3D printing technology has revolutionized the way machine prototyping is done in recent years. Rapid prototyping, enabled by 3D printing, has significantly accelerated the product development process in the industrial, manufacturing, automation, and technology sectors. This innovative approach allows for quicker iterations, cost-effective solutions, and greater design flexibility.

The Benefits of 3D Printing in Machine Prototyping

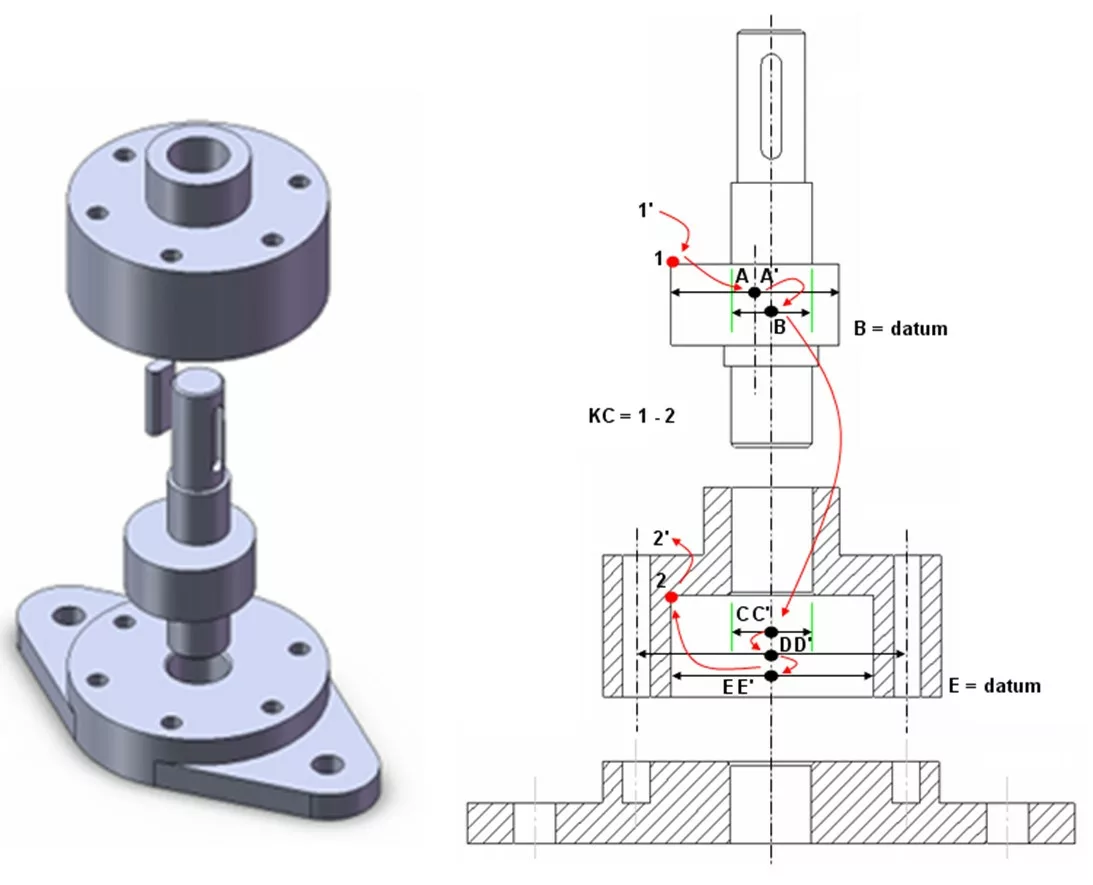

One of the key advantages of using 3D printing in machine prototyping is the ability to create complex geometries that are challenging or impossible to achieve with traditional manufacturing methods. This technology allows engineers and designers to rapidly test multiple design iterations, leading to faster product development cycles.

- Cost-Effective Prototyping

- Design Flexibility

- Reduced Time-to-Market

3D Printing Materials

3D printing offers a wide range of materials to choose from, including plastics, metals, ceramics, and composites, allowing for diverse applications in machine prototyping. Each material has unique properties that cater to specific design requirements, providing engineers with the flexibility to select the most suitable material for their prototypes.

