of major companies from Japan, the U.S., Canada, and many other countries.