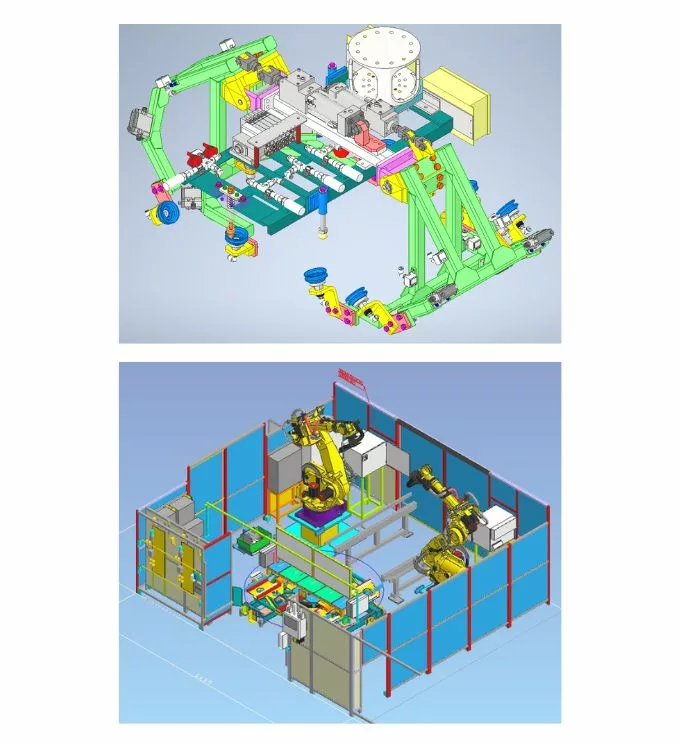

Applications of 3D Printing in Machine Prototyping

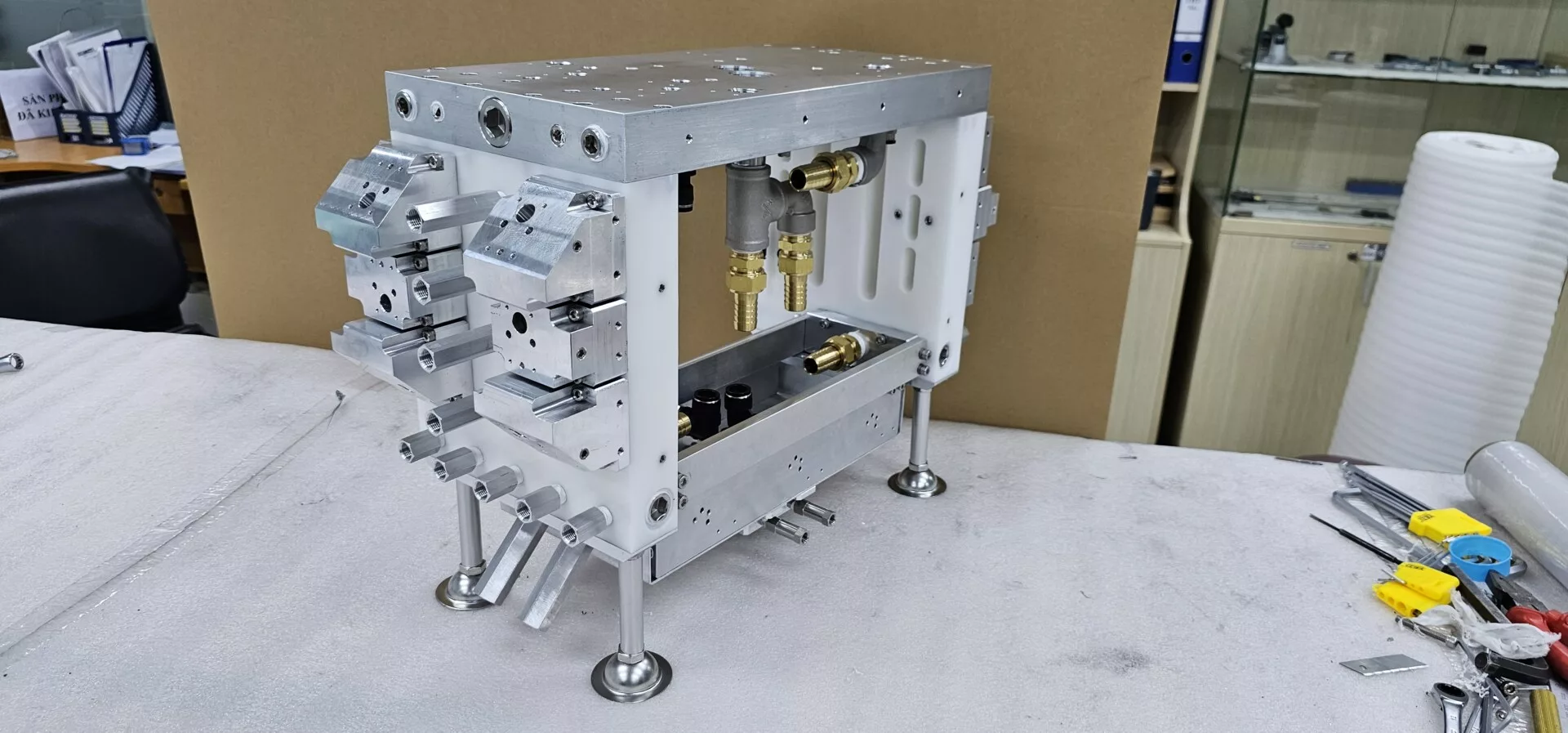

From creating intricate components to rapid tooling, 3D printing has found extensive applications in machine prototyping. This technology enables the production of functional prototypes that closely resemble the final product, allowing for rigorous testing and validation before mass production.

As a leader in industrial machine design and manufacturing, IDEA offers comprehensive services in machine prototyping utilizing 3D printing technology. Partner with us to leverage the benefits of rapid prototyping and expedite your product development process.

Visit IDEA’s website to learn more about our cutting-edge solutions in machine design and drafting services.

For advanced automation services, check out our partners at chetaomayidea and ideatechmart.